Tire structure

A tire and steel structure technology, applied in tire parts, non-pneumatic tires, transportation and packaging, etc., can solve problems such as non-slip, stab-proof, high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

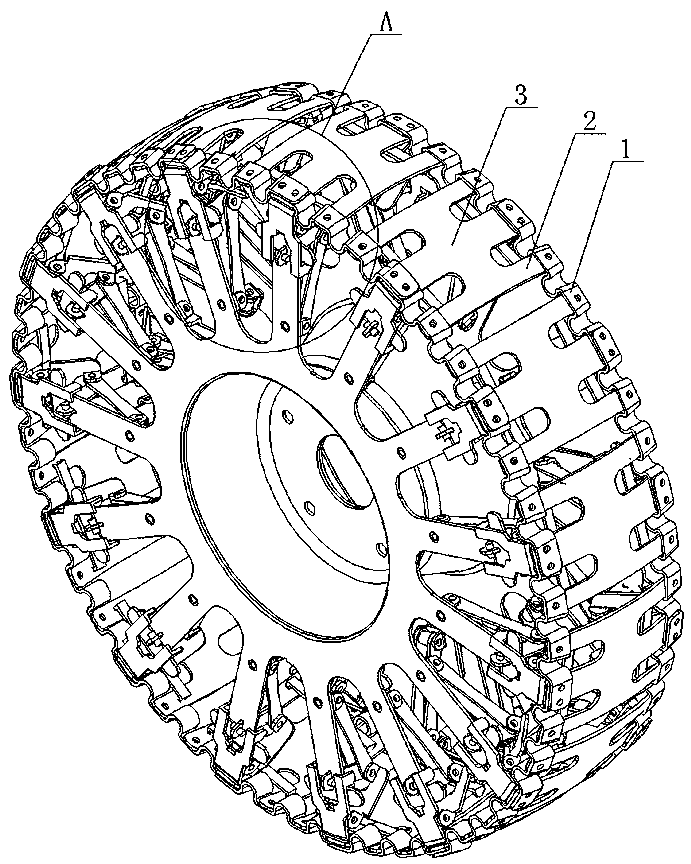

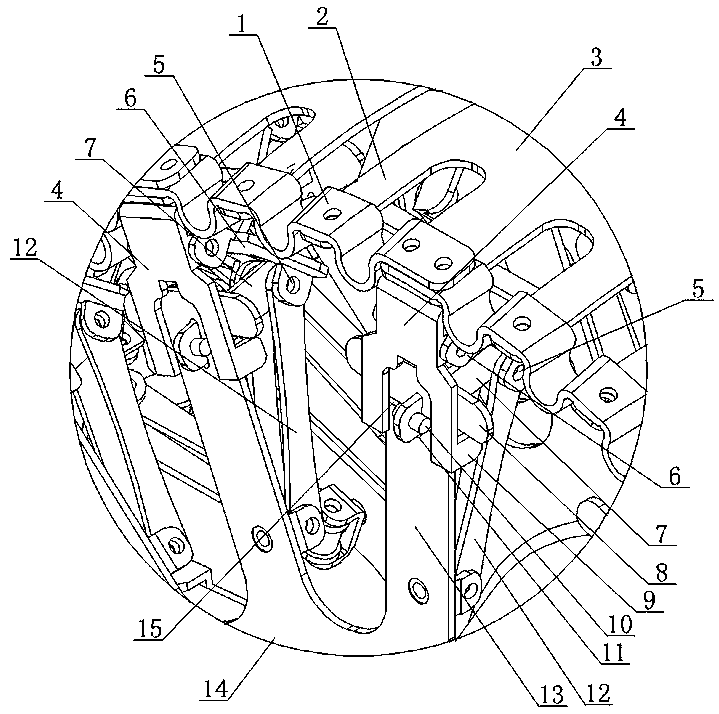

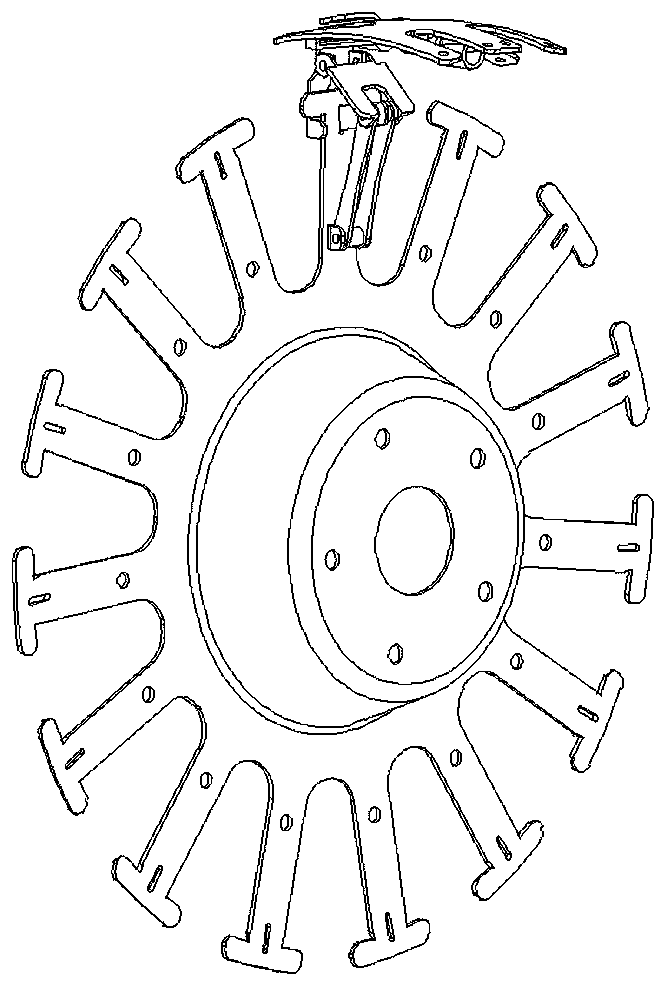

[0021] As shown in the figure, the tire structure of the present invention is composed of fifteen steel structure units arranged around the circumference to form a rolling body that can bear a certain weight. Each steel structure unit includes a cover plate 3, a limit plate 4, a pulley Plate 7, upper hinge plate 6 and lower hinge plate 12, cover plate 3, limit plate 4, pull plate 7, upper hinge plate 6 and lower hinge plate 12 are spring steel stamping parts, and the cover plates of adjacent steel structure units 3 are fixedly connected by elastic bending plates 1, and the two sides of each cover plate 3 are extended outward with three elastic slats 2, and the adjacent elastic slats 2 are connected by elastic bending plates 1, and the elastic bending plates 1 is a spring steel stamping with U-shaped bending. The limiting plate 4 is fixed on both sides of the cover plate 3, and the limiting plate 4 can be radially moved on the central disk 14. The outer circle of the central di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com