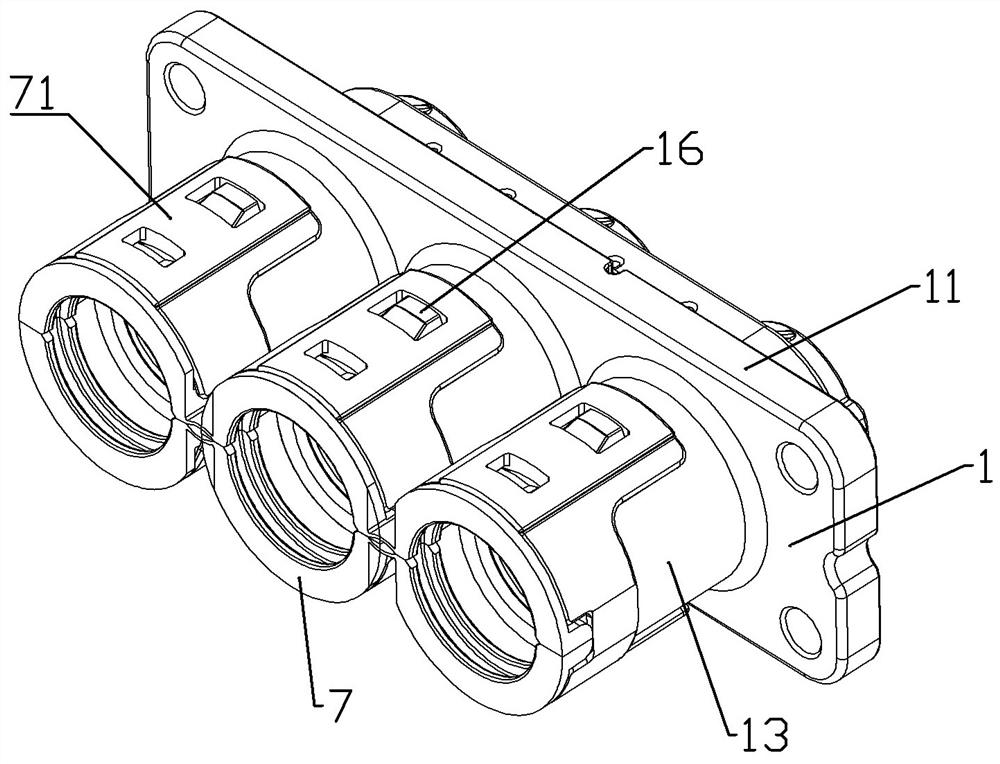

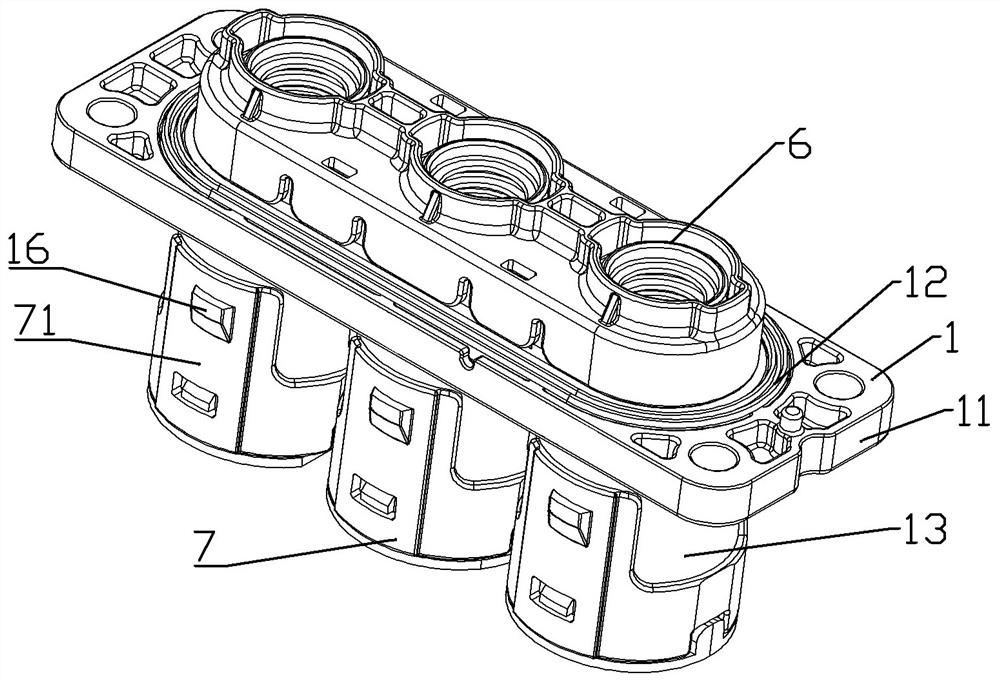

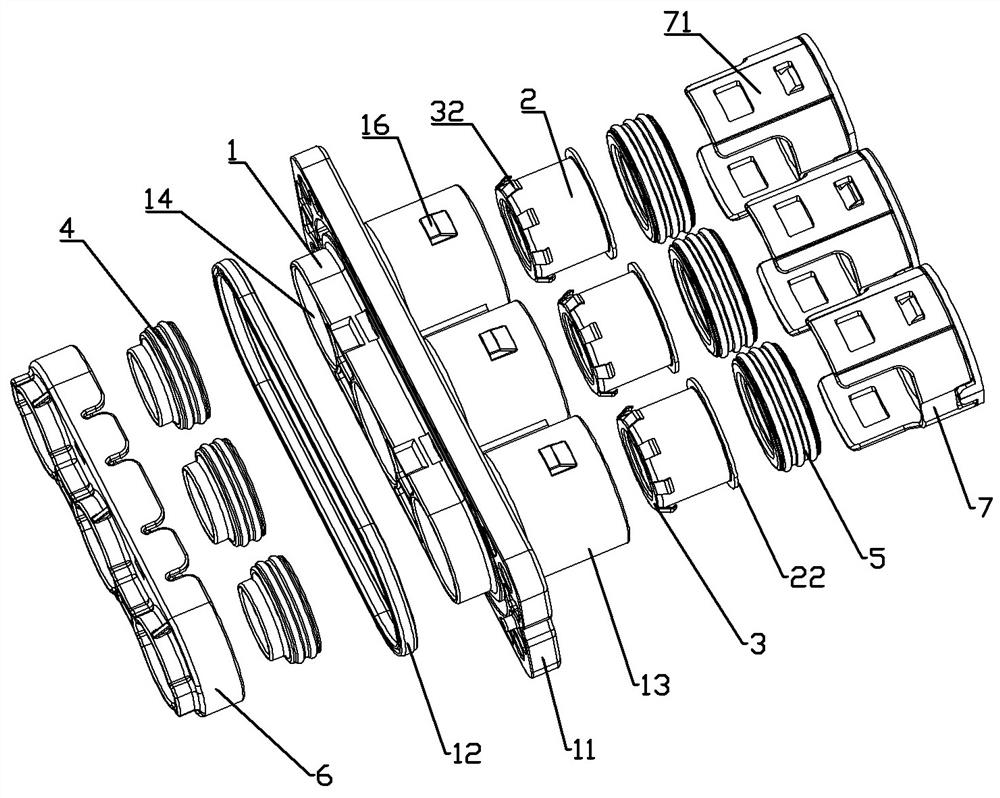

Connector and its shielding sleeve assembly

A technology for shielding sleeves and connectors, which is applied to parts, connections, and electrical components of connecting devices, and can solve the problems of occupying the axial space of high-voltage through-hole connectors and increasing the axial size of the connectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0036] Embodiment 2 of the connector of the present invention differs from Embodiment 1 in that: in Embodiment 1, the shielding ring is fixedly assembled with the shielding sleeve separately through the annular body. In this embodiment, the annular body of the shielding ring is welded to the shielding sleeve superior.

Embodiment 3

[0037] Embodiment 3 of the connector of the present invention differs from Embodiment 1 in that: in Embodiment 1, the annular body is separately fixed and assembled with the inversion edge of the shielding sleeve through the flanging. In this embodiment, the inversion of the shielding sleeve A slot is provided on the inner peripheral surface of the ring, and a protrusion protruding radially is provided on the annular body, and the protrusion cooperates with the slot to make the shielding ring and the shielding sleeve separately and fixedly assembled.

[0038] Embodiment 4 of the connector of the present invention differs from Embodiment 1 in that: in Embodiment 1, the rear end of the shielding sleeve is provided with an eversion edge, and the rear sealing ring cooperates with the eversion edge. In this embodiment , the valgus edge of the shielding sleeve is omitted, the rear end of the shielding sleeve has a thickened portion with an increased radial thickness, and the rear sid...

Embodiment 5

[0039] Embodiment 5 of the connector of the present invention differs from Embodiment 1 in that: in Embodiment 1, the rear end of the shrapnel is bent toward the shielding sleeve, and the middle part of the shrapnel forms an arc-shaped pressing portion. In this embodiment, the shrapnel The rear end is provided with a circular protrusion extending radially along the shielding sleeve, and the shrapnel is elastically press-fitted with the metal shell through the circular protrusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com