Locking mechanism of rotating part, and steel rail grinding device comprising locking mechanism

A technology of rotating parts and locking, which is used in tracks, track laying, track maintenance, etc., can solve the problems of increasing the complexity of the overall mechanism, limited mechanism space, locking failure, etc., and achieves safe, effective and normal operation and small motion friction coefficient. , The effect of not easy to slip off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

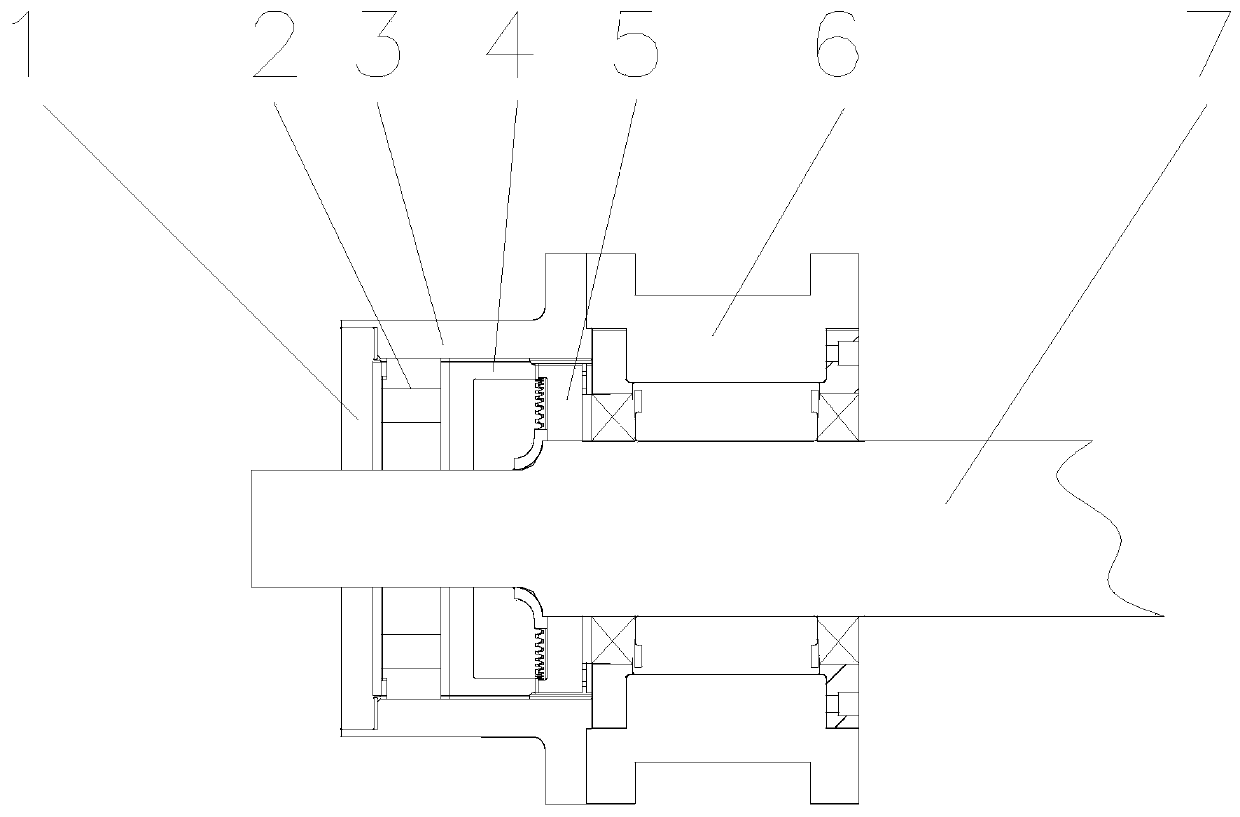

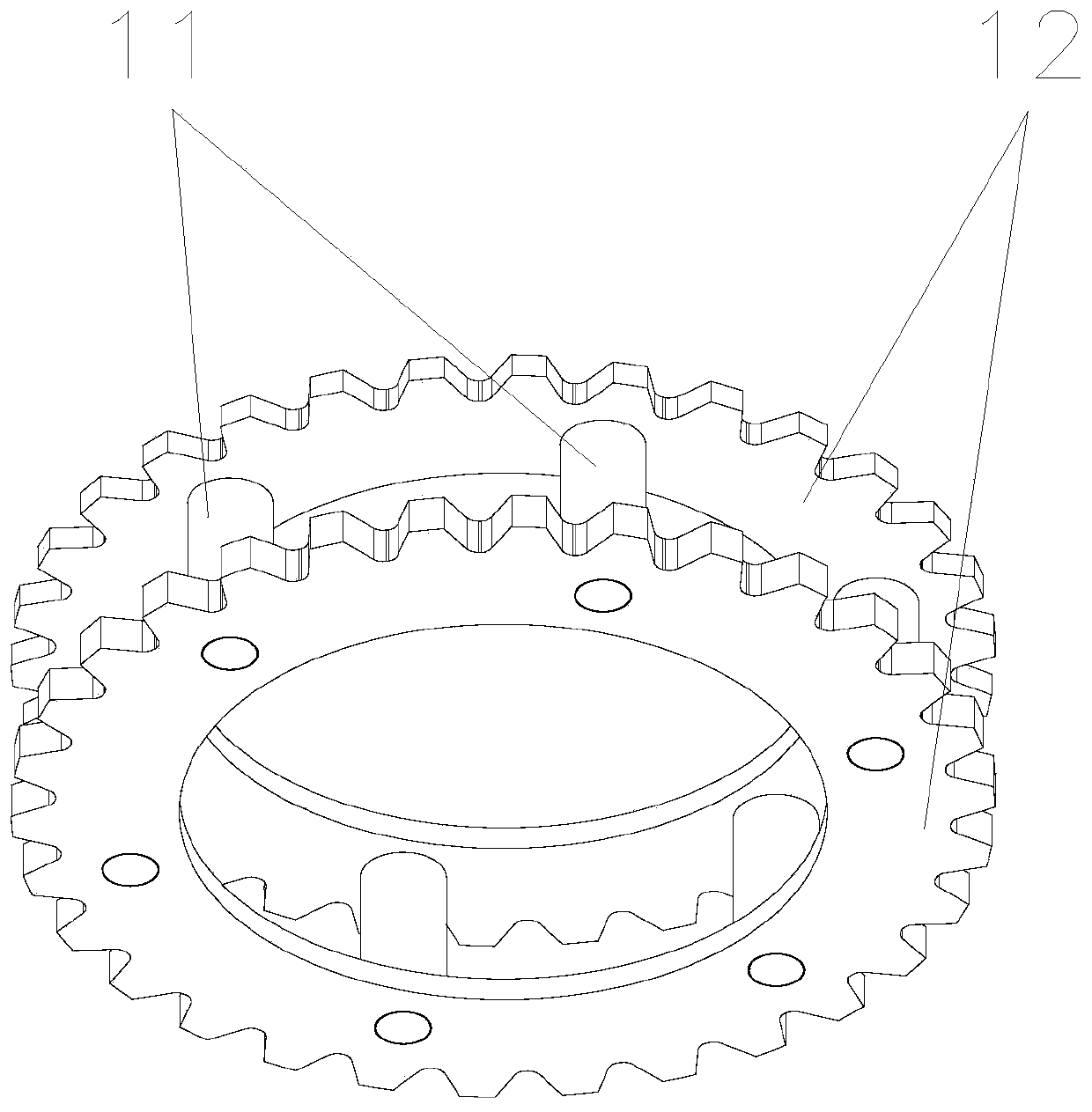

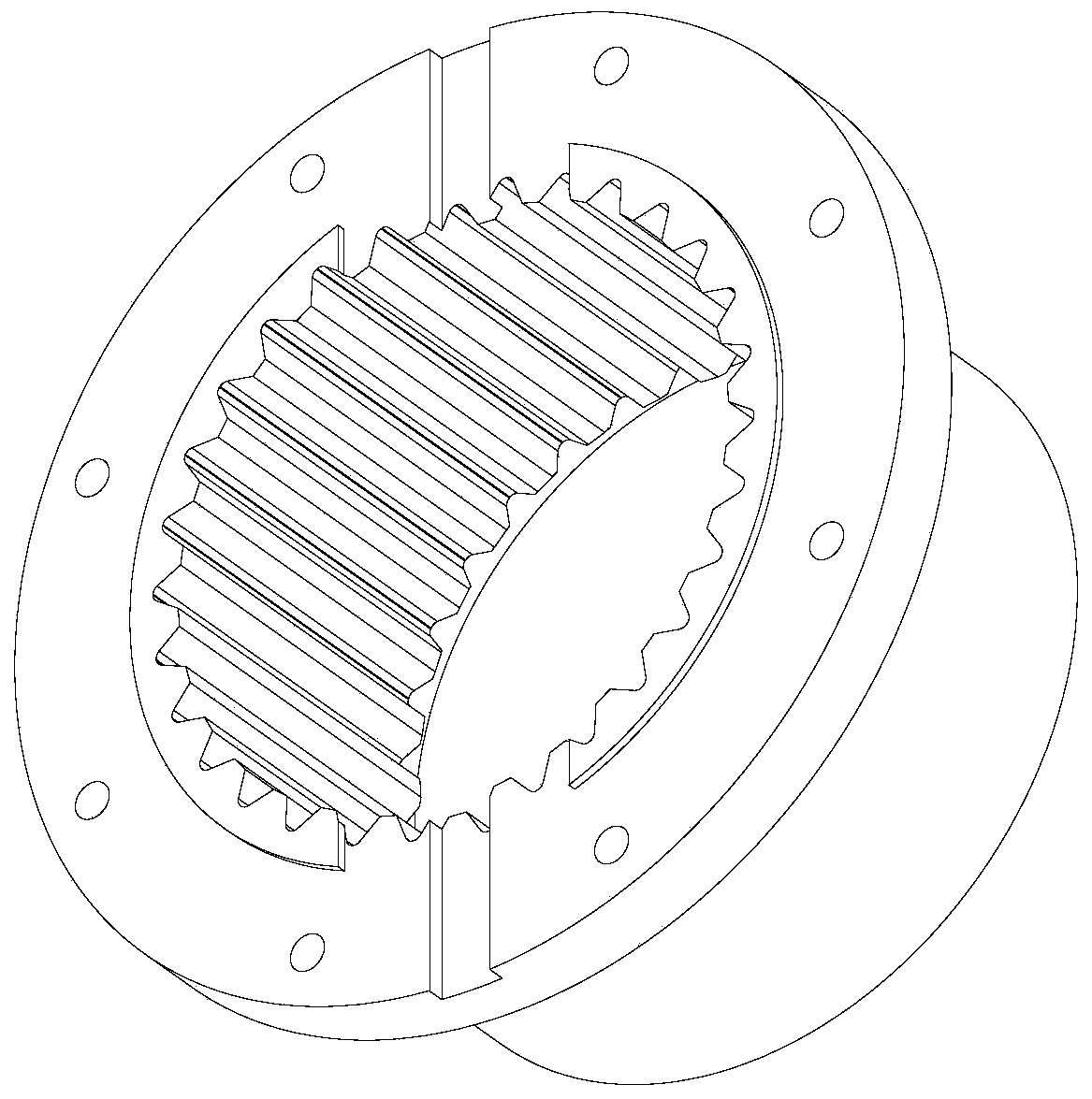

[0040] The present invention provides a locking mechanism for the rotating part 7, the rotating part 7 is coaxially pierced with a fixed locking cylinder 3, and there is formed between the inner wall of the locking cylinder 3 and the outer surface of the rotating part 7 An annular gap; the annular gap is provided with a chainring set that is meshed and connected under the action of a pre-tightening force; the toothed set includes a movable toothed plate 4 that can move in the annular gap, and the middle part of the movable toothed plate 4 is open. There is an avoidance hole and slides through the rotating part 7, and the fixed toothed plate 5 is fixedly sleeved on the rotating part 7. The movable toothed plate 4 and the fixed toothed plate 5 are connected by end teeth; the outer toothed plate 4 The round surface and the inner wall of the locking cylinder 3 are connected by a key that limits the rotation of the movable toothed disc 4 .

[0041] As for the face teeth, many small...

Embodiment 2

[0057] A rail grinding device, including the locking mechanism of the rotating part 7 described in any one of the above technical solutions; the other end of the rotating part 7 is fixedly connected to the rotating part support seat 6, and the rotating part 7 is fixedly connected with Grinding the fixing frame 8, the grinding unit 9 arranged in multiple rows is fixed on the outer periphery of the grinding fixing frame 8.

[0058] There are two groups of rail grinding devices corresponding to the width of the rail on the rail, and a frame body 10 is fixedly connected between the two groups of rail grinding devices.

[0059] When this rail grinding device works, it advances along the length direction of the rail, and there are defects such as cracks or other pits on the top surface of the rail (the surface where the rail is combined with the train roller), which needs to be polished and maintained. During the advance of the rail grinding device, one row of grinding units 9 is ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com