A multifunctional down filling workbench of a down filling machine for garment processing

A multi-functional, workbench technology, applied in the direction of sewing tools, etc., can solve the problems of flying fluff, inconvenient movement, and inability to adjust the height, so as to achieve the effect of convenient operation and increased vacuum function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

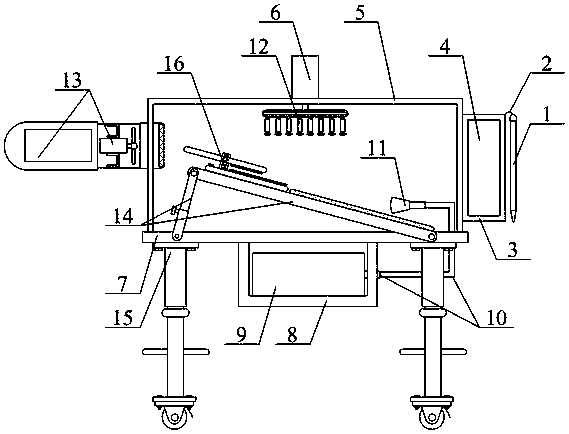

[0054] as attached figure 1 to attach Figure 6 shown

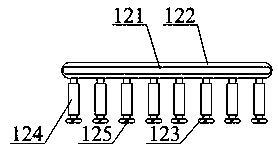

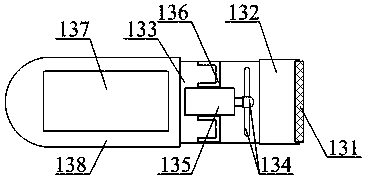

[0055] The present invention provides a multifunctional down filling workbench of a down filling machine for garment processing, comprising a recording pen 1, a connecting rope 2, a fixing plate 3, a recording plate 4, a hemispherical opening shield 5, a down winding motor 6, and a base 7 , U-shaped fixing seat 8, down filling machine 9, down guide tube 10, down filling nozzle 11, detachable down shaft winding structure 12, vacuum storage conduit structure 13, adjustable clothing placement frame structure 14, adjustable moving wheel structure 15 and an adjustable clothing clamping plate structure 16, the recording pen 1 is connected to the right side of the fixing plate 3 through the connecting rope 2; the recording plate 4 is glued longitudinally in the middle of the front surface of the fixing plate 3; The hemispherical opening shield 5 bolts are installed in the upper middle position of the base 7; the described velv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com