Tail removal machine for spiral shells

A technology of tail machine and snail, which is applied in the field of snail tail cutting machine, and can solve the problem that the tail of snail cannot be guaranteed to be completely removed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

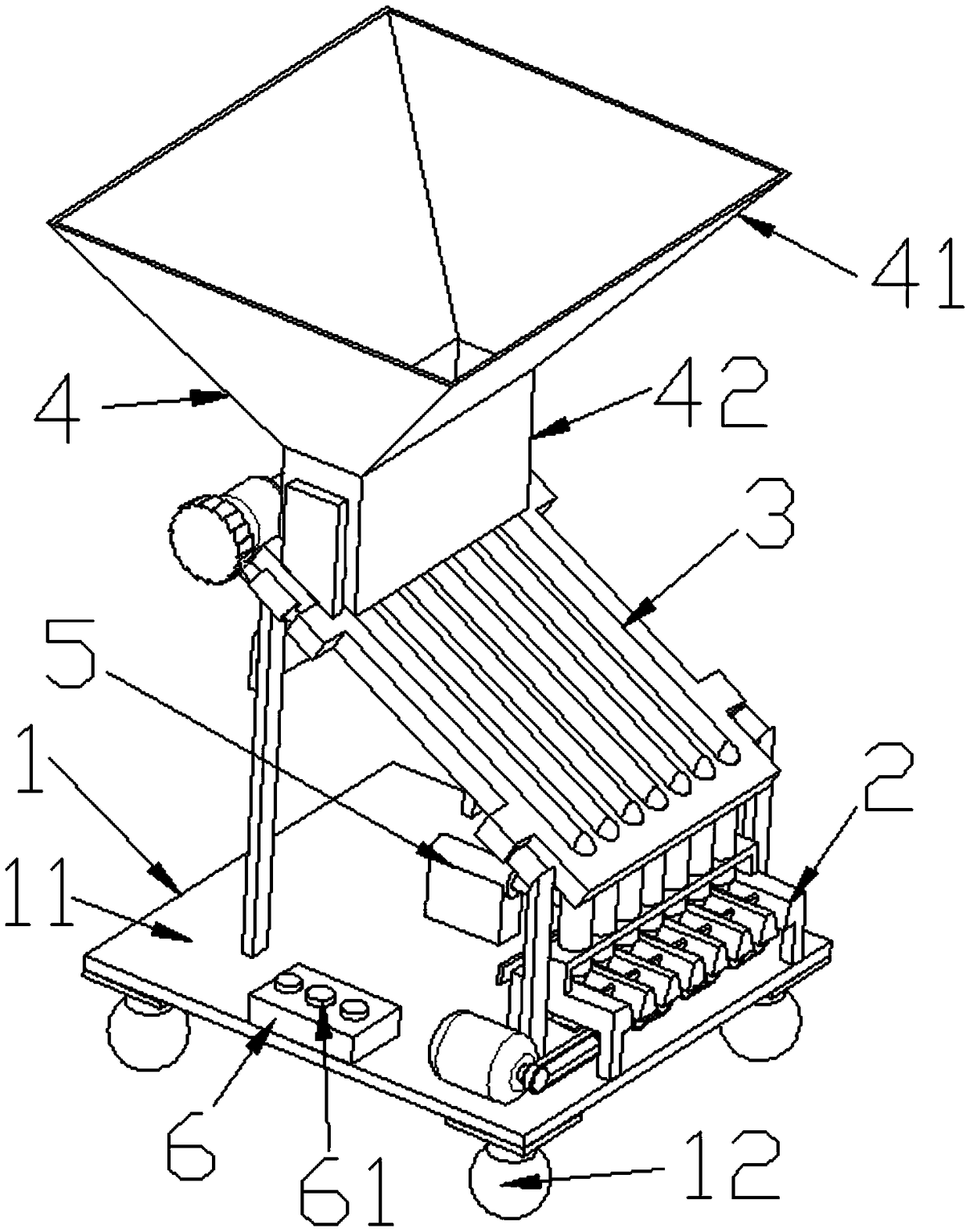

[0036] Such as Figure 1 to Figure 9 As shown, a snail tail removal machine is characterized in that it includes a base part 1, a tail removal part 2, a screening part 3, a funnel part 4, a pushing mechanism 5, and a control device 6;

[0037] The base part 1 includes a base plate 11;

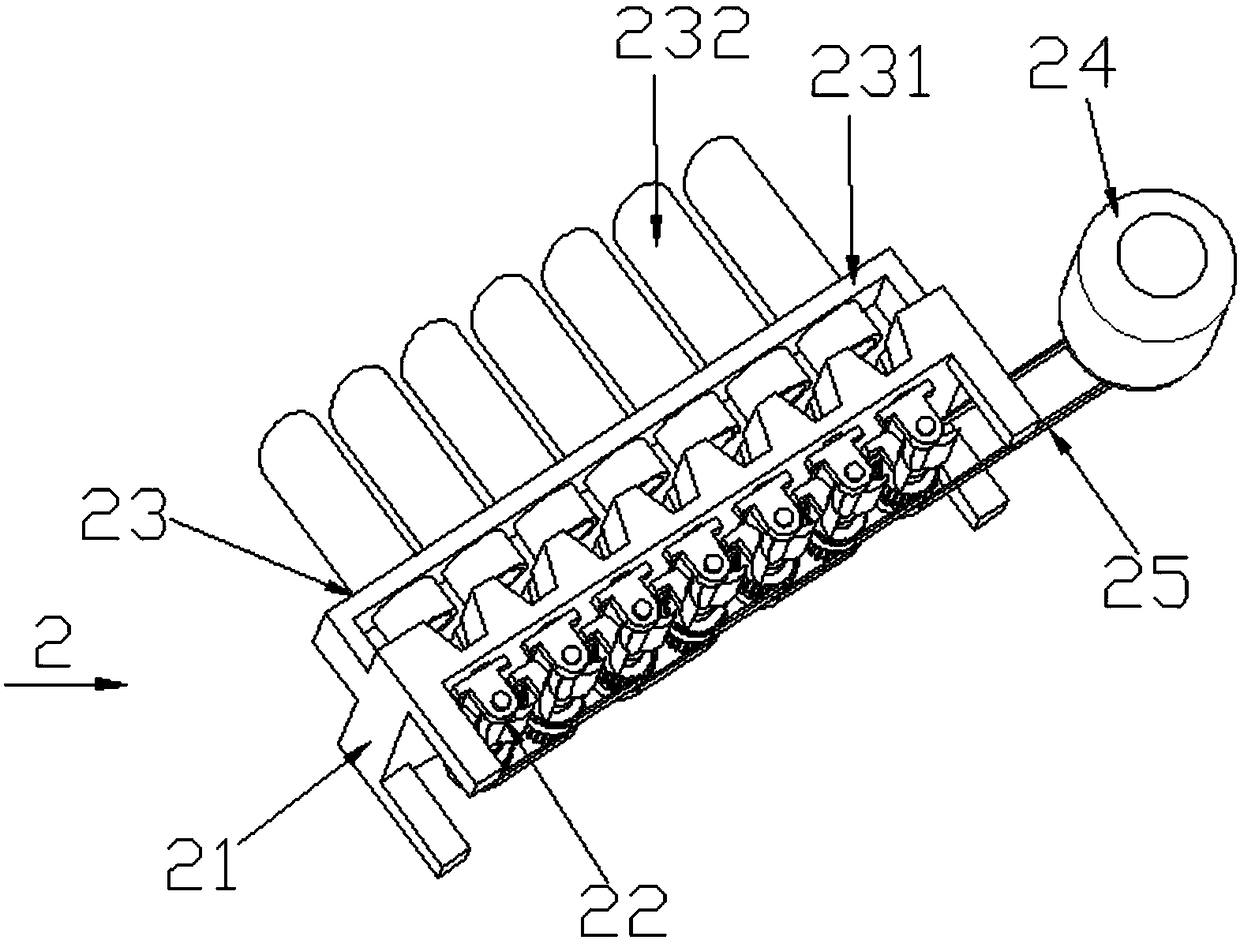

[0038] The tail removal part 2 includes a tail removal platform 21, a tail removal knife assembly 22, a feeding tube assembly 23, and a drive motor 24;

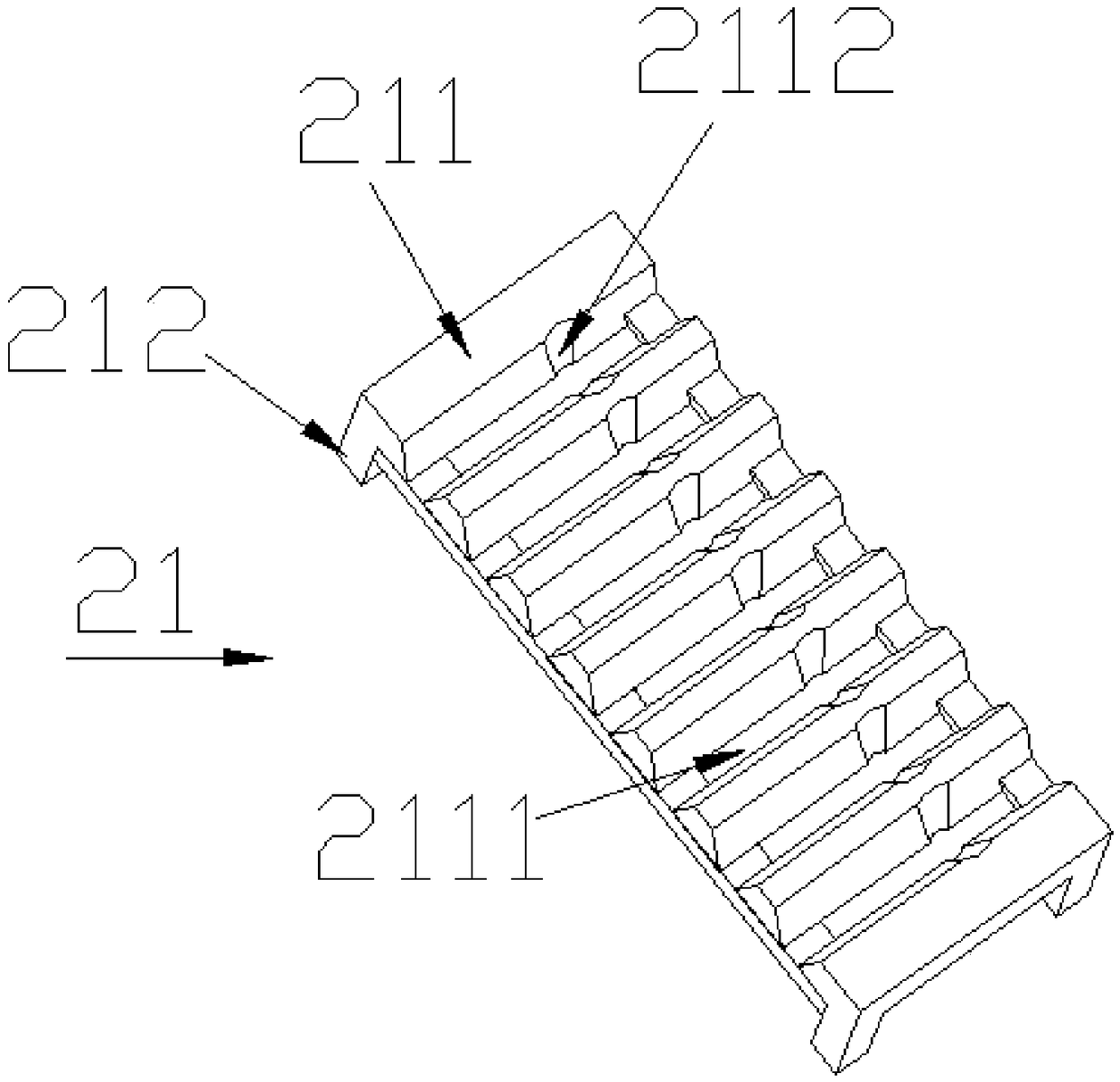

[0039] The tail-removing platform 21 includes a placement plate 211, the placement plate 211 is horizontally provided with a plurality of first trapezoidal grooves 2111, the first trapezoidal grooves 2111 are provided with conical grooves 2112, and support legs are provided below the placement plate 211 212; the supporting legs 212 are fixed above the base plate 11;

[0040] The feeding tube assembly 23 includes a feeding tube 231, and the feeding tube 231 is vertically arranged directly above the conical groove portion 2112, and a feeding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com