Washer for a composite material, system of a washer and a composite material, and method for producing a construction

A technology of composite materials and gaskets, applied in the direction of gaskets, connecting components, thin plate connections, etc., can solve problems such as loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the different figures, identical components are always marked with the same reference numerals and are therefore generally only named or mentioned once in each case.

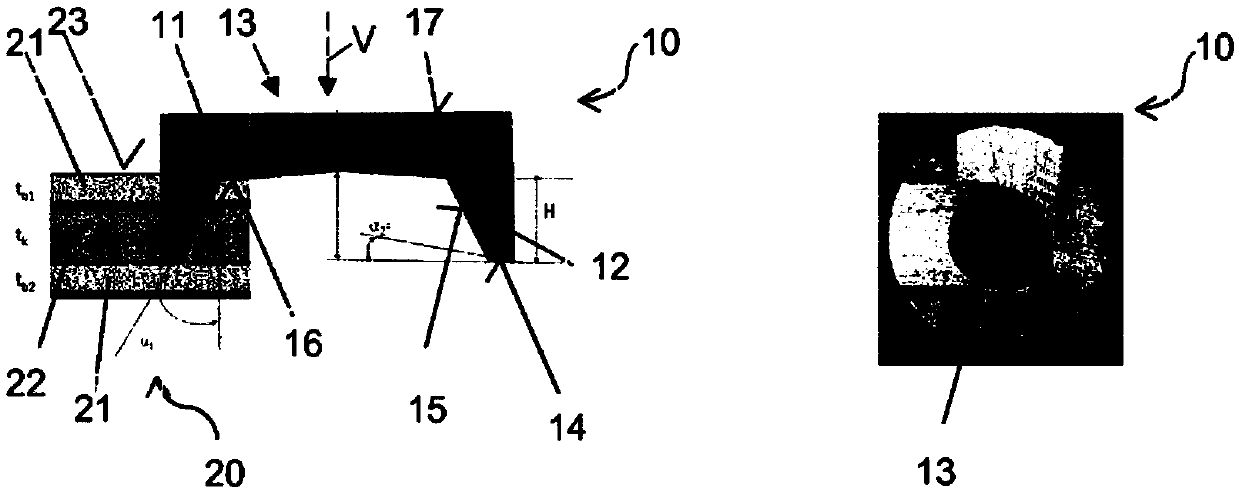

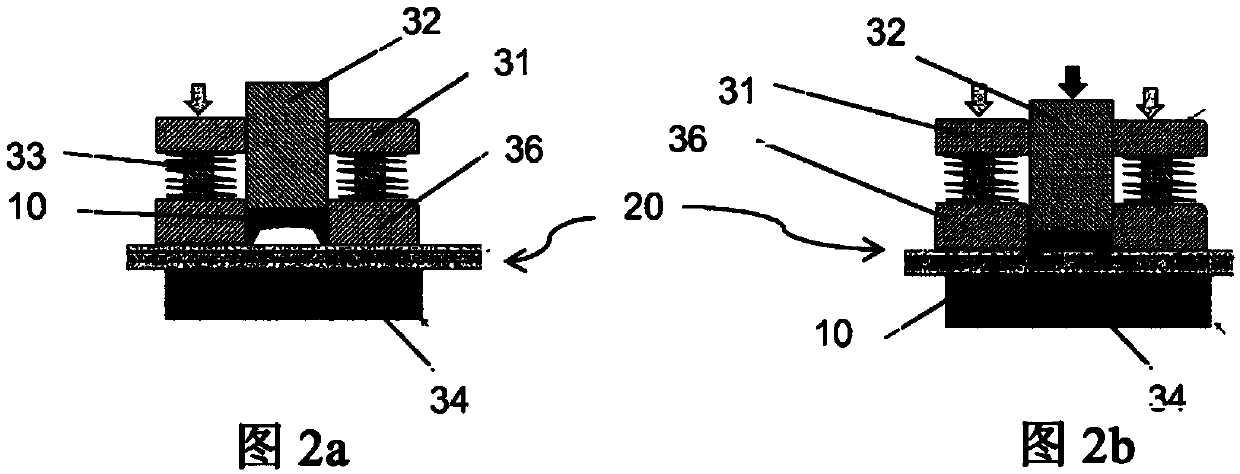

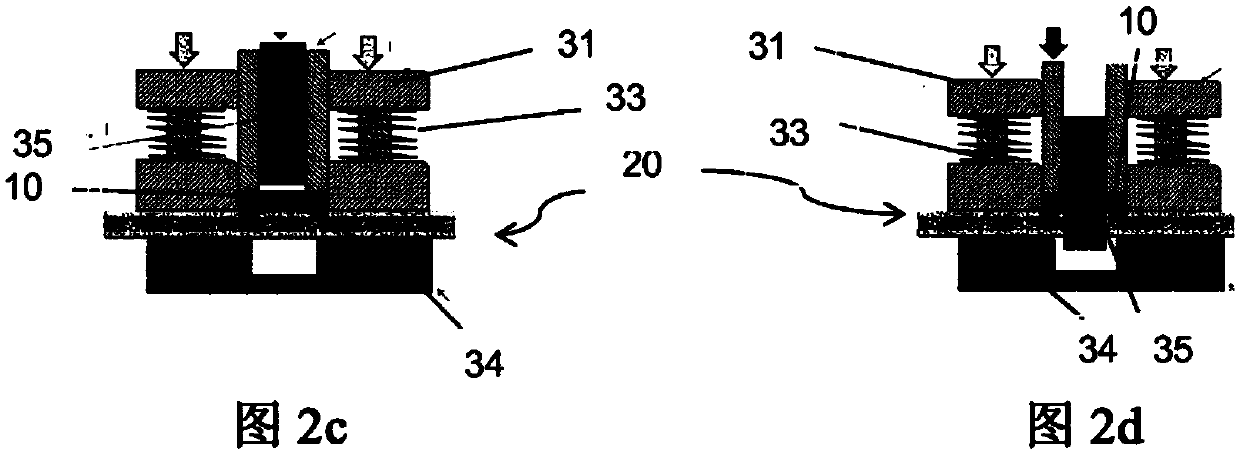

[0031] exist figure 1 A sectional view (left) and a bottom view (right) of a gasket 10 according to an exemplary embodiment of the invention are shown. The gasket 10 is provided in particular to facilitate the connection of a composite material 20 , for example having two metallic cover layers 21 and a non-metallic core layer 22 arranged between the metallic cover layers 21 , to a component 40 or other composite workpiece. For this purpose, the gasket 10 comprises a base body 11 , in particular a disk-shaped base body 11 , which has a recess 13 for receiving a connecting element, which protrudes through the recess 13 in the connecting direction V during the connection. The connecting elements are, for example, bolts 42 . The base body 11 preferably forms a closed ring, in particular an annular disk. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com