a building window film

A window film and architectural technology, applied in the direction of film/sheet release coating, film/sheet adhesive, coating, etc., can solve the problems of high cost, complicated manufacturing process, interference of mobile phone signals, etc., to achieve The effect of low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

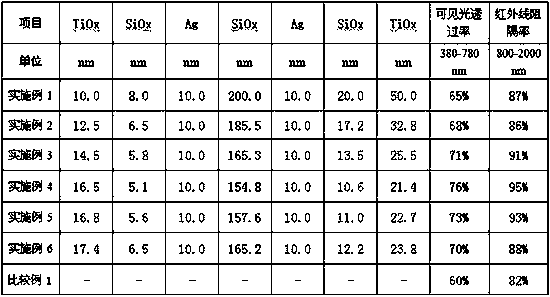

Embodiment 1

[0022] One side of the polyester film substrate is hardened, and nano-Ag, TiO2, and SiO2 are respectively added to water-soluble polyester resin W-0030 (NIPPON GOHSEI), and dispersed evenly by a high-shear emulsifier to make coatings with different optical refractive index constants. Liquid distribution, on the other side of the hardened layer, the thickness of 7 layers is completed at one time by means of multi-layer slide extrusion coating: TiO2 (10.0nm) / SiO2 (8.0nm) / Ag (10.0nm) / SiO2 (200.0nm) / Ag(10.0nm) / SiO2(20.0nm) / TiO2(50.0nm), install adhesive layer coating on several thin film coatings with different optical refractive indices, composite PET release film, detection of visible light 380nm- 780nm light transmittance, infrared 800nm-2000nm reflection rejection rate. (See Table 1).

Embodiment 2

[0024] One side of the polyester film substrate is hardened, and nano-Ag, TiO2, and SiO2 are respectively added to water-soluble polyester resin W-0030 (NIPPON GOHSEI), and dispersed evenly by a high-shear emulsifier to make coatings with different optical refractive index constants. Liquid distribution, on the other side of the hardened layer, the thickness of 7 layers is completed at one time by multi-layer slide extrusion coating: TiO2(12.5nm) / SiO2(6.5nm) / Ag(10.0nm) / SiO2(185.5nm) / Ag(10.0nm) / SiO2(17.2nm) / TiO2(32.8nm), install adhesive layer coating on several thin film coatings with different optical refractive index, composite PET release film, detect visible light 380nm- 780nm light transmittance, infrared 800nm-2000nm reflection rejection rate. (See Table 1).

Embodiment 3

[0026] One side of the polyester film substrate is hardened, and nano-Ag, TiO2, and SiO2 are respectively added to water-soluble polyester resin W-0030 (NIPPON GOHSEI), and dispersed evenly by a high-shear emulsifier to make coatings with different optical refractive index constants. Liquid distribution, on the other side of the hardened layer, the thickness of 7 layers is completed at one time by multi-layer slide extrusion coating: TiO2(14.5nm) / SiO2(5.8nm) / Ag(10.0nm) / SiO2(165.3nm) / Ag(10.0nm) / SiO2(13.5nm) / TiO2(25.5nm), install adhesive layer coating on several thin film coatings with different optical refractive indices, composite PET release film, detect visible light 380nm- 780nm light transmittance, infrared 800nm-2000nm reflection rejection rate. (See Table 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com