Rotating throwing device and multi-angle throwing method

A technology of rotating rods and mounting plates, applied in the direction of sports accessories, etc., can solve problems such as lack, and achieve the effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

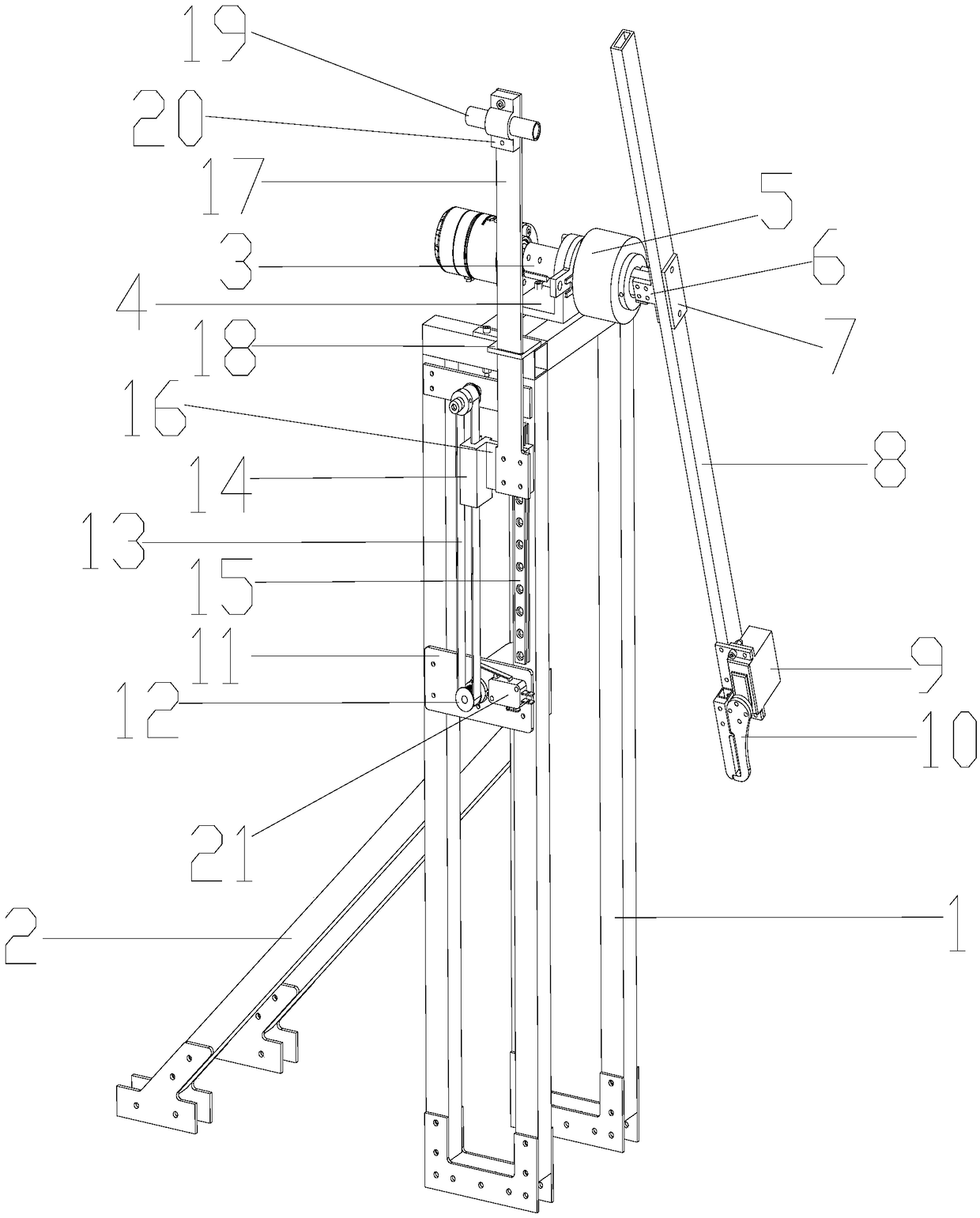

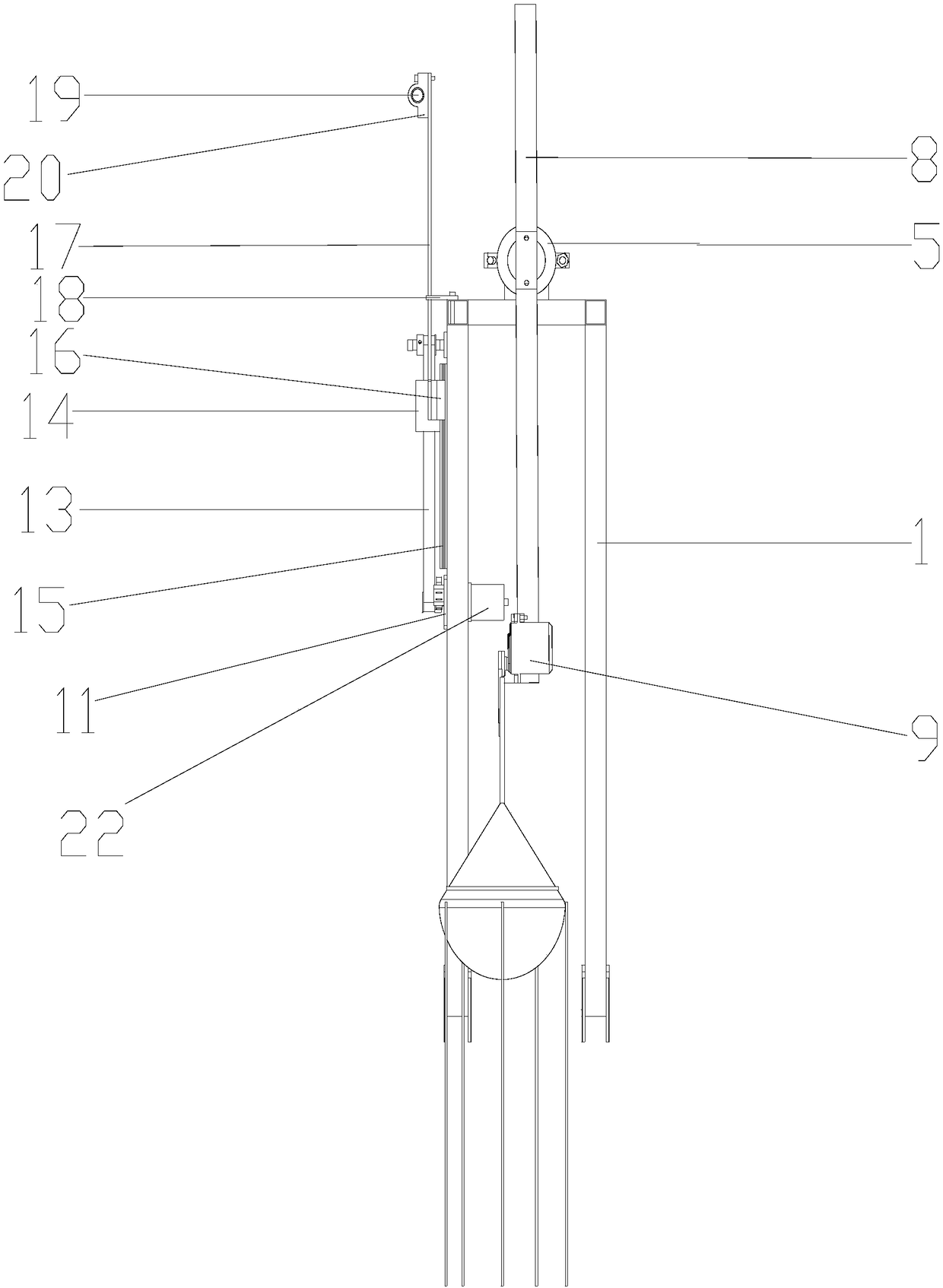

[0031] like figure 1 and figure 2 As shown, a rotating projectile device in this embodiment includes a frame 1, a drive motor 3, a motor base 4, a conductive slip ring 5, a connecting corner code 6, a connecting block 7, a rotating rod 8, a steering gear 9, and an air gripper 10 , Mounting plate 11, synchronous belt structure, extension plate 17, extension plate limit block 18, laser sensor 19, laser fixing seat 20, guide rail 15 and slide block 16.

[0032] One side of the frame is provided with an inclined support frame 2, which can improve the stress on the frame and reduce the vibration caused when the rotating rod rotates.

[0033] like figure 1 and figure 2 As shown in the figure, the motor seat is installed on the top of the frame, and the driving motor is installed on the motor seat. The output end of the driving motor is connected to the conductive slip ring through the plum blossom coupling. The conductive slip ring is connected to the connecting block through ...

Embodiment 2

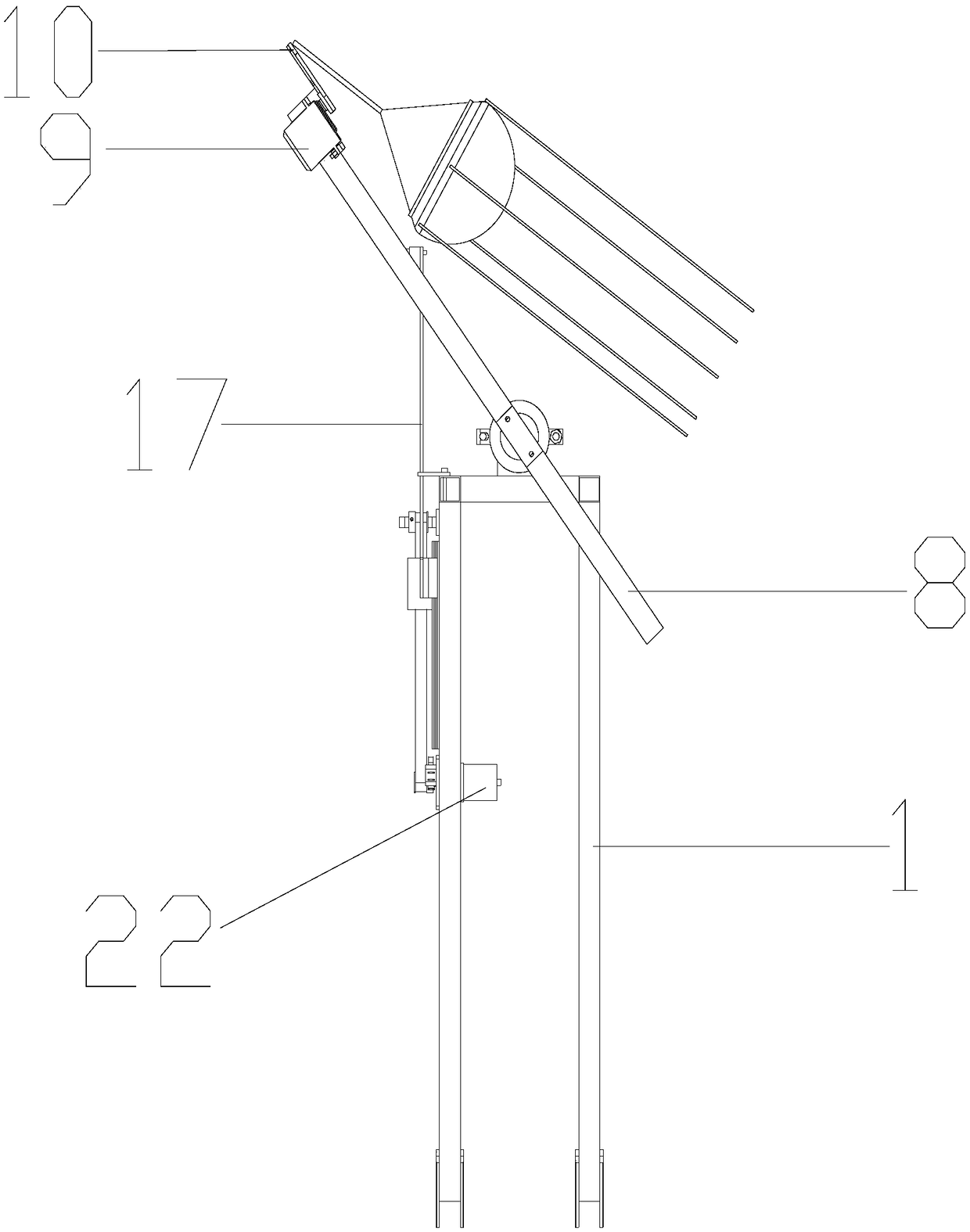

[0038] like image 3 , Figure 4 , Figure 5 and Image 6 As shown, this embodiment is a multi-angle projecting method of the rotary projecting device described in Embodiment 1, comprising the following steps:

[0039] a. After the rotary projecting device is powered on, the extension plate moves downward until the extension plate triggers the positioning switch to initialize the laser sensor, and then the synchronous belt structure drives the extension plate to move up and down until the height of the laser sensor reaches the set height ;

[0040] b. The drive motor drives the conductive slip ring to rotate, thereby driving the rotating rod to rotate;

[0041] c. When the laser sensor detects the laser light reflected from the rotating rod, control the steering gear to release the air claws to release the object, and the object ejection is completed so far.

[0042] By setting the laser sensor at different heights and controlling the rotating rod to project objects at di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com