Gear rail wheel height adjusting mechanism and gear rail wheel driving device

A technology of height adjustment mechanism and rack wheel, applied in locomotives, motor vehicles, locomotive propulsion methods, etc., can solve the problem of shortening the wheel replacement cycle and service life of rack wheels, short wheel life of rack wheels, and limiting the use of rack vehicles Issues such as range and performance, to achieve the effect of increasing the use limit range, prolonging the replacement cycle and service life, and expanding the use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

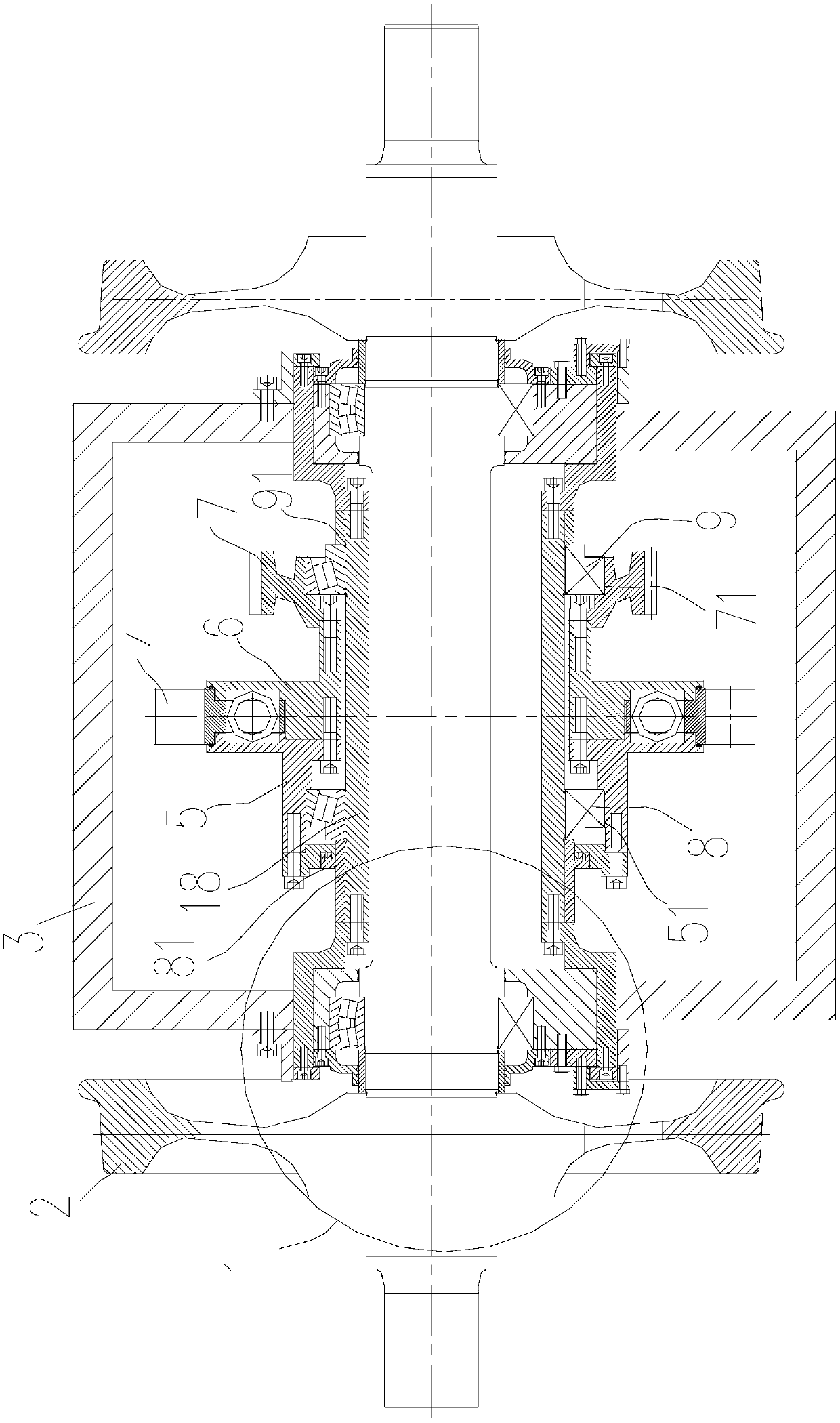

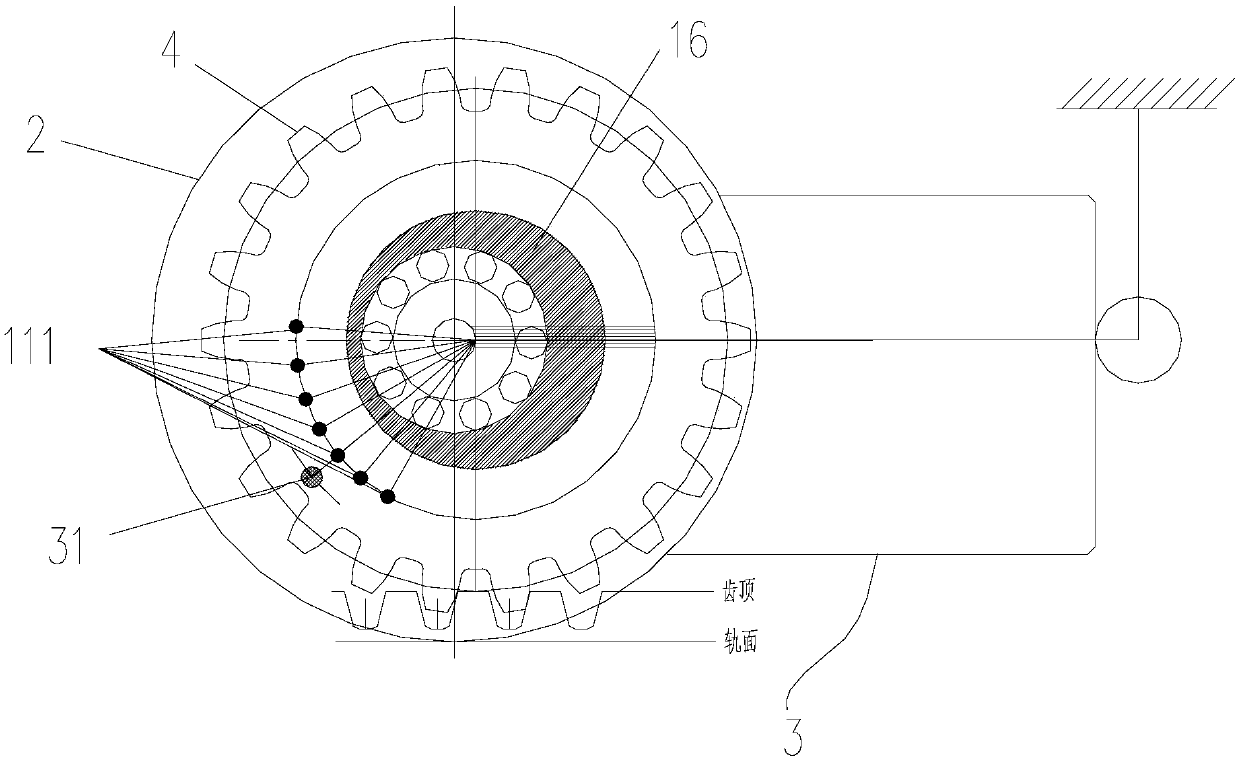

[0031] Such as figure 1 and 2 As shown, the rack wheel drive device of this embodiment includes an axle 10, wheels 2 installed at both ends of the axle 10, a rack wheel height adjustment mechanism 1 and a rack wheel assembly.

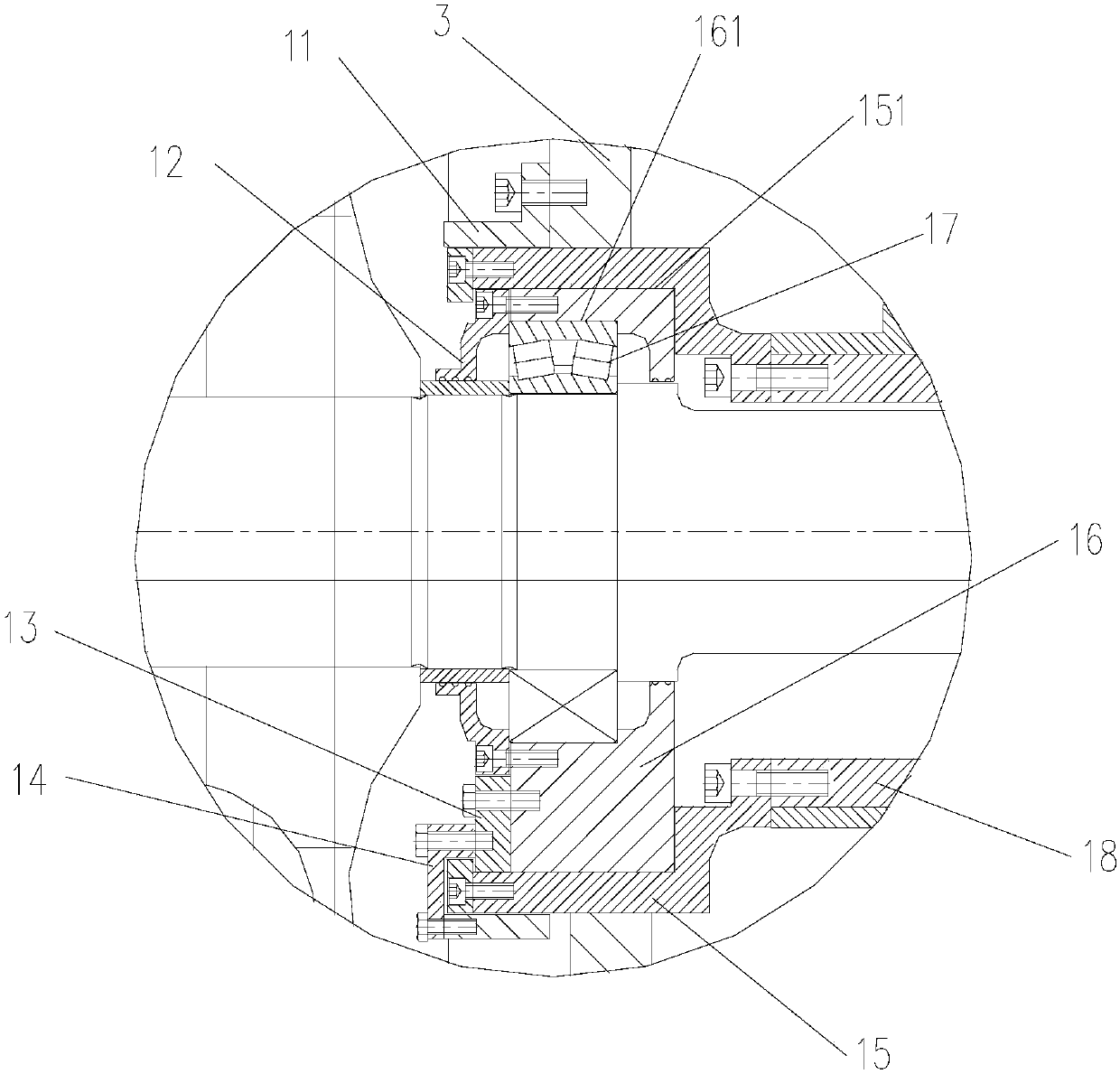

[0032] The rack wheel height adjustment mechanism 1 is installed on the axle 10 and is located between the wheel 2 and the rack wheel 4 . The rack wheel height adjustment mechanism 1 includes an eccentric adjustment assembly and a hollow shaft 18 . In this embodiment, there are two eccentric adjustment assemblies, and the two eccentric adjustment assemblies are respectively arranged at both ends of the rack wheel 4 .

[0033] The eccentric adjustment assembly includes an adjustment ring 11 , a first bearing cover 12 , a first connecting plate 13 , a second connecting plate 14 , a hollow shaft head 15 , an eccentric wheel 16 and a spherical roller bearing 17 .

[0034] Among them, the hollow shaft 18 is sleeved on the axle 10, and the rack wheel assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com