Upper grinding mechanism with dynamic grinding function

A functional and dynamic technology, applied in the direction of grinding tools, grinding machine parts, grinding drive devices, etc., can solve problems such as uneven grinding, achieve the effect of improving grinding effect, preventing excessive concentration, and improving grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

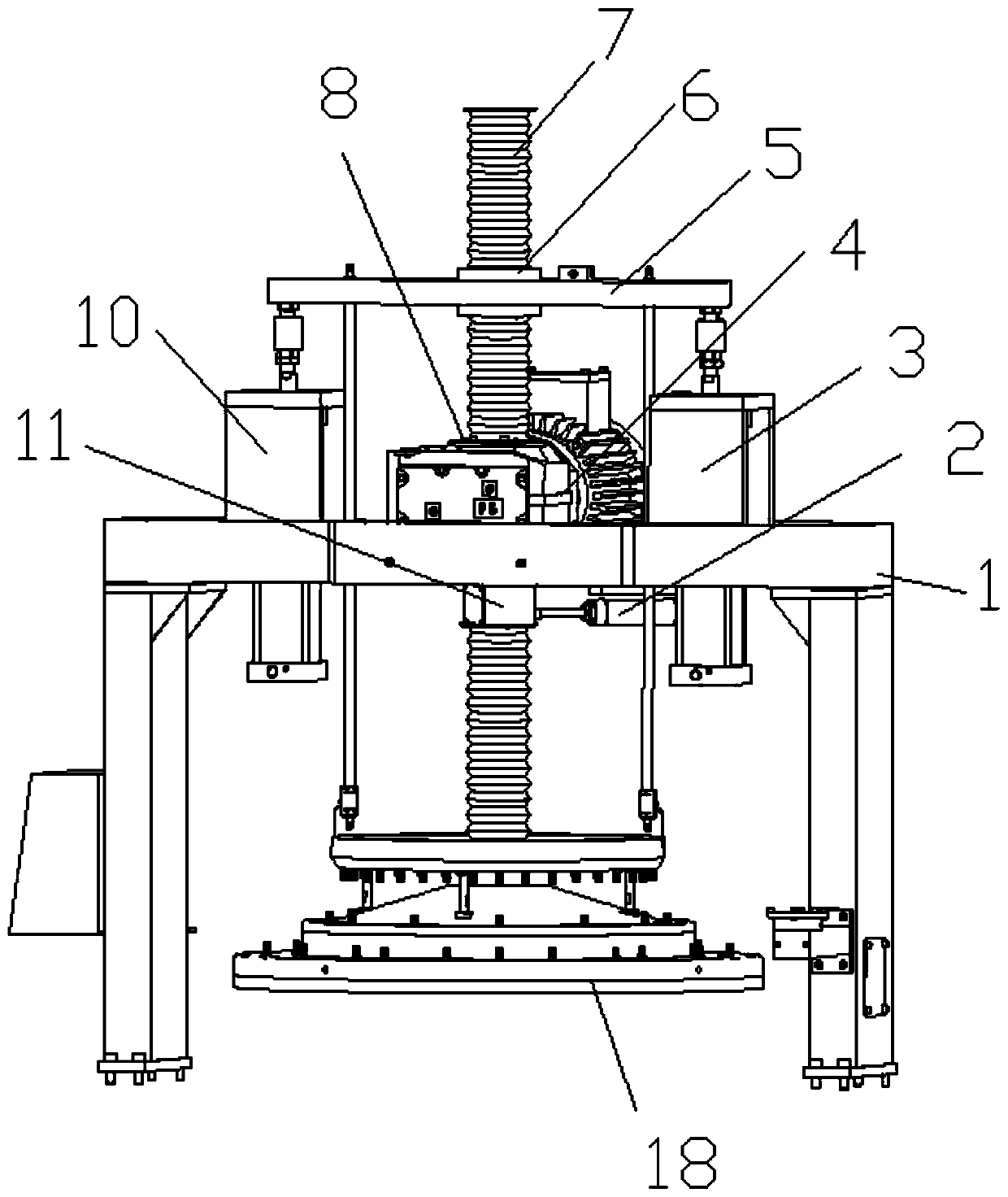

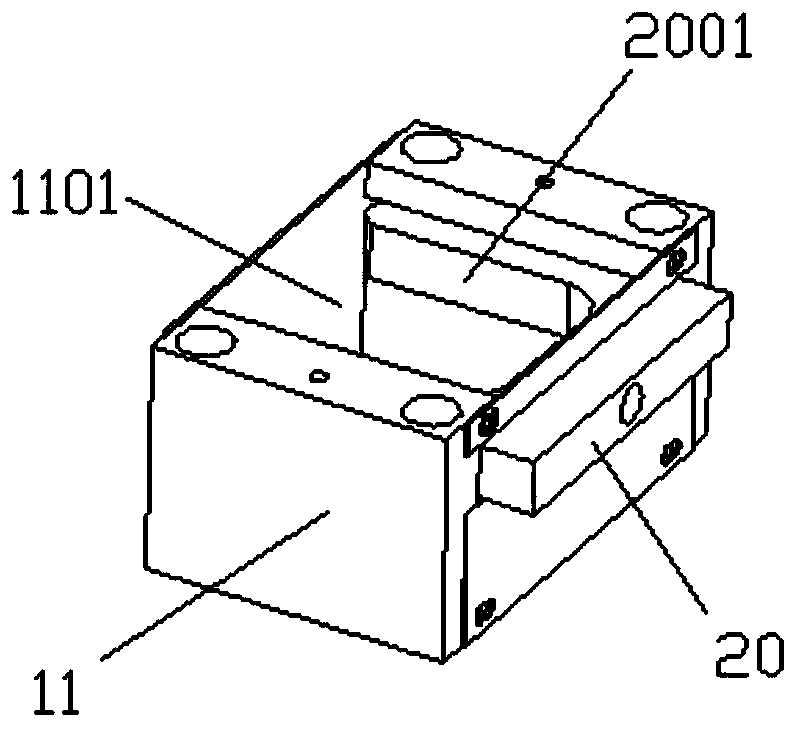

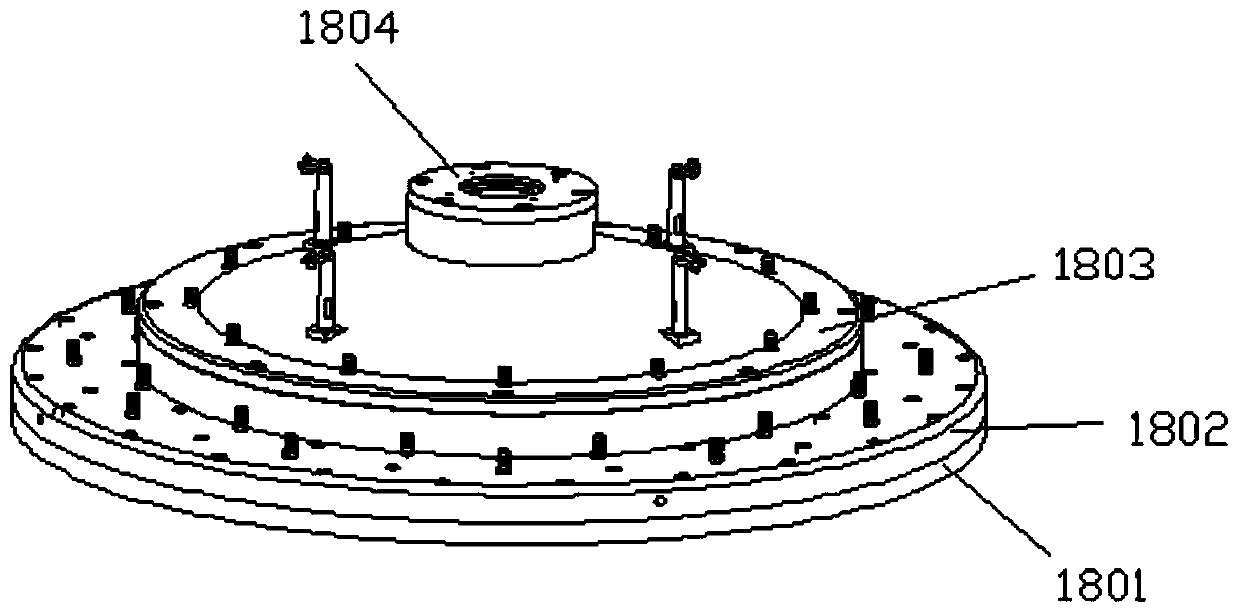

[0018] Such as Figure 1-Figure 3 As shown, the concrete structure of the present invention is: it comprises support frame 1, reduction motor 4, rotating shaft 7 and upper grinding body 18, reduction motor 4 is fixed on the support frame 1, and rotation shaft 7 is vertically installed on reduction motor 4 output On the first eccentric bearing 8 at the end, the upper grinding body 18 is fixed on the bottom of the rotating shaft 7; the upper end of the rotating shaft 7 is fixedly connected with the second eccentric bearing 6, and the second eccentric bearing 6 is connected with the middle part of the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com