Machine for cutting tubes

A hose and machine technology, applied in the field of cutting devices, can solve problems such as the decrease in reliability of hydraulic pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

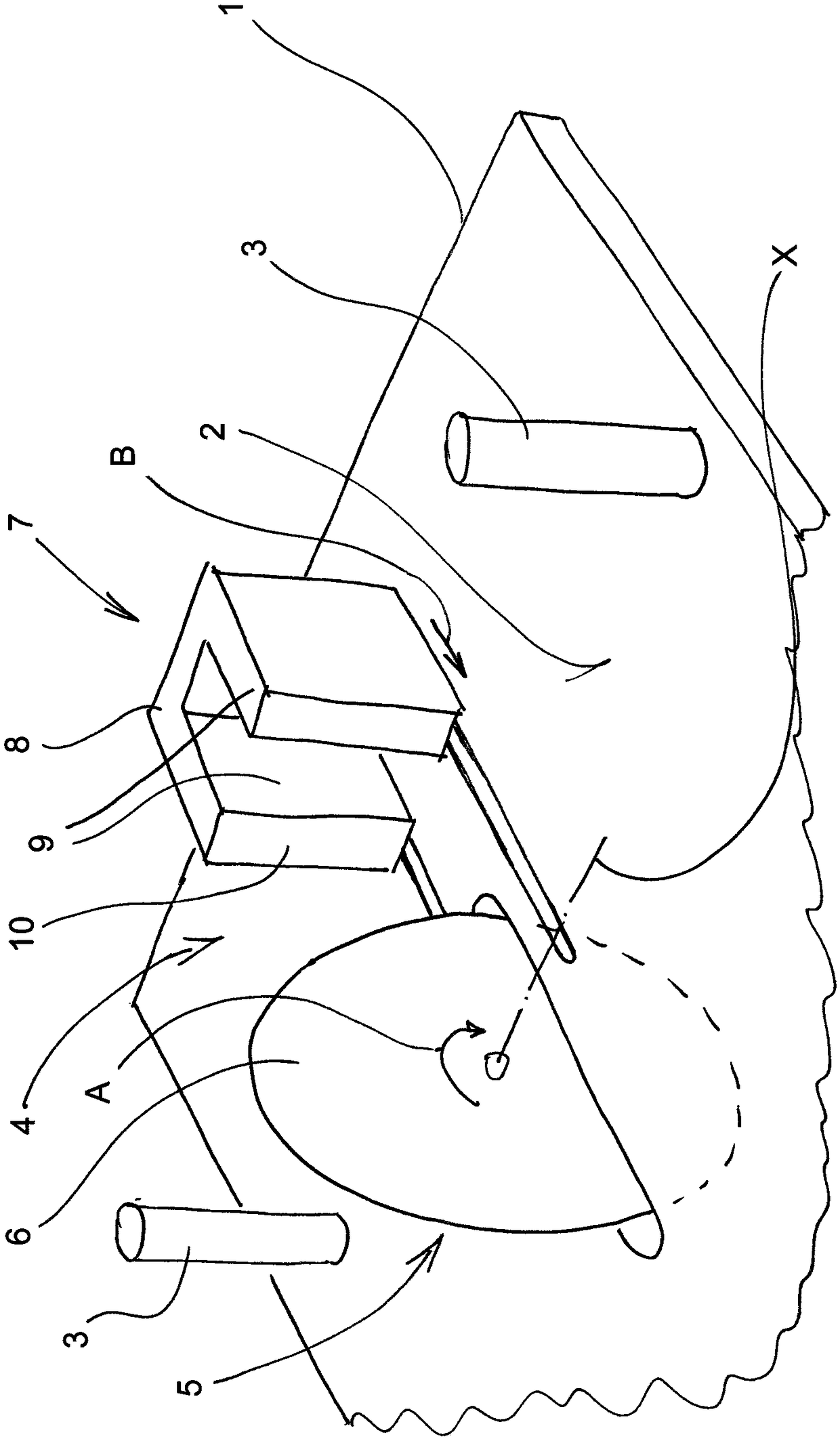

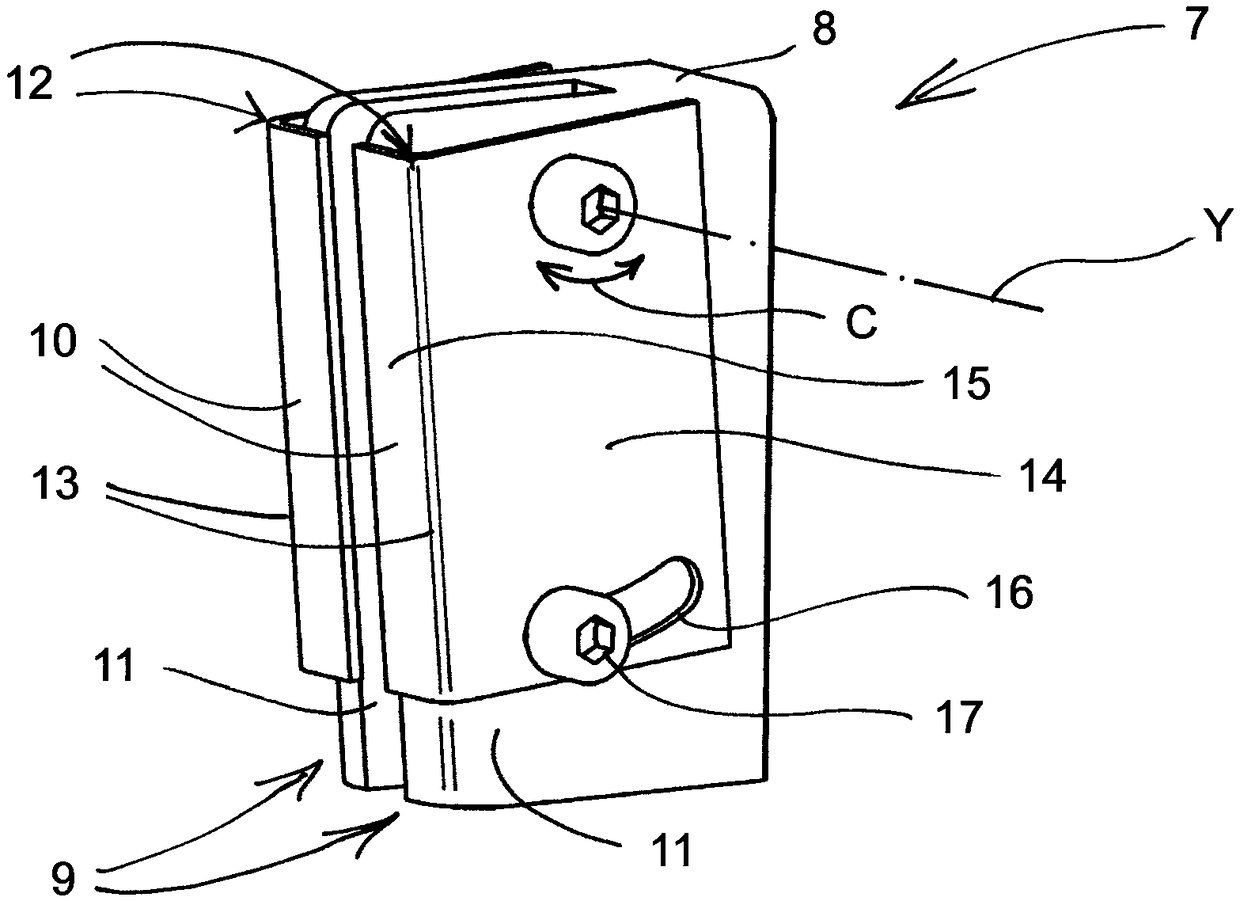

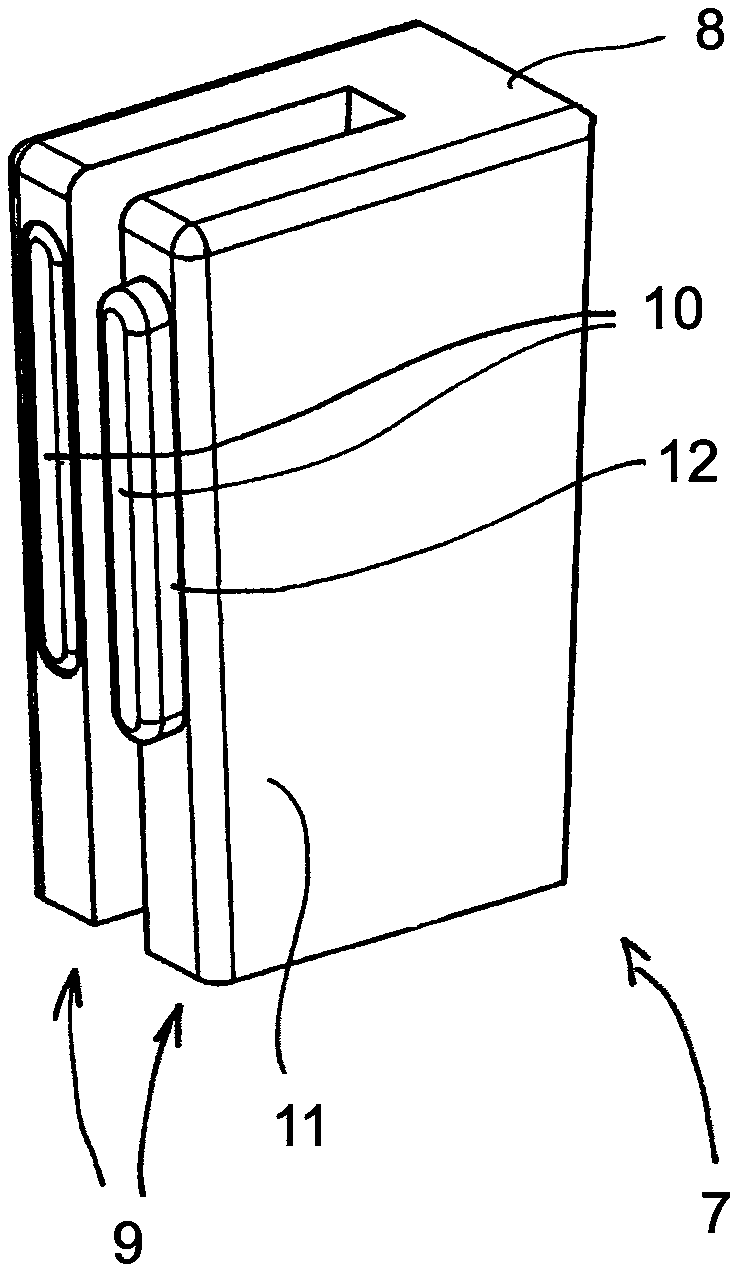

[0019] As known in the prior art (cf. for example GB 1505113) and therefore need not be specifically set forth, figure 1 The machine for cutting hoses shown schematically in includes a placement table 1 with a substantially planar hose placement surface 2, two spaced apart hose devices 3 protruding from the placement table and arranged on the hose Cutting device between equipment4. The latter comprises a sectioning tool 5 in the form of a sectioning segment 6 which is driven in rotation (arrow A) about an axis X substantially parallel to the hose placement surface 2 and which defines the A substantially vertical cutting plane. Furthermore, the sectioning device 4 includes a hose feed 7 which is movable (arrow B) parallel to the sectioning plane and parallel to the hose placement surface 2 by means of a feed mechanism (not shown) arranged below the placement table 1 . As a one-piece, substantially U-shaped feed seat 8 in horizontal section, the hose feed has two pressure part...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap