Reflux closed-circuit and open-circuit dual-purpose wind tunnel

A closed-circuit, wind tunnel technology, applied in measurement devices, instruments, aerodynamic tests, etc., can solve problems such as complex structure, inability to use wind tunnels for large-scale engineering applications, and difficult operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

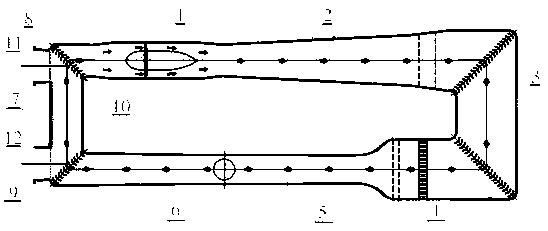

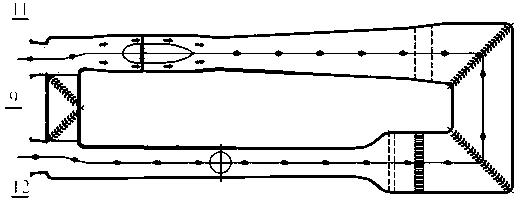

[0028] Such as figure 1 and figure 2 As shown, the dual-purpose layer wind tunnel of the present invention's backflow closed circuit and open circuit mainly includes a power and fan section 1, a first diffusion section 2, a first return section 3, a stabilization and contraction section 4, a test section 5, and a second diffusion section 6 , the second backflow section 7. An air inlet 8 and an air intake valve 11 are arranged upstream of the power and fan section 1 , and an air outlet 9 and an exhaust valve 12 are arranged downstream of the second diffuser section 6 . The power section and the fan section, the first diffusion section, the first return section, the stabilization and contraction section, the test section, the second diffusion section and the second return section can adopt all-steel structures.

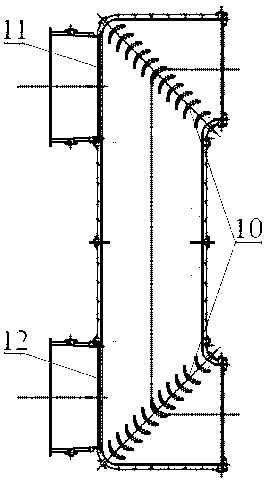

[0029] Deflector units are provided at the connecting corners on both sides of the first recirculation section, and guide vane units are provided at the connecting c...

Embodiment 2

[0034] In this embodiment, it is further designed as a dual-purpose wind tunnel with open and closed circuit of return flow, and the valves at both ends of the second return section are installed on the outer wall of the second return section, and can rotate around the axis to realize inward and outward opening and closing.

Embodiment 3

[0036] In this embodiment, it is further designed that a pair of linear rolling guide rails is provided at the bottom of the deflector unit at the two corners of the second recirculation section, and the guide vane unit is translated to the inside of the second recirculation section through the pair of linear rolling guide rails.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com