A diaphragm type linear motor

A linear motor and diaphragm type technology, applied in the field of diaphragm type linear motors, can solve the problems of small shrapnel damping, long stop time, and large vibration sense changes, and achieve the effect of reducing stop time and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

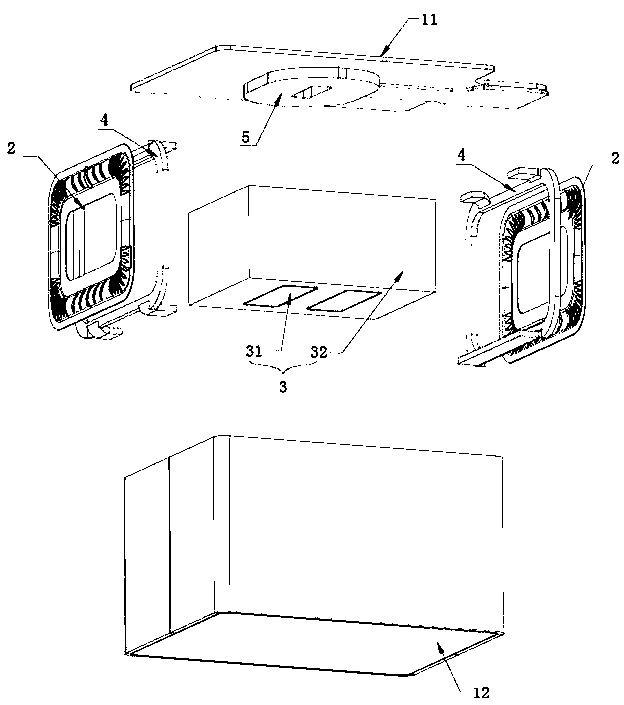

Embodiment 1

[0044] For the diaphragm type linear motor in Embodiment 1, the power drive structure includes the third magnet on the vibrator 3 and the second coil 5 located on the upper cover 11. The vibration intensity of the diaphragm type linear motor is small, and it is often necessary to use multiple diaphragms A linear motor is used to drive the target.

[0045] Different from the first embodiment, this embodiment also improves the power driving structure of the diaphragm type linear motor.

[0046] Such as Figure 6As shown, in this embodiment, the vibrator 3 includes a permanent magnet and a fixing block 6 for fixing the permanent magnet. The permanent magnets include a first permanent magnet 81 and a second permanent magnet 82 . On the vibrator 3 , the magnetic poles of the first permanent magnet 81 and the second permanent magnet 82 are oppositely arranged.

[0047] The electromagnet 7 includes an iron core 71 and a first coil 72 wound on the iron core 71 , and an alternating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com