Electric connector

A technology of electrical connectors and grounding parts, applied in the field of electrical connectors with good high-frequency performance, can solve the problems that the mechanical properties of terminals cannot be guaranteed, the mechanical properties of contact arms are easily damaged, and cross talk, so as to avoid the formation of interfering electromagnetic waves. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

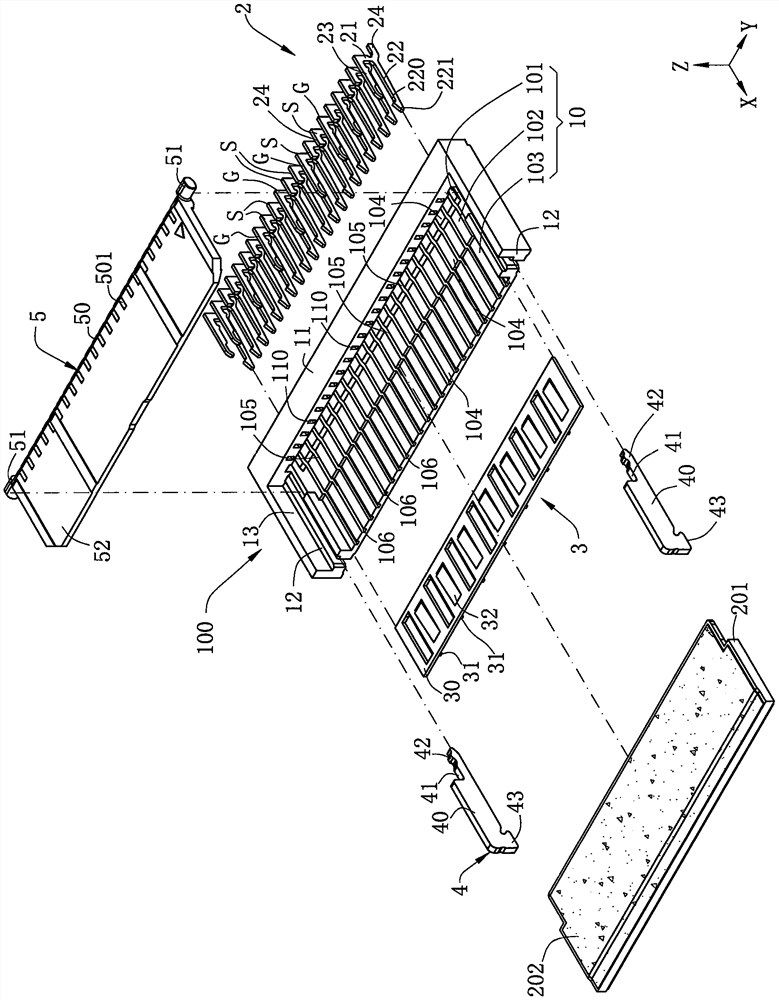

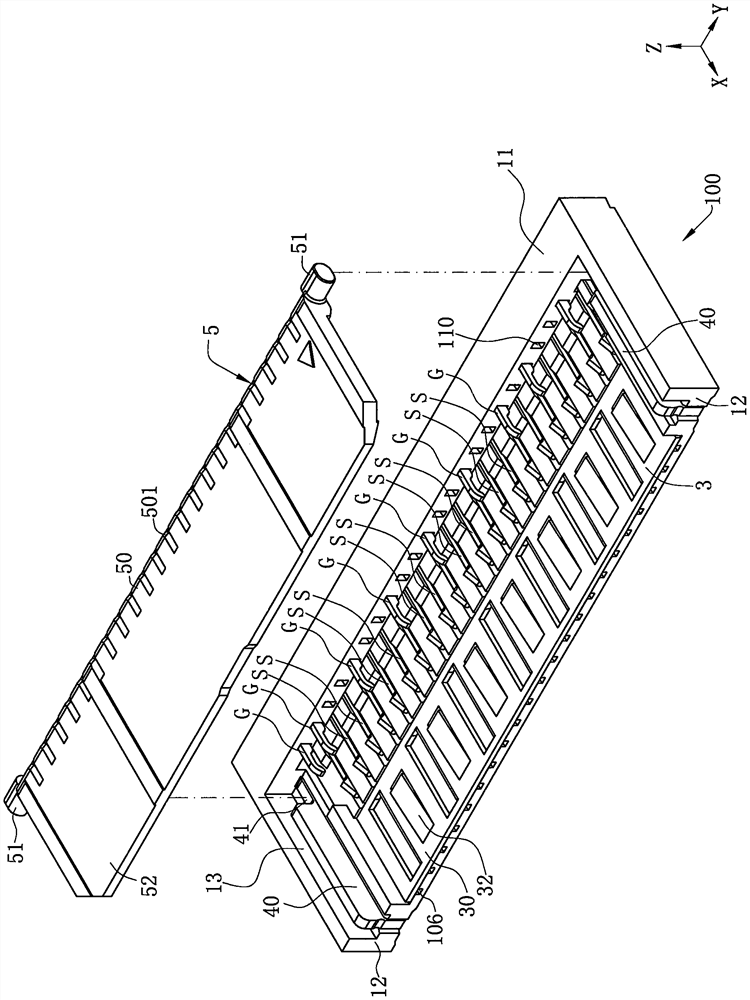

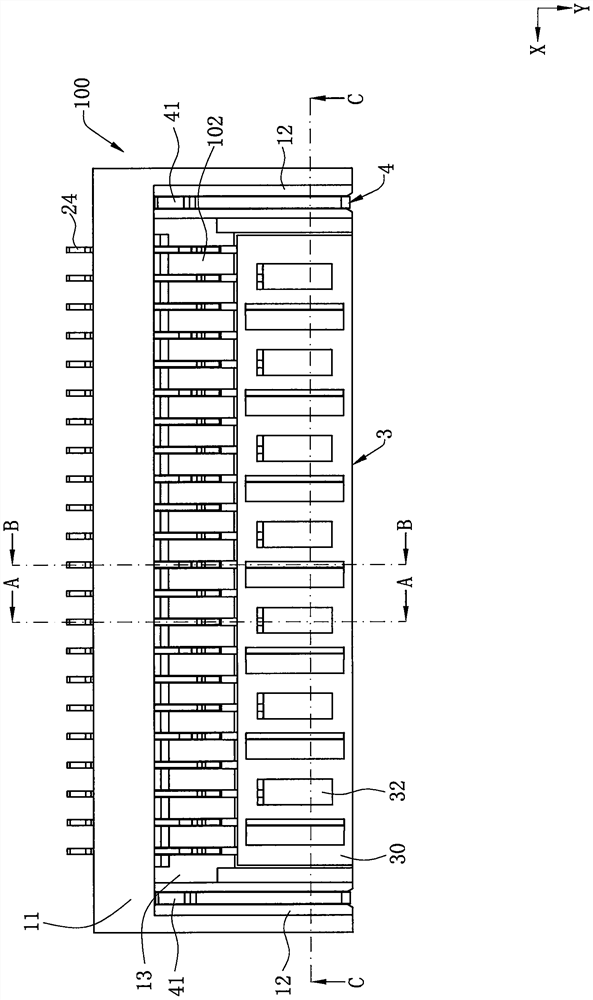

[0042] see figure 1 , figure 2 with Figure 4 , this is an electrical connector 100 according to the first embodiment of the present invention, which is used to electrically connect a first electrical component 200 and a second electrical component (not shown), and the electrical connector 100 has a An insulating body 1, a row of terminals 2 arranged in left and right rows are fixed on the insulating body 1 and connected upward to the first electrical element 200, a grounding member 3 is arranged in front of a row of the terminals 2, Two metal locking parts 4 are fixed on the left and right ends of the insulating body 1 and are located on both sides of a row of terminals 2, and a conductive cover 5 is pivotally connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com