Pressure vessel steel sheet having excellent pwht resistance, and manufacturing method therefor

A technology for pressure vessels and steel plates, which is applied in the field of pressure vessel steel plates and its manufacturing, and can solve the problems of steel plate tensile strength deterioration, steel plate tensile strength and impact toughness deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

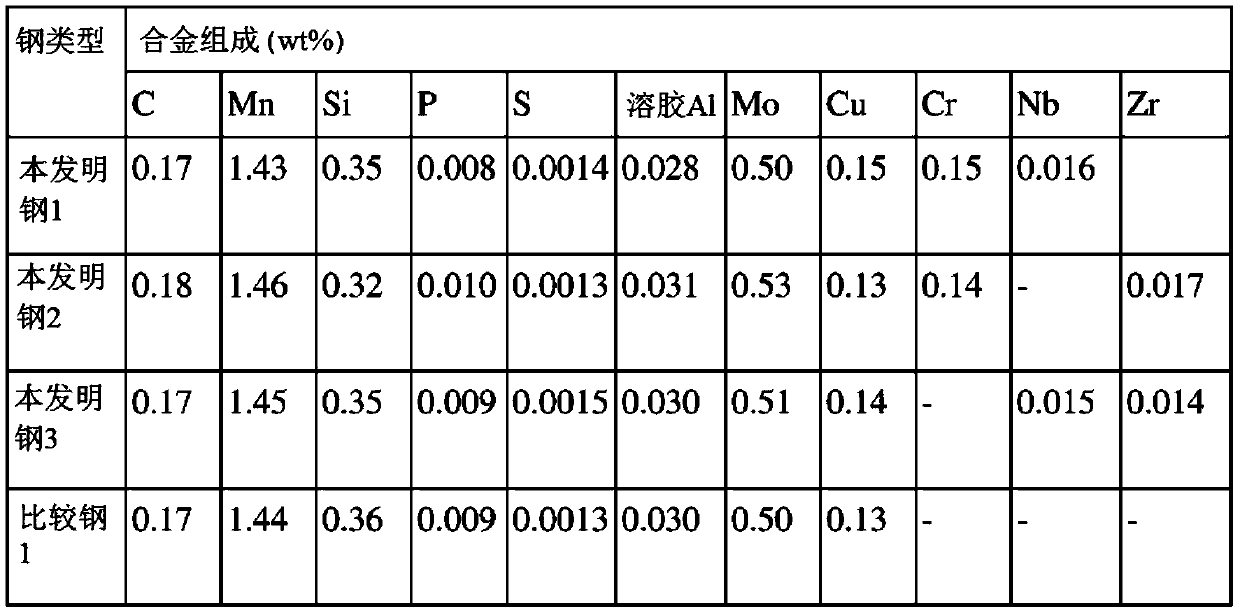

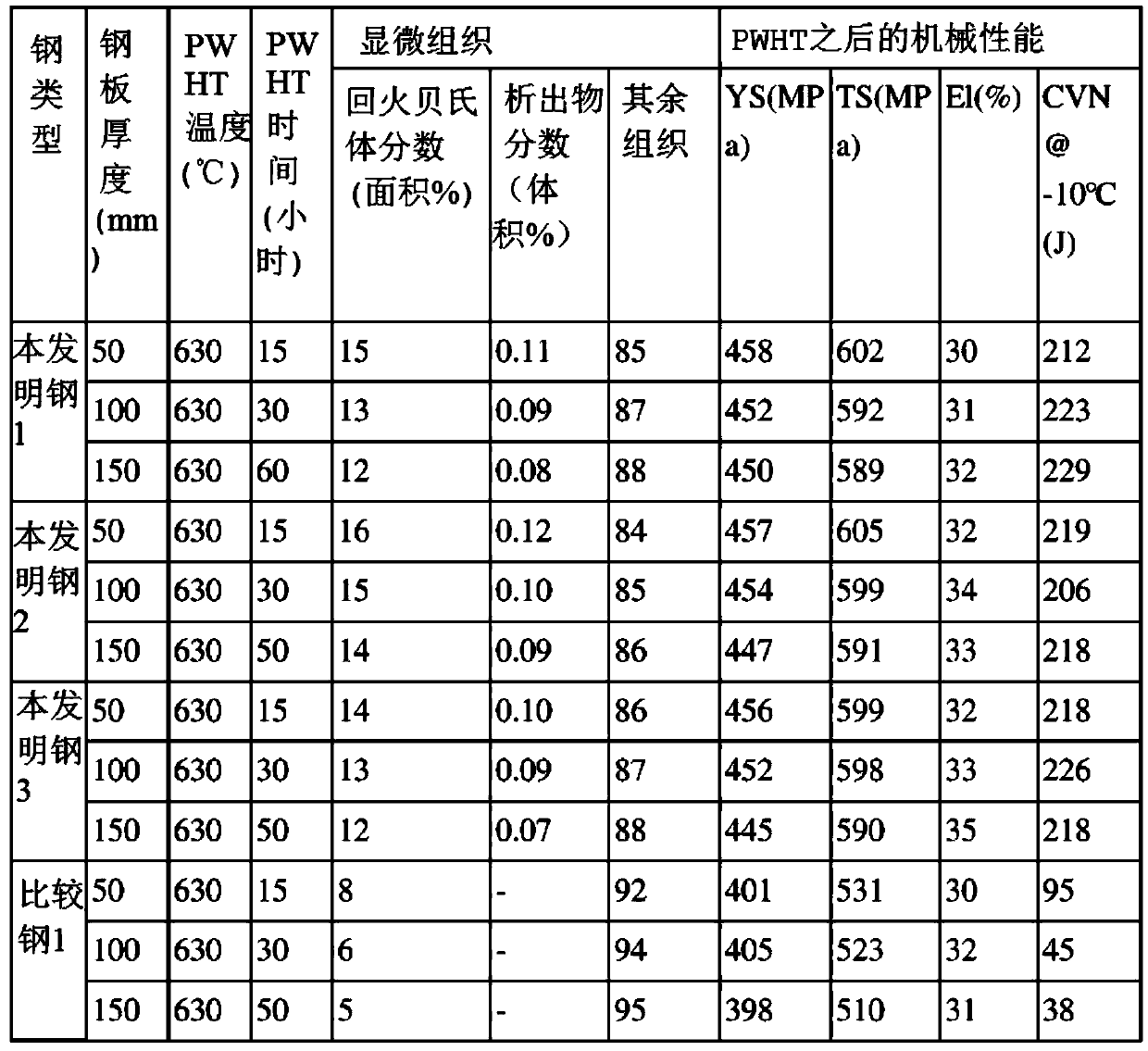

[0055] The slabs having the composition shown in Table 1 below were reheated for 300 minutes at 1140°C, and in the recrystallization zone (1100°C to 900°C) at a reduction rate of 10% to 15% per pass The hot-rolling process is completed in the process to obtain hot-rolled steel sheets. Thereafter, the hot-rolled steel plate was subjected to a normalizing heat treatment of 1.3×t+20 minutes at 890° C., cooled in the air, and the cooled steel sheet was subjected to a return temperature of 1.6×t+20 minutes at 650° C. Fire heat treatment to obtain pressure vessel steel plate.

[0056] The PWHT process was performed under the conditions for the pressure vessel listed in Table 2 below, the microstructure was analyzed, and yield strength, tensile strength, elongation, and low temperature impact toughness were measured and listed in Table 2. For all the examples in Table 2, the rest of the structure except tempered bainite is ferrite and pearlite, and the precipitate volume can refer t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com