A Novel Repeating Ballista and Its Continuous Shooting Method

A bursting crossbow machine, a new type of technology, applied in the direction of bow/crossbow, weapon types, weapons without explosives, etc., can solve the problems of reducing operating force, deviating from the concept of cold weapon manufacturing and artistic aesthetic value, and unfavorable market promotion. The effect of increasing the stock of arrows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

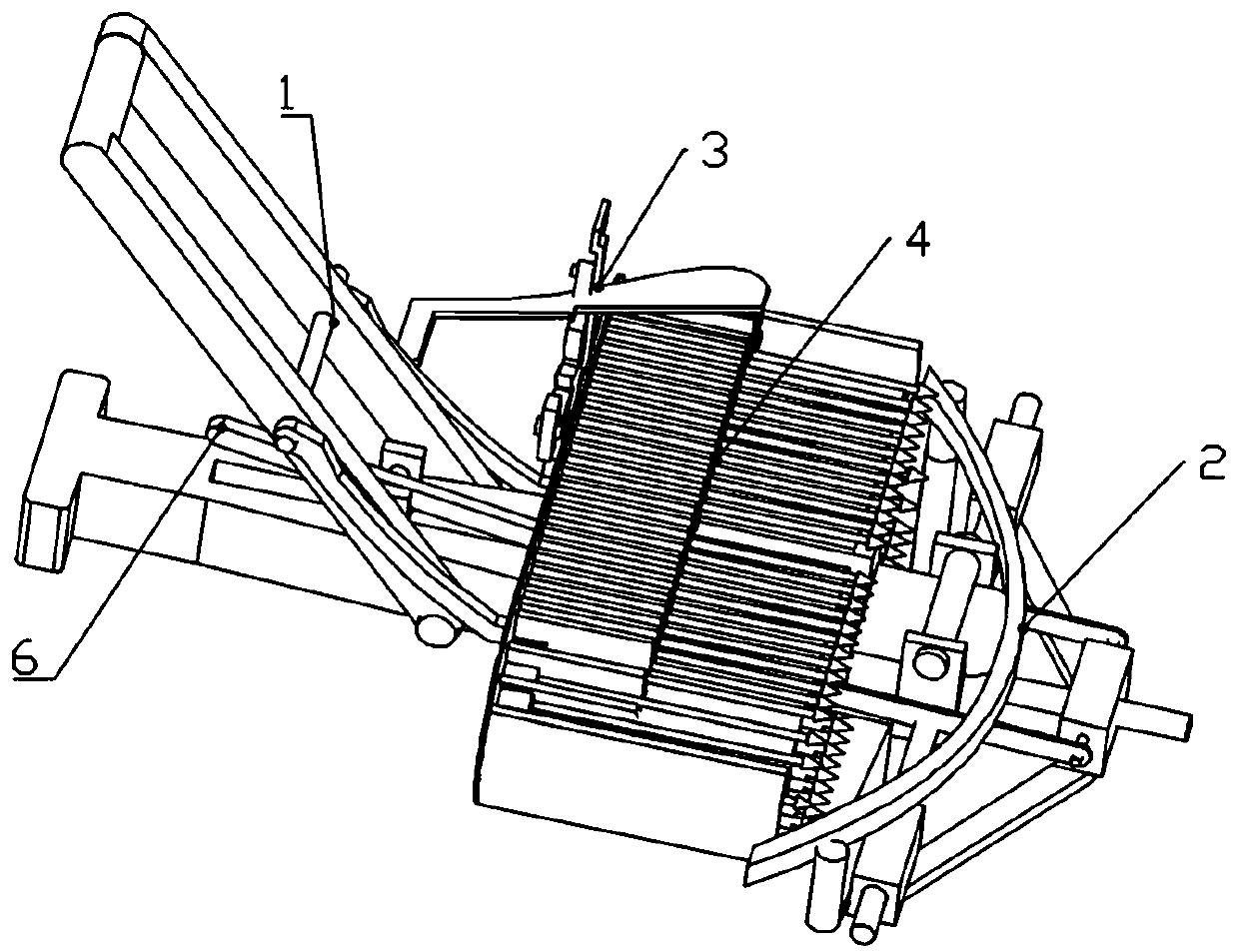

[0034] Such as figure 1 As shown, the new type of continuous firing crossbow machine includes a winding mechanism 1, a bow pressing arm mechanism 2, a periodic arrow shifting mechanism 3, an arrow storage and loading mechanism 4, and a trigger mechanism 5. The winding mechanism 1 passes through the first moving pair 17 and the slotted connecting piece 21 Connect the bow pressing arm mechanism 2, cooperate with the periodic arrow shifting mechanism 3 through the hinged disc cam 31 on the upper chord 11, the arrow storage and loading mechanism 4 is supported by the crossbow seat 14 as a whole, and the arrow drop slot 44 is connected with the crossbow seat 14 The arrow loading place of front end bow arm 13 is aligned up and down.

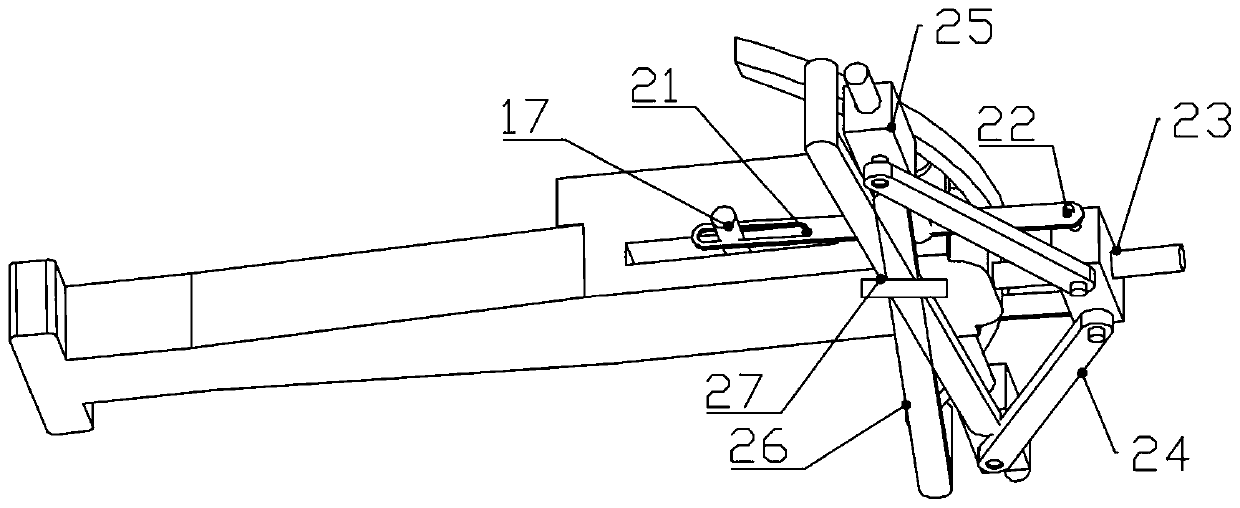

[0035] Such as figure 2 As shown, the winding mechanism includes a winding rod 11, a hooking rod 12, a bow arm 13, a crossbow seat 14, a first rotating pair 15,

[0036] The second rotating pair 16, the first moving pair 17, the middle and lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com