Squeezing rod and camellia oleifera fruit squeezing equipment for improving oil extraction rate

A technology of pressing rods and oil yield rate, which is applied in the direction of presses, oil/fat production, fat production, etc. It can solve the problems of shortening the fine pressing time, affecting the service life of pressing equipment, and insufficient and incomplete pressing, so as to extend the pressing Effect of working time, shortening transition pressing time, and shortening transition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

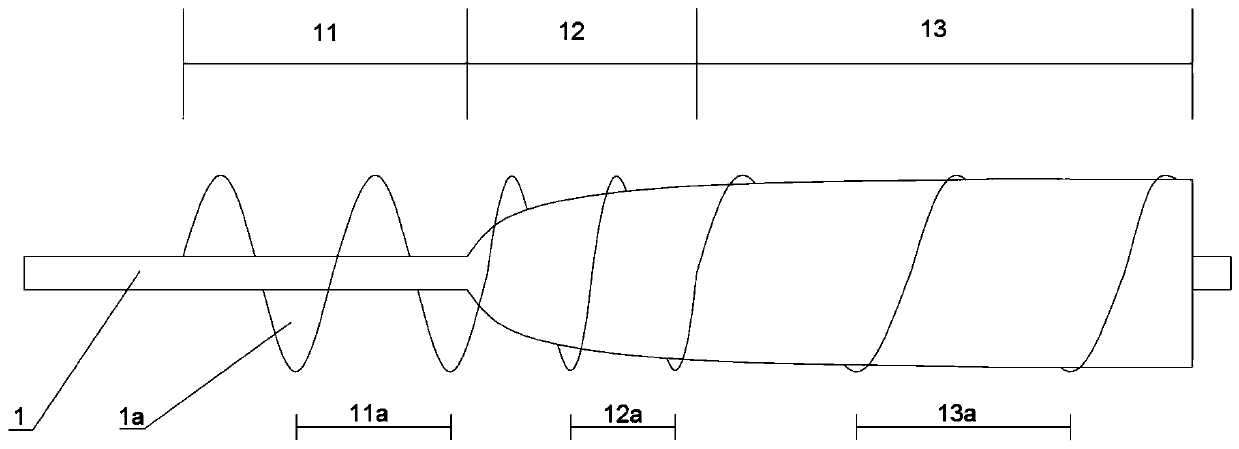

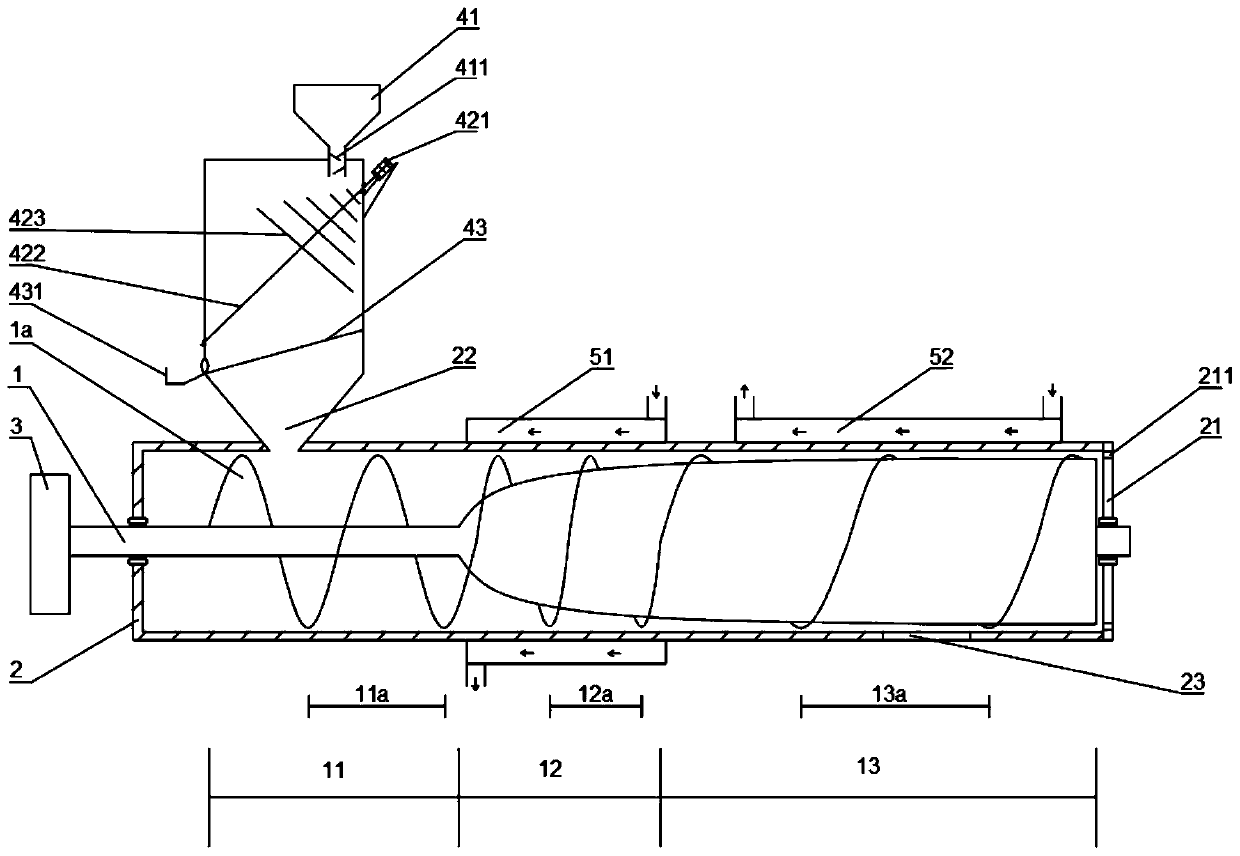

[0026] Please refer to figure 1 , a press rod for increasing oil yield in this embodiment, comprising a rod body 1 and a screw blade 1a fixed and continuous surrounding the rod body 1, and the rod body 1 is sequentially provided with a feed section 11, Initial pressure section 12 and fine pressure section 13. The diameter of the rod body 1 in the feed section 11 is equal in this embodiment, and may not be equal in other embodiments. The feeding section 11 is mainly used for conveying materials, which acts as a link between the preceding and the following, and then sends the materials into the initial pressing section 12; the initial pressing section 12 is mainly used to reduce the pressing space and play a transitional role. The structure of this embodiment can make the transition The stage ends quickly, saving time and improving efficiency; the initi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com