Sewage suction equipment and sewage suction operation method for cleaning river sludge

A sludge and river technology, applied in separation methods, chemical instruments and methods, mechanically driven excavators/dredgers, etc., can solve the problems of low sewage suction efficiency, screening out solid impurities, low efficiency, etc. Reasonable, easy to operate, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

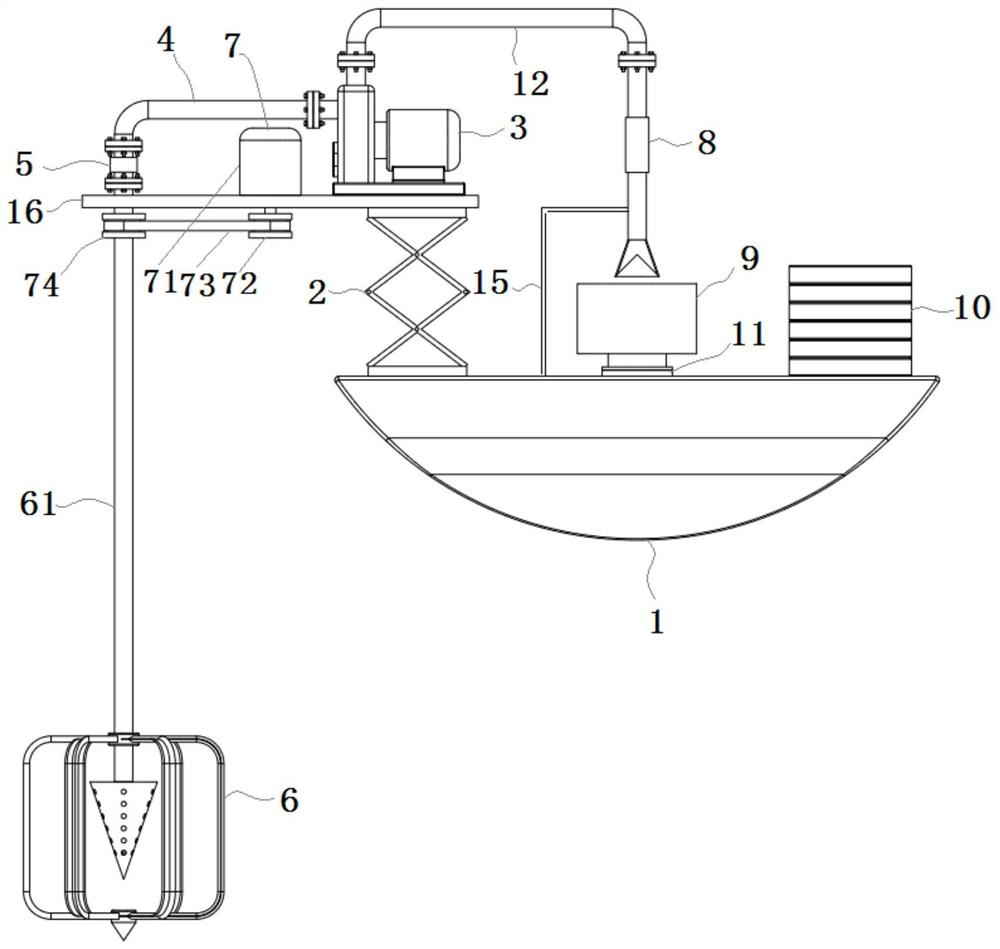

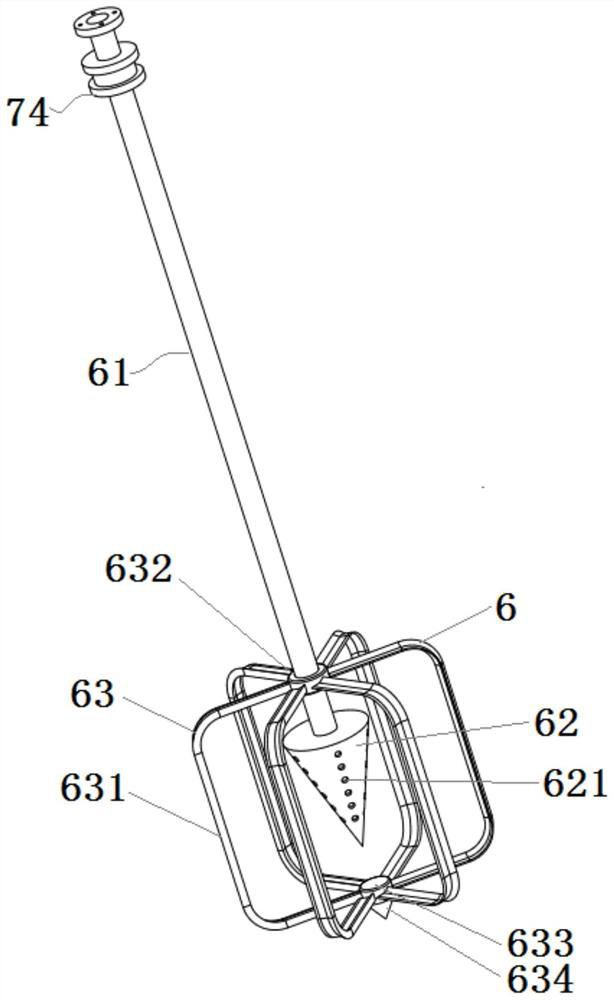

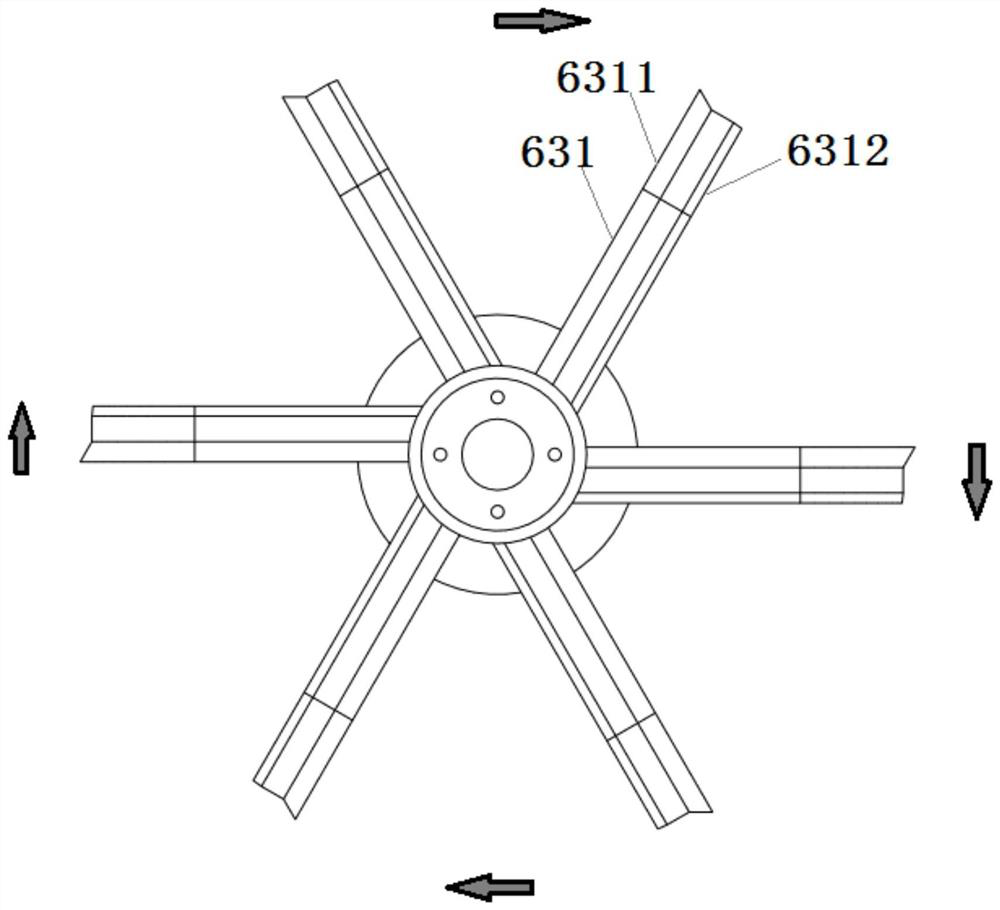

[0037] as attached figure 1 to attach Figure 6 As shown, a sewage suction equipment for cleaning river sludge includes a sewage suction ship 1, an elevator 2 and a sewage suction actuator; The sewage ship 1 has a sludge storage bin, and its bin mouth 11 is provided with a sludge solid impurity screening mechanism 9; The sludge solid impurity screening mechanism 9 removes the mixed solid impurities in the river sludge and stores them in the sludge storage bin; since the river sludge contains solid impurities, such as small stones, the sludge solid impurity screening mechanism 9 is set The solid impurities contained therein can be removed before the river sludge is stored in the sludge storage bin, thereby simplifying the subsequent steps of river sludge treatment.

[0038]The sewage suction execution device includes a sewage suction pump 3, a sludge conveying pipe g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com