Fuel delivery device for cryogenic fuels, method for operating a fuel delivery device for cryogenic fuels

A low-temperature fuel and fuel delivery technology, which is applied to pump devices, oil supply devices, charging systems, etc., can solve the problems of the efficiency of the fuel delivery device and the large size of the pre-delivery pump, so as to reduce the installation space requirement and reduce the Effect of Pipeline Diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

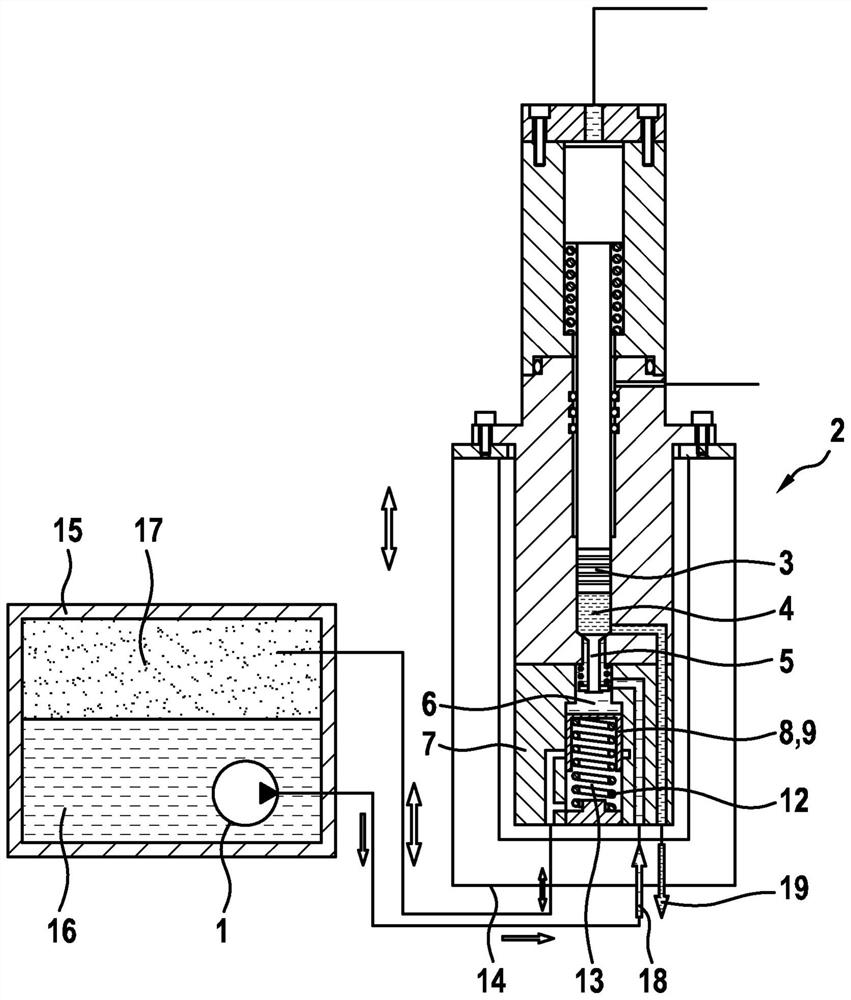

[0024] exist figure 1 The fuel delivery device according to the invention shown in comprises a pre-feed pump 1 and a high-pressure pump 2 , wherein the pre-feed pump 1 is currently arranged in the bottom region of a tank 15 for storing low-temperature fuel. There is a liquid phase 16 of the fuel, which is covered by a gas phase 17 of the fuel. The arrangement of the pre-feed pump 1 in the tank 15 has the advantage that the structural outlay for connecting the pre-feed pump 1 to the high-pressure pump 2 is reduced, since only the low-pressure line 18 needs to be led out of the tank 15 . The pre-feed pump 1 can in particular be embodied as a side channel pump or a centrifugal pump.

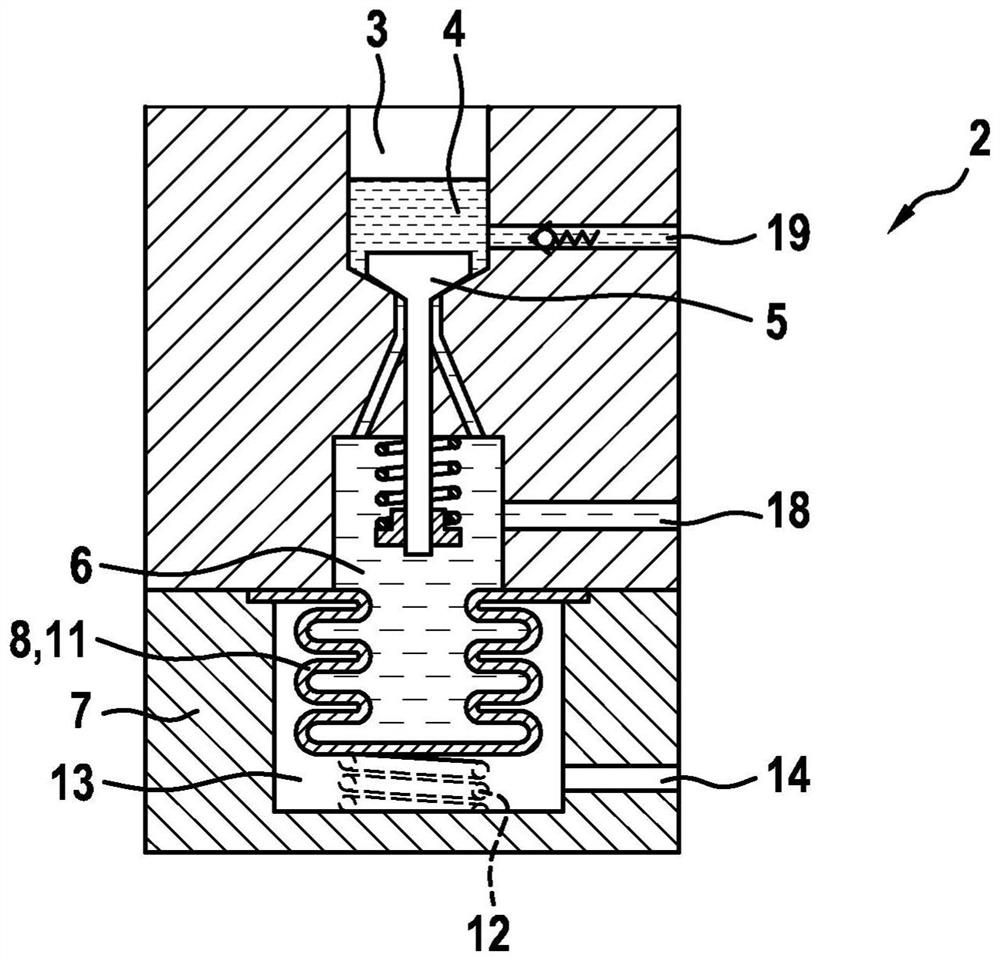

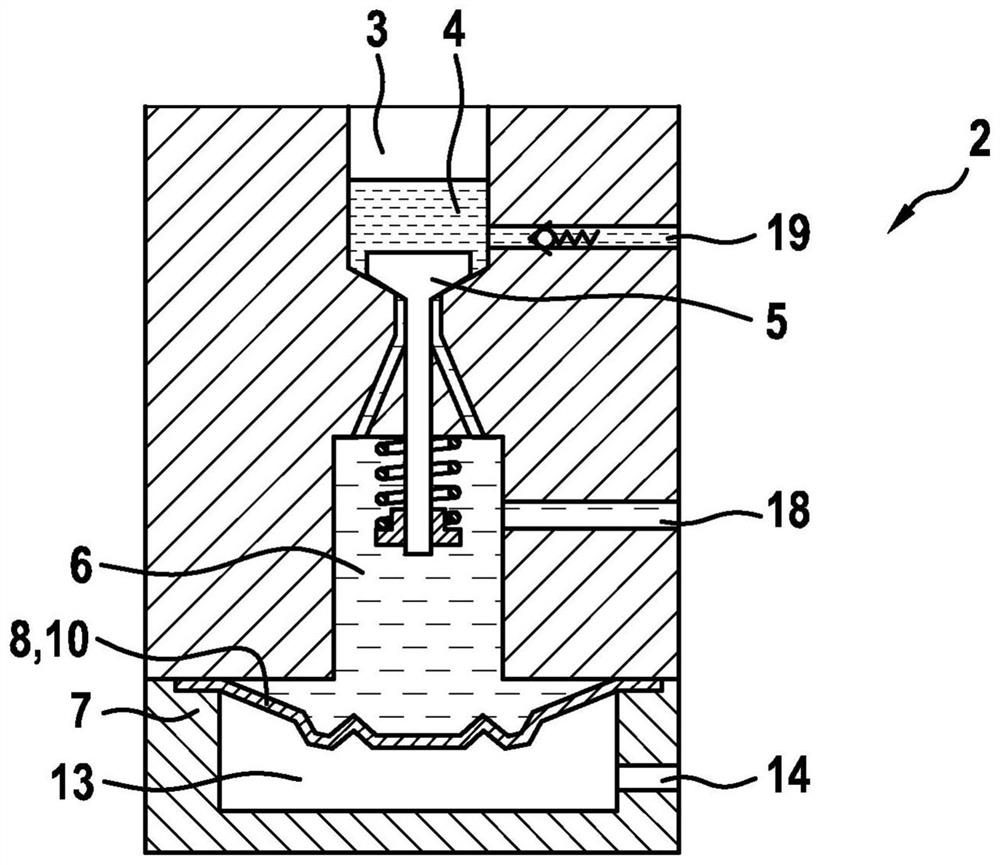

[0025] The additionally provided high-pressure pump 2 is embodied as a single-piston pump. The single-piston pump has a compression chamber 4 which is bounded by a reciprocating piston 3 and which can be filled with cryogenic fuel via a suction valve 5 . Here, the fuel is drawn from a low-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com