An assembled steel structure building composite sandwich wall panel and its installation method

A steel structure and sandwich wall technology, applied in the direction of protective buildings/shelters, buildings, building types, etc., can solve the problem of poor sound insulation, flame retardancy and earthquake resistance, cannot meet the needs of building construction, and reduce building construction Speed and other issues, to achieve the effect of excellent seismic performance, increased mechanical strength, and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

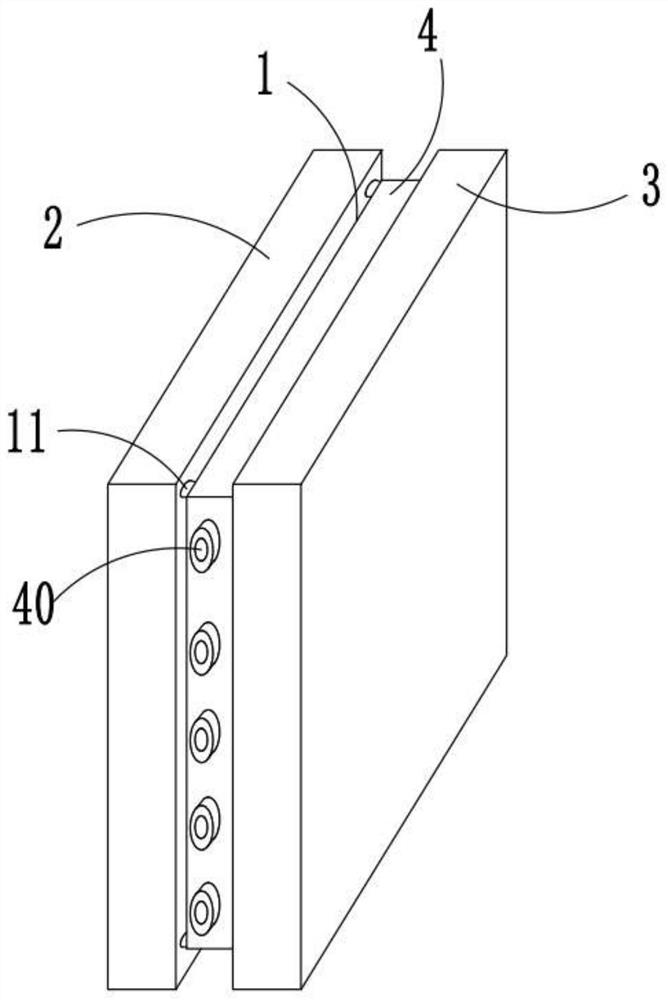

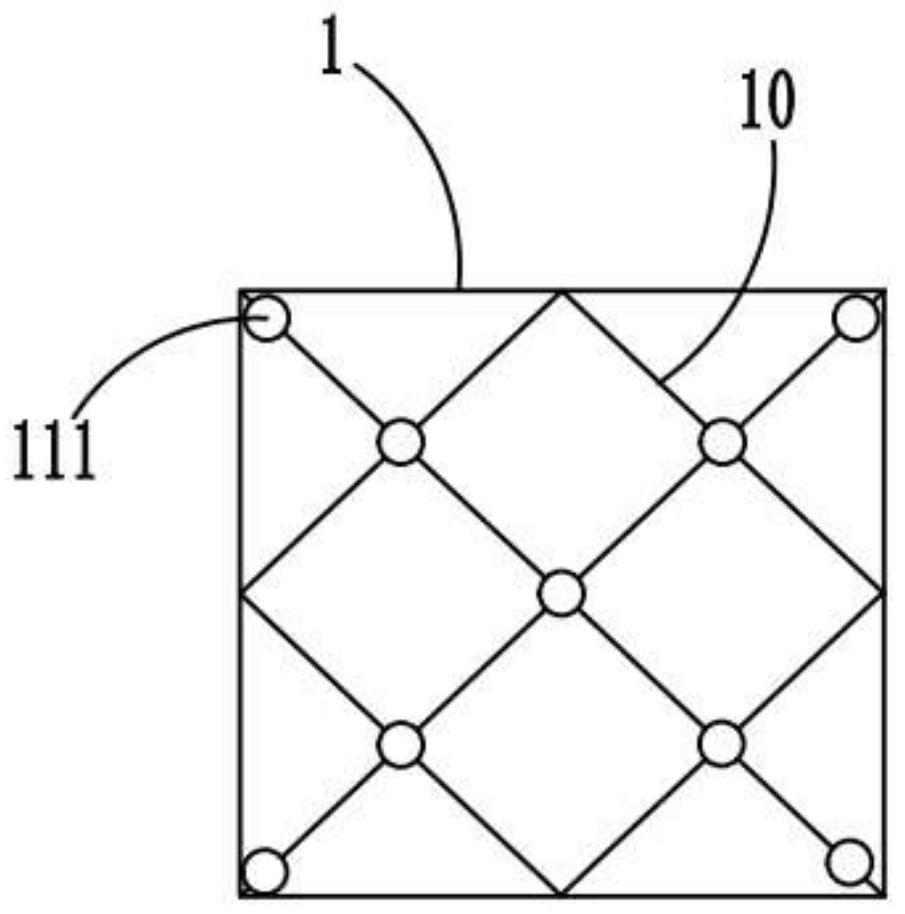

[0041] Example: such as figure 1 , 2The composite sandwich wall panel of a prefabricated steel structure building shown mainly includes a steel frame body 1 with six reinforcing ribs 10 on the side wall, an inner splint 2 fixed on the side wall of the steel frame body 1, and a steel frame body fixed on the side wall. The outer splint 3 on the side away from the inner splint 2 of the body 1, and the thermal insulation sandwich layer 4 arranged inside the steel frame body 1 and bonded to the inner wall of the steel frame body 1;

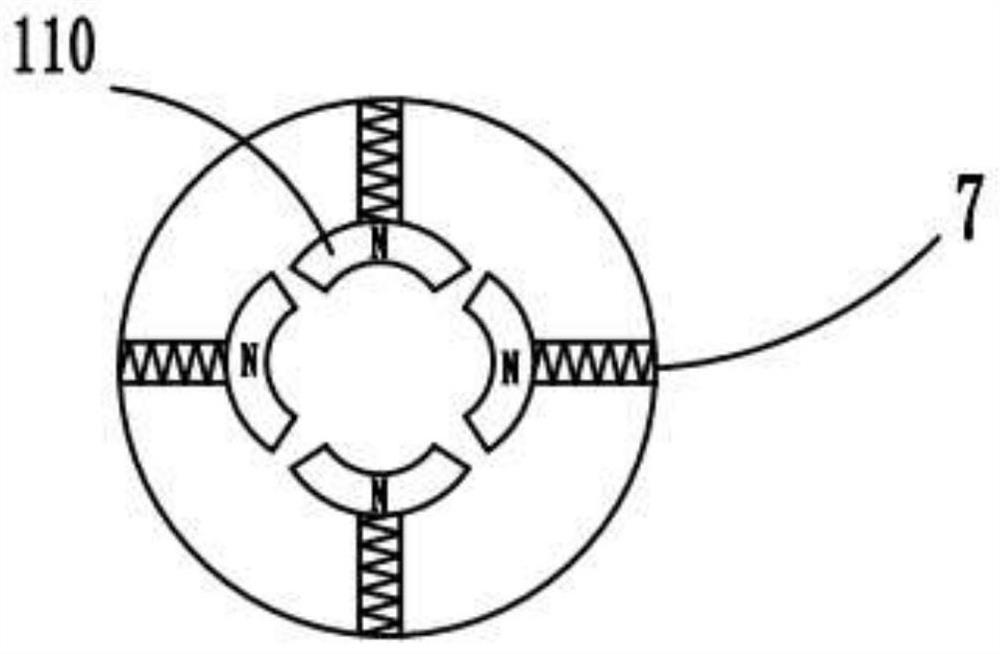

[0042] like Figure 12 , 13 As shown, the inner splint 2 and the outer splint 3 both include a sound-insulating gusset 5 and a flame-retardant gusset 6 that are interlocked with each other, and the side wall of the sound-insulating gusset 5 is provided with three sound-absorbing material frames 50 whose side lengths increase sequentially from the inside to the outside. The side wall of the flame-retardant gusset 6 opposite to the sound-absorbing gus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com