High-temperature drying device for new chemical materials

A high-temperature drying, new material technology, applied in heating devices, drying solid materials, drying cargo handling, etc., can solve the problems of lack of bottom height, slow drying speed, inconvenient protective effect, etc., to improve drying effect, avoid The effect of scalding, improving the flipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

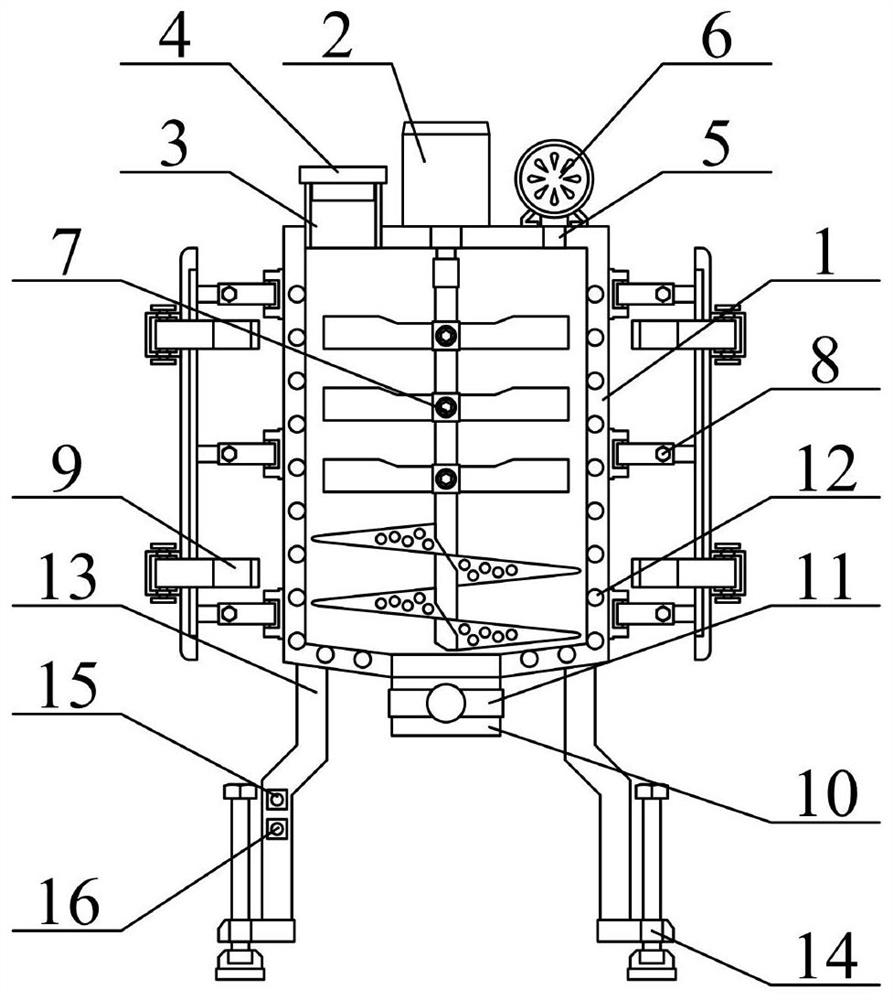

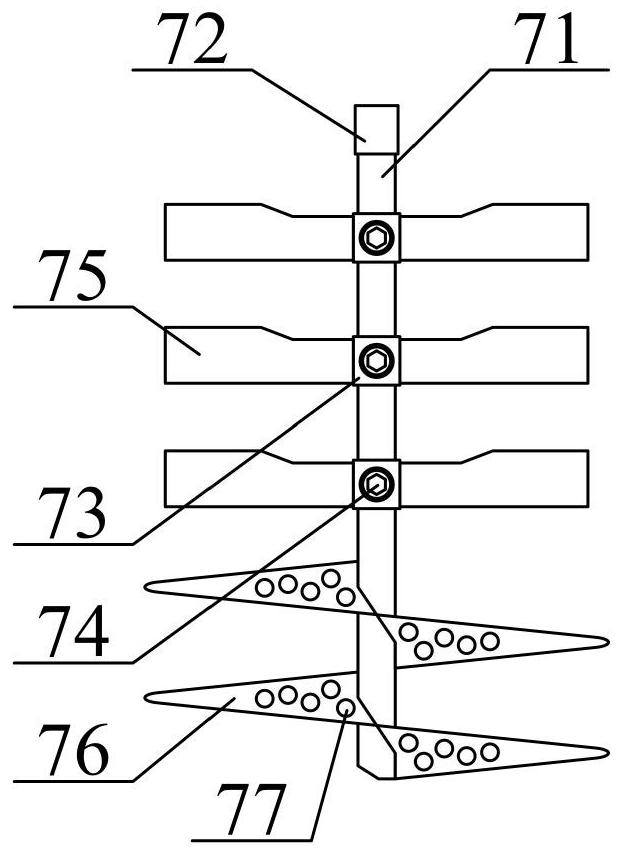

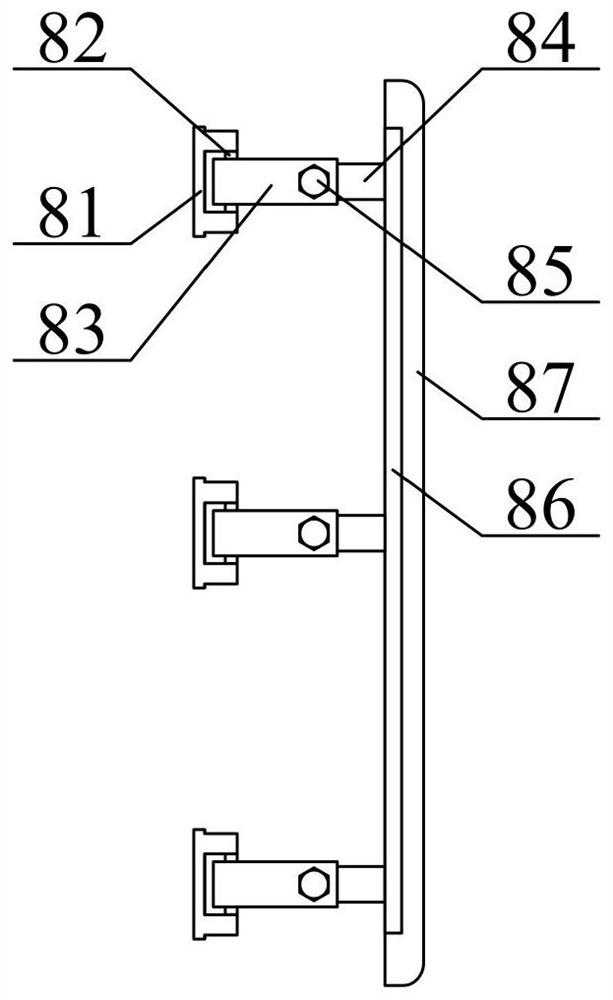

[0040] as attached figure 1 And attached image 3 shown

[0041]The invention provides a high-temperature drying device for new chemical materials, including a drying mixing drum 1, a mixing motor 2, a feeding pipe 3, a sealing cover 4, a discharge pipe 5, a discharge fan 6, and an adjustable stirring and turning frame structure 7 , adjustable side protection frame structure 8, adjustable protective belt structure 9, outlet pipe 10, outlet valve 11, electric heating pipe 12, bottom bracket 13, height adjustable bracket structure 14, power switch 15 and fan switch 16, the The mixing motor 2 bolts are installed in the middle and upper part of the drying mixing drum 1; the feeding pipe 3 is inserted in the upper left side of the drying mixing drum 1; the sealing cover 4 is inserted in the inner side of the feeding pipe 3 The upper part; the discharge pipe 5 is plugged into the upper right side of the drying mixing drum 1; the discharge fan 6 bolts are installed on the upper rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com