High Viscosity Base Stock Composition

A base oil and composition technology, which is applied in the production of lubricating compositions, base materials, and liquid hydrocarbon mixtures, and can solve the problems of expensive production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

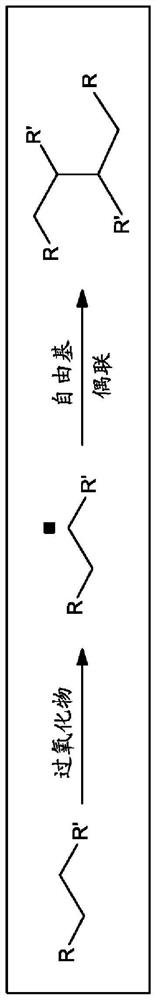

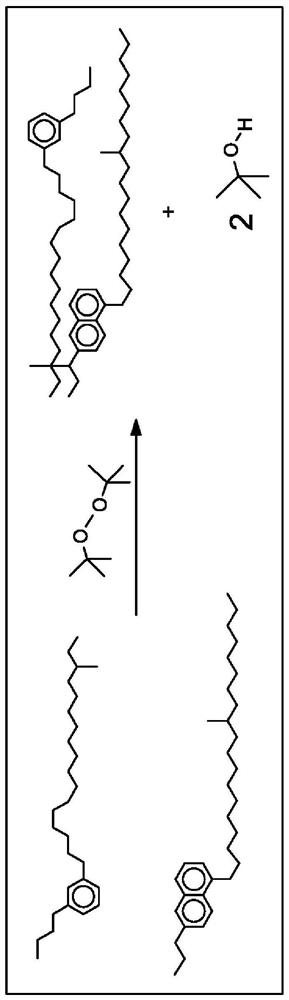

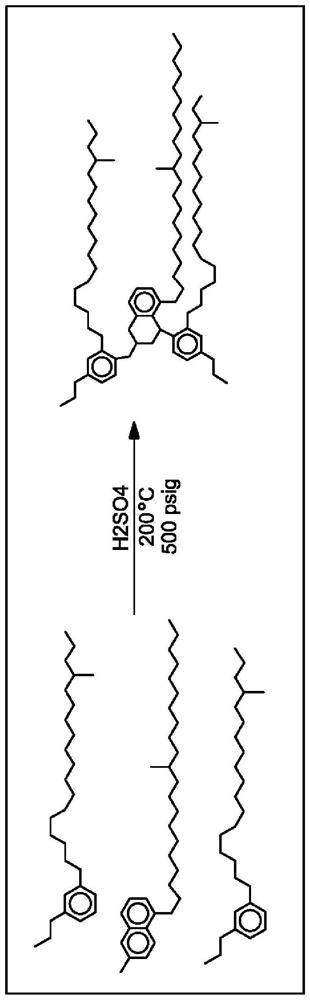

Method used

Image

Examples

Embodiment 1

[0109] The sulfur content of Examples 1-6 is similar to that expected for typical Group II base stocks. This differs from typical Group I bright stocks which often have significant sulfur content.

[0110] The high viscosity base stocks described herein may also have an unexpectedly high aniline point relative to the viscosity of the base stock. Such as Figure 9 As shown in , Examples 1-6 each have an aniline point of at least 130°C (measured according to ASTM D611). This is different from Figure 9 The aniline points of the conventional base stocks shown in , each having an aniline point close to 120°C.

[0111] exist Figure 11 The unexpected aniline point properties can also be seen in . Figure 11 A logarithmic scale graph showing kinematic viscosity at 100°C vs. aniline point for various base stocks. Figure 11 The squares in correspond to Examples 1 to 6, which are high viscosity base stocks synthesized by coupling reactions as described herein. The diamonds corr...

Embodiment 5

[0115]Example 5: Lubricant Formulations - Gear Oil Properties

[0116] In addition to the above physical and chemical properties, high viscosity base stocks can provide other types of improved properties. In this example, an ISO VG 220 gear oil was formulated using a high viscosity base stock corresponding to Example 3. ISO VG 220 gear oils were also formulated using conventional CORE 2500 Group I bright stock. Both gear oils were used with the same additive package in the same amount and the same rebalanced light neutral base stock to make the desired viscosity grade. Two formulation performance characteristics were measured. One measured characteristic is Brookfield Viscosity at -20°C using ASTM test method D2983-13 Low Temperature Properties. The second measurement characteristic is the oxidative stability of US Steel oxidation at 121°C for 13 days using ASTM test method D2983-2.

[0117] Figure 12 Shown is a comparison of Brookfield viscosities at -20°C for gear oils...

Embodiment 6

[0119] Example 6: Lubricant Formulations - Gear Oil Properties

[0120] In this example, an ISO VG220 gear oil was formulated using a high viscosity base stock corresponding to Example 3. A second ISO VG 220 gear oil was also formulated using conventional CORE 2500 Group I bright stock. A third ISO VG220 gear oil was formulated using the polyalphaolefin base stock indicated in the last row of Table 1 . Use the same amount of the same additive package and the same rebalanced light neutral base stock on the formulated gear oil to make the desired viscosity grade. Two formulation performance characteristics were measured. One measured characteristic is Brookfield Viscosity at -35°C using ASTM test method D2983 Low Temperature Properties. The second measurement characteristic is the oxidation stability using ASTM test method D2272, Rotating Pressure Vessel Oxidation Test (RPVOT) at 150°C.

[0121] Figure 14 Shows the performance at -35°C for a gear oil formulated using conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com