Building construction gravel screening device capable of controlling screen holes

A technology for building construction and screening devices, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of low efficiency, large area occupied by sand screening devices, and the inability to change the size of sand screening at will. Achieve the effect of improving screening efficiency and avoiding mesh blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

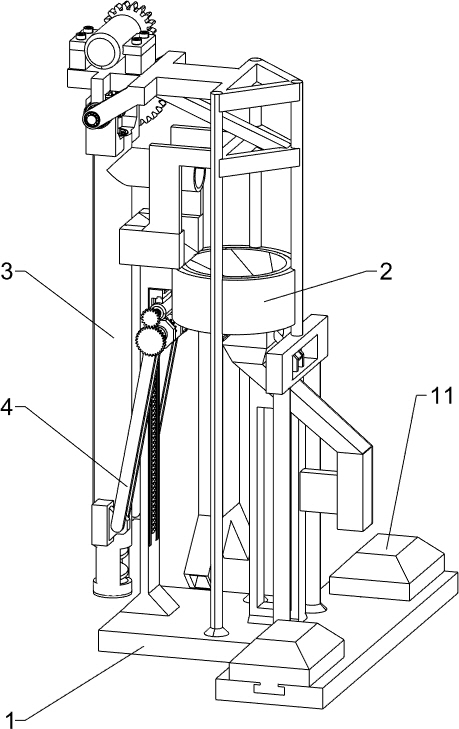

[0036] Please refer to figure 1 As shown, a sand and gravel screening device with controllable sieve openings for building construction includes a bottom plate 1, a separation mechanism 2 and a circulating feeding mechanism 3. A separation mechanism 2 is installed on the top of the bottom plate 1, and the top of the bottom plate 1 on the left side of the separation mechanism 2 A circulating feeding mechanism 3 is provided, and the circulating feeding mechanism 3 is connected with the separation mechanism 2 .

[0037] When sand and gravel need to be screened, the user places the present invention at a suitable position on the right side of the sand and gravel pile, then the user swings the circulating feeding mechanism 3 to the left, inserts the lower part of the circulating feeding mechanism 3 into the sand and gravel pile, and then The user starts the circulation feeding mechanism 3 to work, and the circulation feeding mechanism 3 can transport the sand and gravel upwards to ...

Embodiment 2

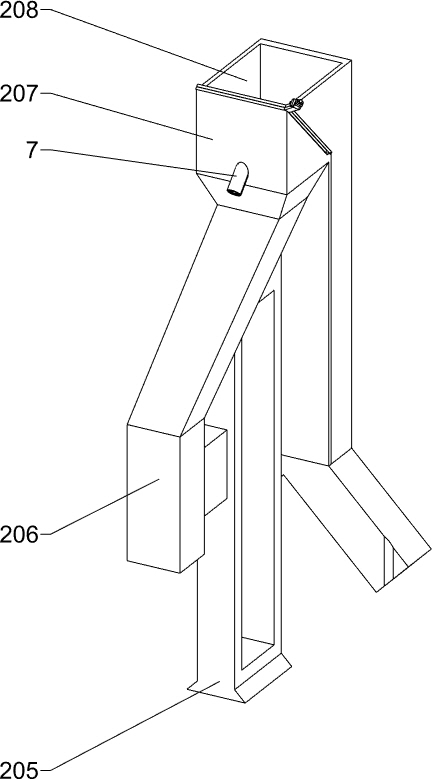

[0039] Please refer to Figure 2-Figure 4 As shown, on the basis of Embodiment 1, the separation mechanism 2 includes a fixed frame 201, a trough-shaped eccentric frame 202, a support frame 205, a first blanking pipeline 206, a blanking frame 207, a second blanking pipeline 208, a flow divider Pipeline 2081 and screening parts, fixed frame 201 are connected on the left side of the top of bottom plate 1, and the upper inner side of fixed frame 201 is fixedly connected with groove-shaped eccentric frame 202, and the top of bottom plate 1 on the right side of fixed frame 201 is equipped with support frame 205, and support frame The top of 205 is equipped with the first blanking pipeline 206, and the top of the first blanking pipeline 206 is equipped with blanking frame 207, and the left side wall of blanking frame 207 is provided with the second blanking pipeline 208, and the second blanking pipeline 208 A shunt pipeline 2081 is installed at the bottom of the bottom, and a screen...

Embodiment 3

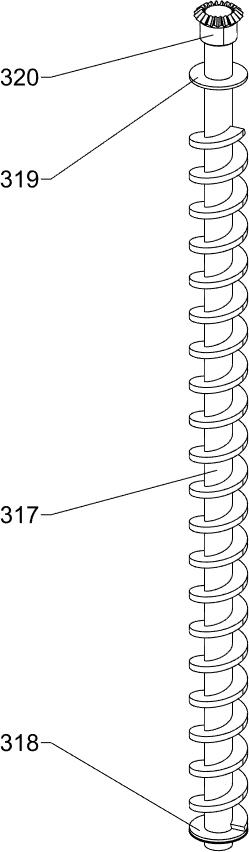

[0044] Please refer to Figure 5-Figure 8 As shown, on the basis of Embodiment 2, the circular feeding mechanism 3 includes a first pole 301, a second pole 3011, a hollow frame 3012, a third pole 302, a mounting frame 303, a trough 304, a first Gear motor 305, first gear 306, first rotating shaft 307, second gear 308, axle sleeve 309, first bearing seat 310, second bearing seat 311, connecting frame 312, first bevel gear 313 and feeding parts, the first One pole 301 is provided with two, and two first poles 301 are fixedly connected on the front and rear sides of the bottom plate 1 top, and the front and rear two first poles 301 are located between the fixed frame 201 and the support frame 205, and the support frame 205 Second poles 3011 are installed on the tops of the base plates 1 on the front and rear sides, a hollow frame 3012 is fixedly connected between the upper ends of the two second poles 3011, and a third pole 302 is installed on the top of the hollow frame 3012. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com