Connecting joint for spray connecting pipe of electric sprayer

An electric sprayer and a technology for connecting joints, which are applied in applications, devices for catching or killing insects, animal husbandry, etc., can solve the problems of human injury, poor connection and sealing, and spilling on the human body, and achieve good sealing effect and fast The effect of installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

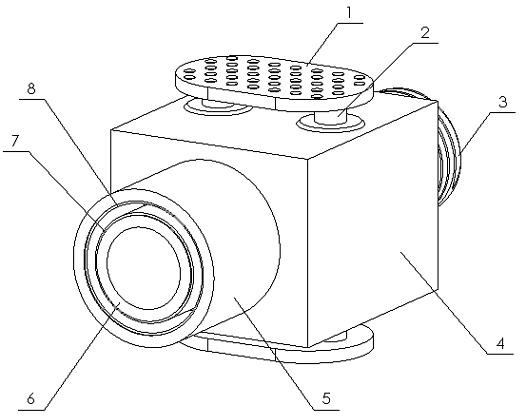

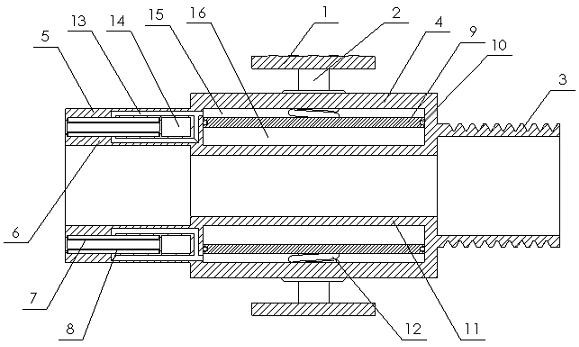

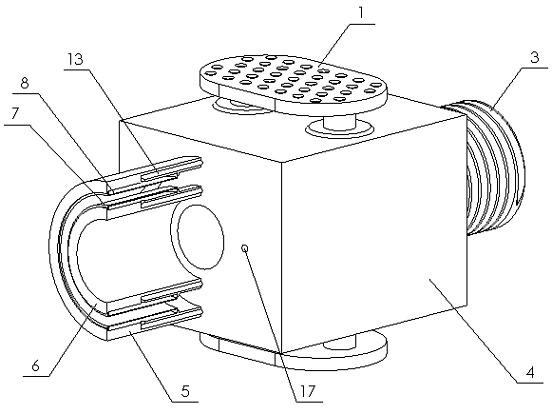

[0016] A connection joint for the spray connection pipe of an electric sprayer of the present invention is realized in the following way: a connection joint for the spray connection pipe of an electric sprayer of the present invention consists of a push button 1, a push rod 2, a connection pipe 3, an outer shell 4, an outer water outlet sleeve 5, an inner Outlet casing 6, inner airbag 7, outer airbag 8, sealing piston 9, sealing ring 10, water pipe 11, spring 12, airbag airway 13, adsorption chamber 14, airbag sealing chamber 15, adsorption sealing chamber 16, adsorption hole 17 Composed of a sealing sleeve 20, the housing 4 is a rectangular shell structure, two pairs of push rods 2 are respectively placed on the upper and lower opposite surfaces of the housing 4, one end of the push rod 2 is placed outside the housing 4, and the push rods 2 are placed outside the housing 4. The other end of the rod 2 passes through the casing 4 and is placed in the casing 4. The connection bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com