Combustion systems and boilers

A technology of combustion system and fuel system, applied in the direction of combustion type, combustion equipment, combustion method, etc., can solve the problems of severe pollution, low fuel efficiency of oil-fired boilers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

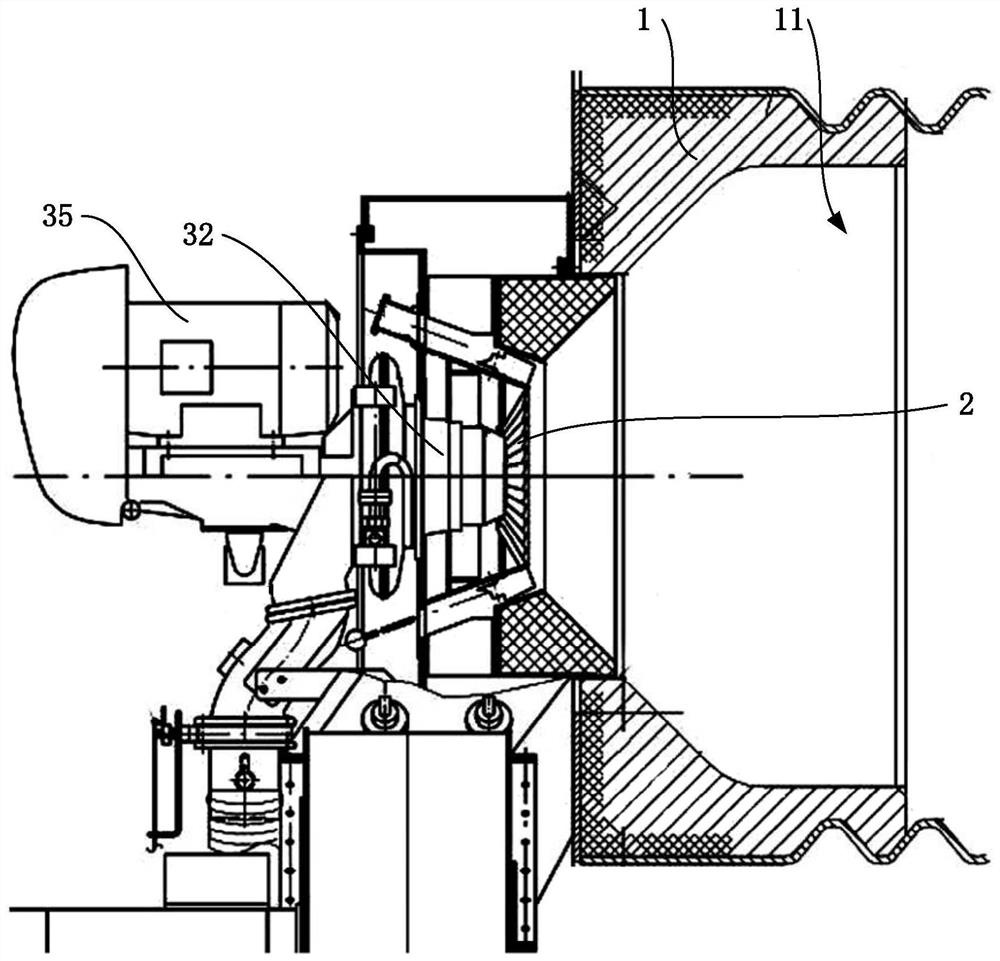

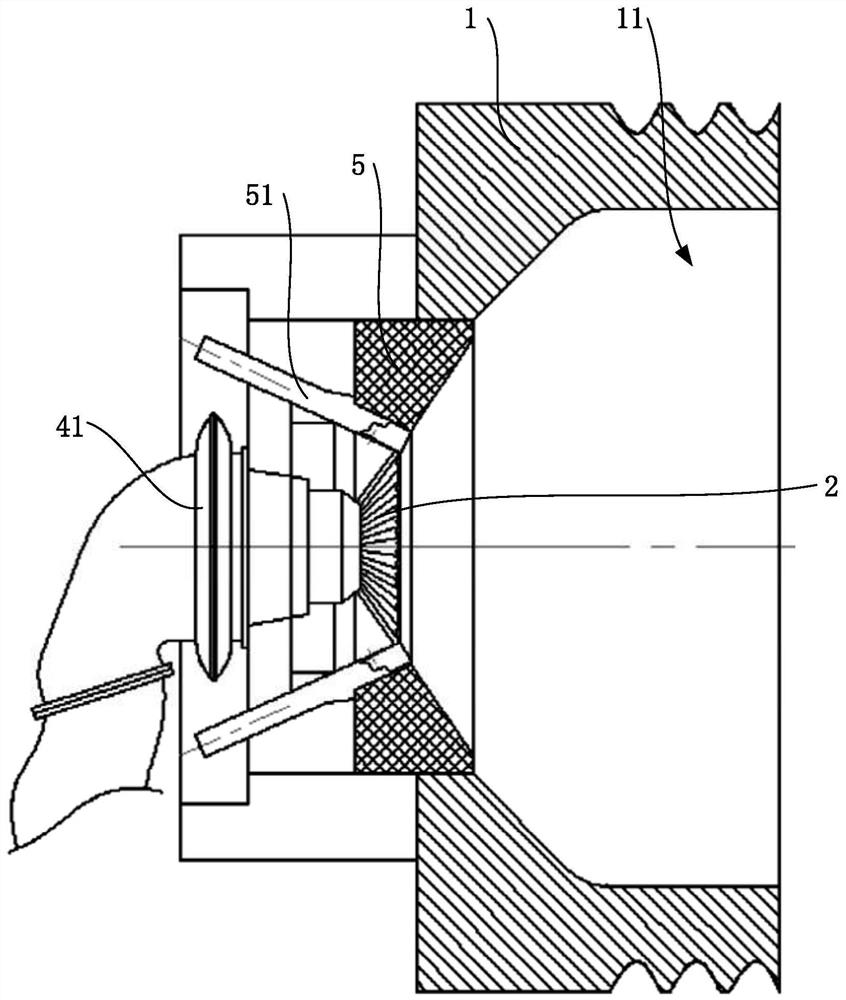

[0037] Combine below Figure 1 to Figure 6 The technical solution provided by the present invention is described in more detail.

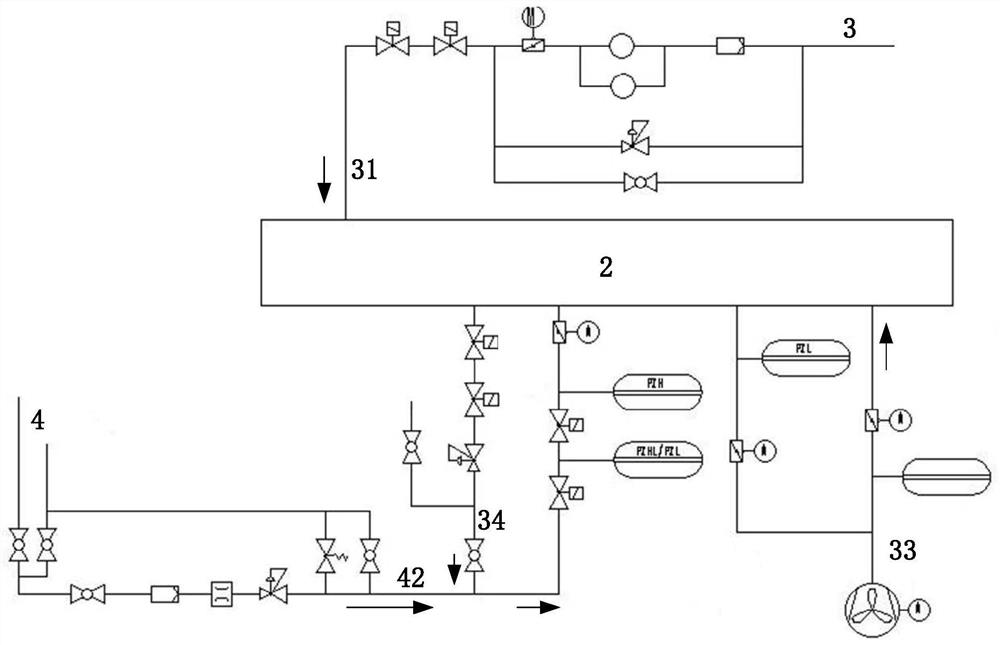

[0038] see Figure 1 to Figure 3 , the embodiment of the present invention provides a combustion system, including a furnace 1 , a burner 2 , a first fuel system 3 and a second fuel system 4 .

[0039] The combustion system mainly includes a burner 2, a fuel system, and an air supply system. The fuel system is used to provide the fuel required by the burner 2 . There are two types of fuels: gaseous fuels and oily liquid fuels. The first fuel system 3 is used to supply fuel oil to the burner 2 . The second fuel system 4 is used to provide gas fuel to the burner 2, such as natural gas, liquefied petroleum gas and the like. The air supply system mainly refers to providing the main air required for combustion. In the field of combustion systems, it is also called secondary air. The various embodiments of the present invention do not relate to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com