A device for removing tails of nails and screws for food processing

A technology for food processing and oncomelania, which is applied in the field of oncomelania tailing devices for food processing, and can solve the problems of low tailing efficiency, heavy workload and labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

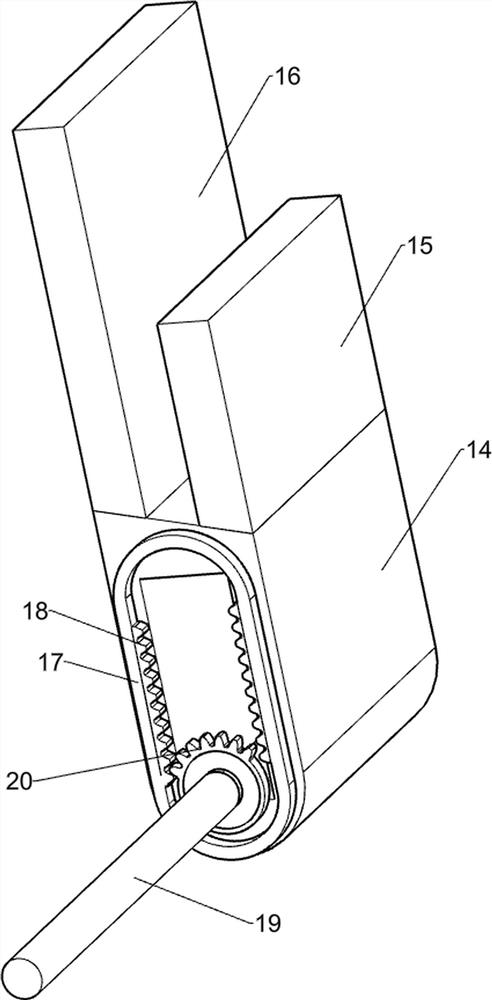

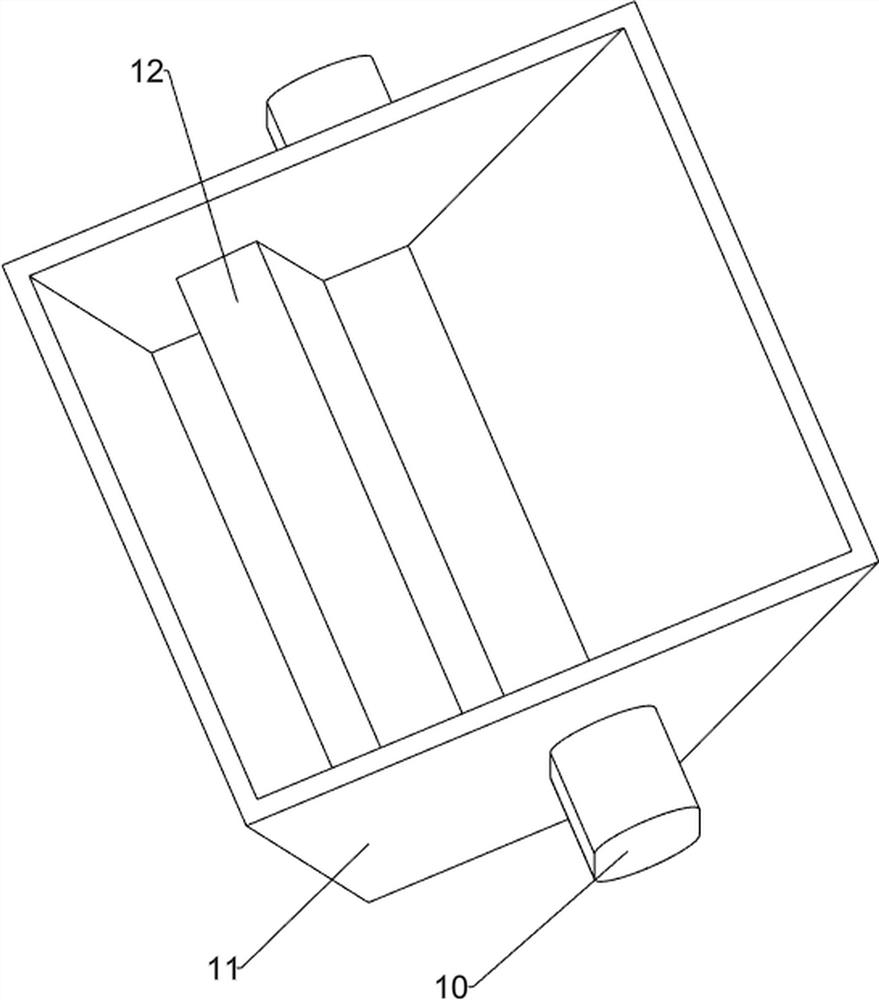

[0024] A kind of screw tail removal device for food processing, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a base 1, a transmission mechanism 2, a hammering mechanism 3 and a collection frame 4. The top of the base 1 is provided with a transmission mechanism 2, the right side of the top of the base 1 is provided with a hammering mechanism 3, and the right side of the top of the base 1 is provided with a collection frame. Frame 4, the collecting frame 4 is located on the right side of the hammering mechanism 3 .

[0025] When people need to use this device, first people put the snails evenly on the transmission mechanism 2, then start the transmission mechanism 2 to make the transmission mechanism 2 work, the transmission mechanism 2 then transmits the snail shape to the right, and wait for the snails to move to the hammering mechanism 3, the transmission mechanism 2 drives the hammer mechanism 3 to operate, so that the hammer mechanism 3 squ...

Embodiment 2

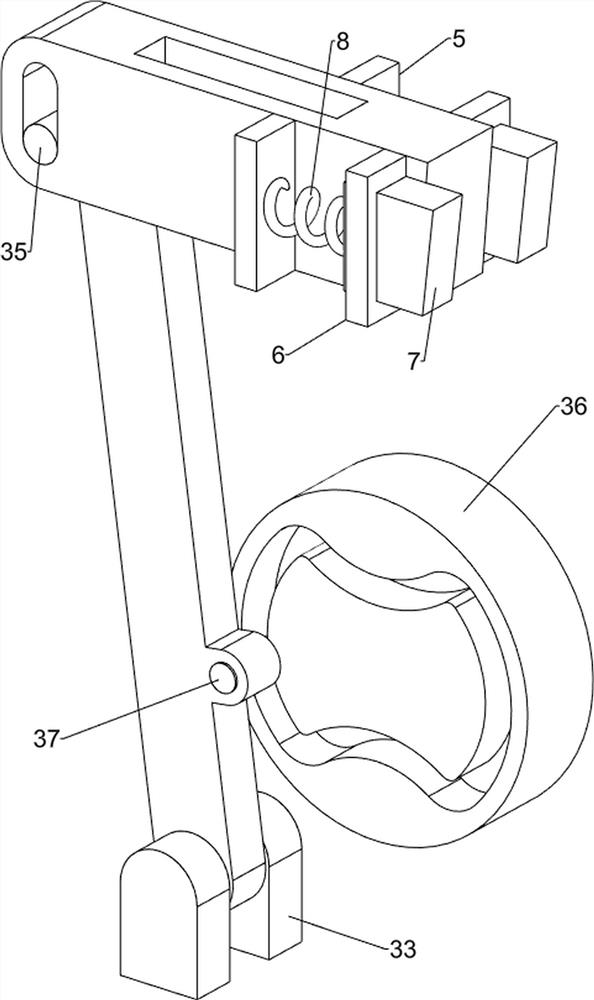

[0031] On the basis of Example 1, such as Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, it also includes a first fixed plate 5, a second fixed plate 6, a second slider 7 and an elastic member 8, and the first fixed plate 5 is symmetrically arranged on the first slider 32. After the first slider 32 The left and right sides are symmetrically provided with a second fixed plate 6, the second fixed plate 6 is located at the rear side of the first fixed plate 5, and the second fixed plate 6 is provided with a second slide block 7 in a sliding manner, and the second slide block 7 and An elastic member 8 is disposed between the first fixing plates 5, and the elastic member 8 is a compression spring.

[0032] When the first slide block 32 moved backward, the first slide block 32 drove all parts on it to move backward, because the second slide block 7 would be in contact with the baffle plate 38 first, so the second slide block 7 would limit the screws. In front of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com