Locking structure for connecting material frame with trailer

A technology of locking structure and material rack, which is used in traction connectors, vehicle parts, transportation and packaging, etc., to reduce the labor intensity of employees, improve production efficiency, and make employees operate efficiently, accurately and quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is attached with the manual Figure 1-4 The specific embodiment of the present invention is further described:

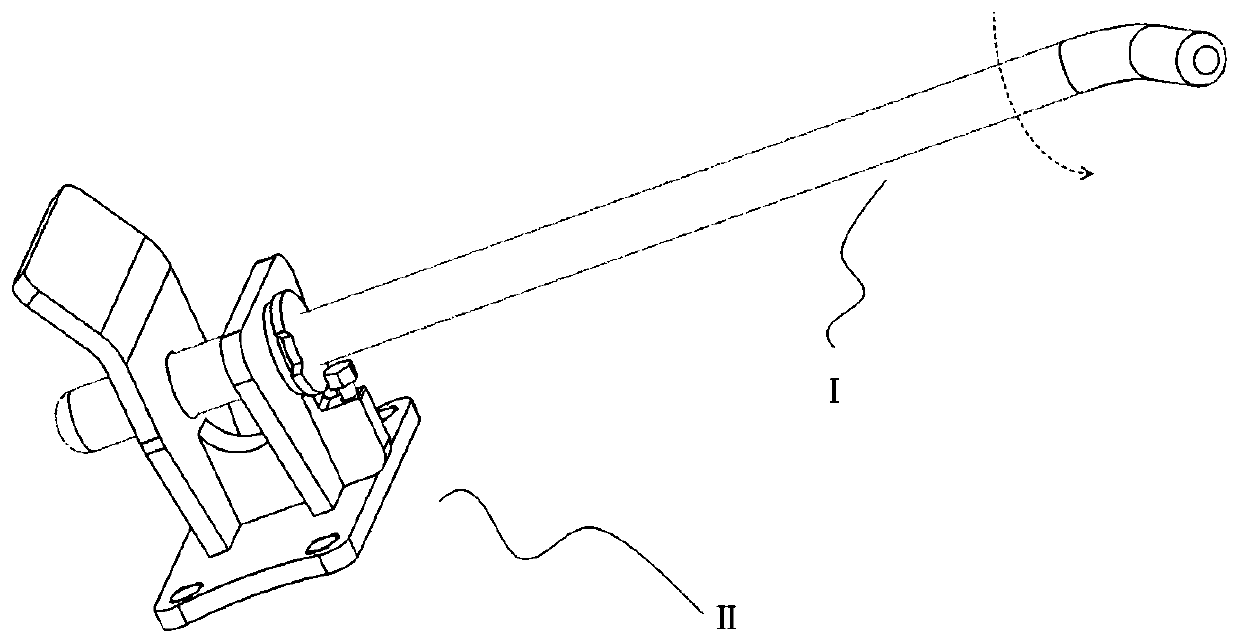

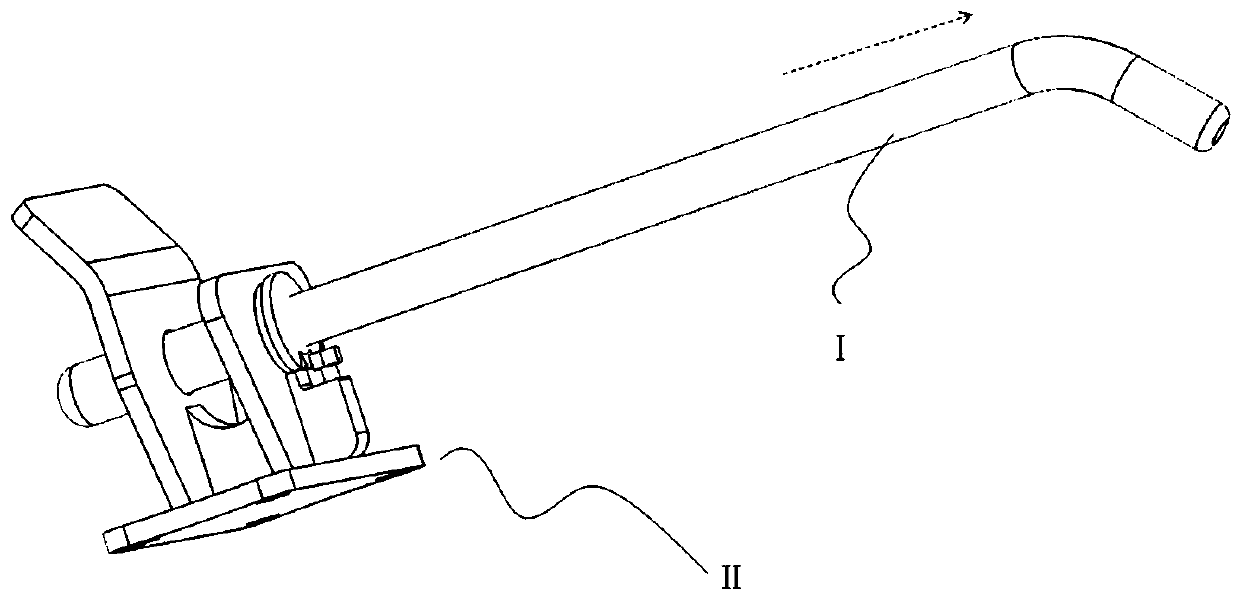

[0022] Such as Figure 1-2 Shown: a locking structure connecting the material rack and the trailer, the locking structure is composed of a movable rod Ⅰ and a mounting seat Ⅱ;

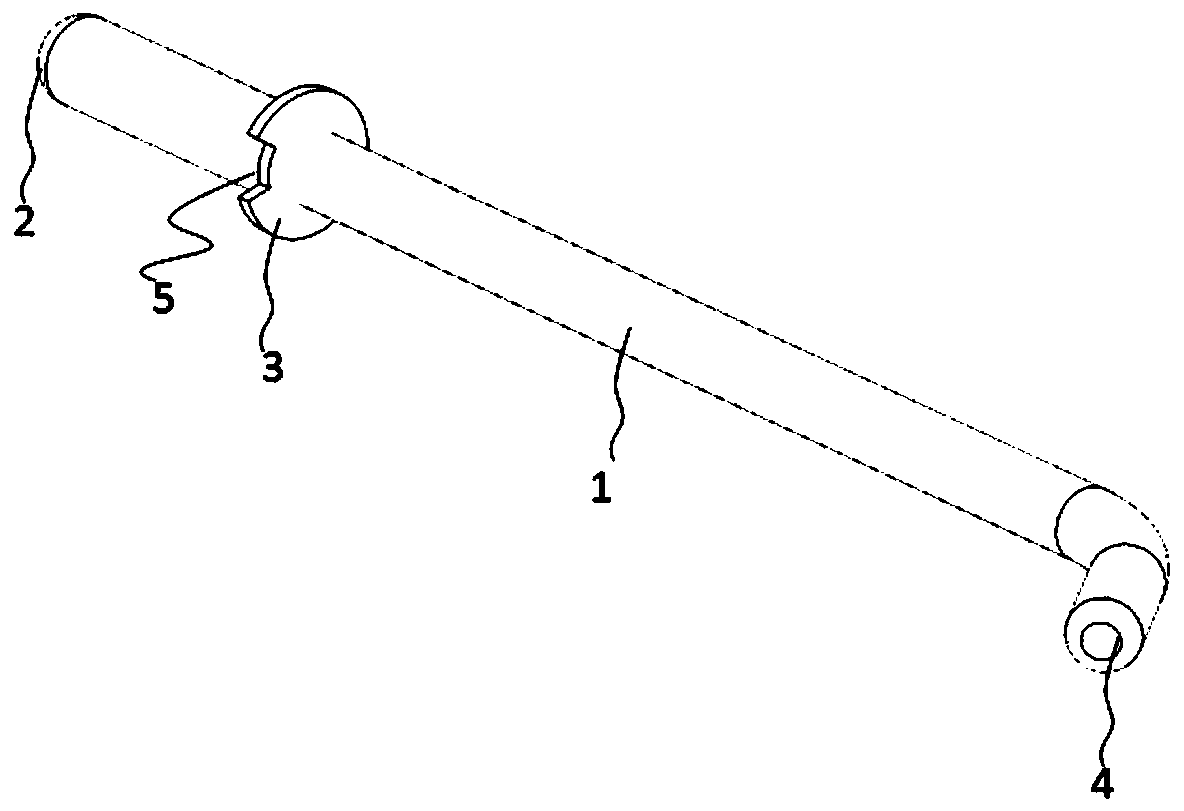

[0023] Such as image 3 As shown: the main body of the movable rod I is a cylindrical long rod 1, the end of the cylindrical long rod 1 is set as a guide round edge 2, the upper end of the cylindrical long rod 1 is provided with a handle 4, and on the cylindrical long rod 1 A circular locking disc 3 is arranged near the end, and the locking disc 3 is provided with an opening 5;

[0024] Such as Figure 4 As shown: the mounting seat II includes a base plate 6, on which a mounting screw hole is provided, on one side of the base plate 6, an upper connecting block 8 and a lower guide connecting block 7 are arranged side by side in parallel, and on the upper connecting bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com