Screening assembly and mobile material processing machine

A component and screening technology, applied in grain processing, grading, sieving, etc., can solve problems such as flexibility, cost saving or energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

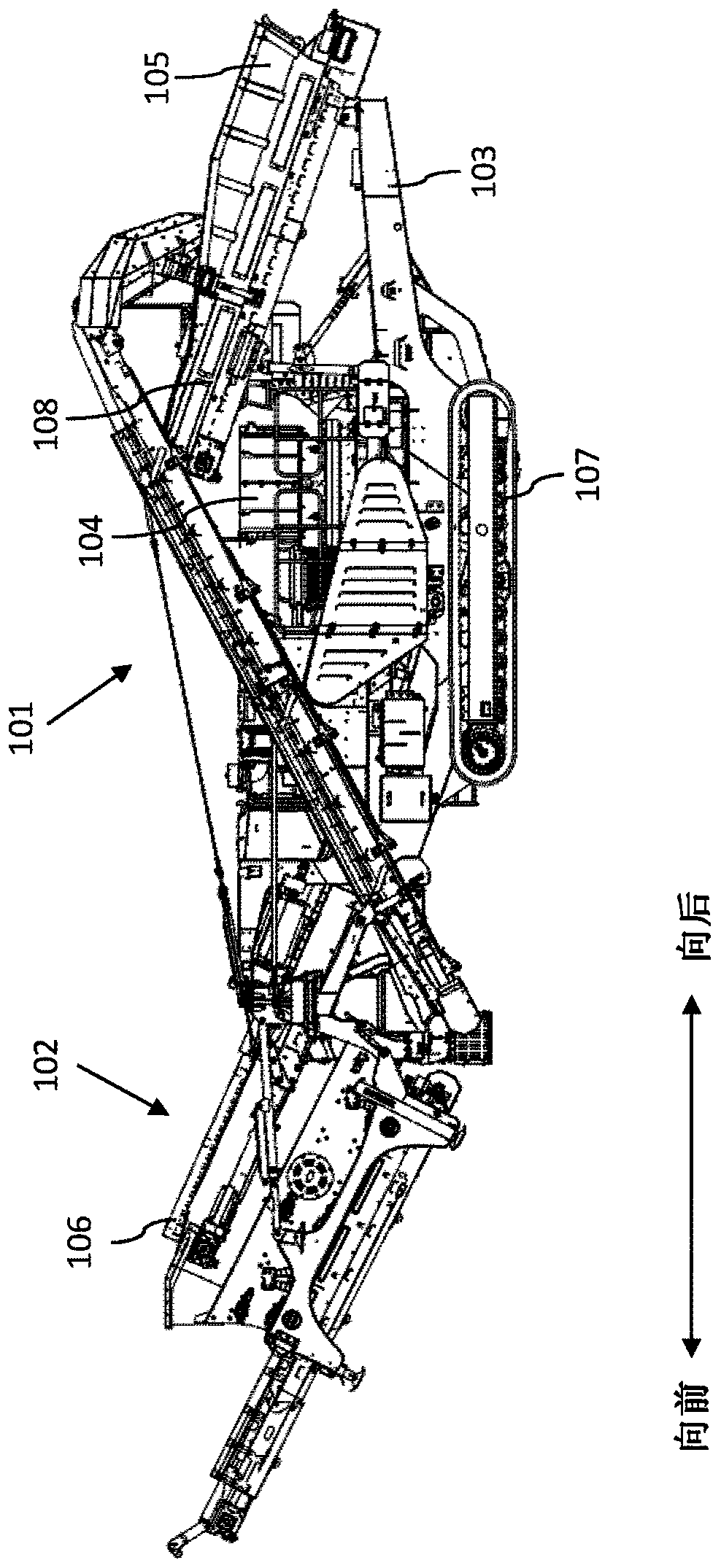

[0046] refer to figure 2 , the mobile material processing equipment includes a mobile crusher 101 and a screening assembly 102, and the screening assembly 102 can be rigidly or detachably installed on the mobile crusher. The plant comprises a machine main frame 103 carrying a crushing unit 104 at the rearward end, such as a cone crusher or jaw crusher or impact crusher etc., which also supports a belt conveyor 108 to Supply material to the crushing unit. A chute or hopper 105 is arranged above the conveyor to hold material. Alternatively, a vibrating feeder can be used to move material forward to the jaw / impact crusher. A supply conveyor 106 is arranged on the main frame for transporting the material processed by the crusher to the screening assembly 102 so that the material reaches the forward end of the apparatus. The machine main frame is mounted via the chassis on tracks 107 on both sides to make the material handling equipment mobile.

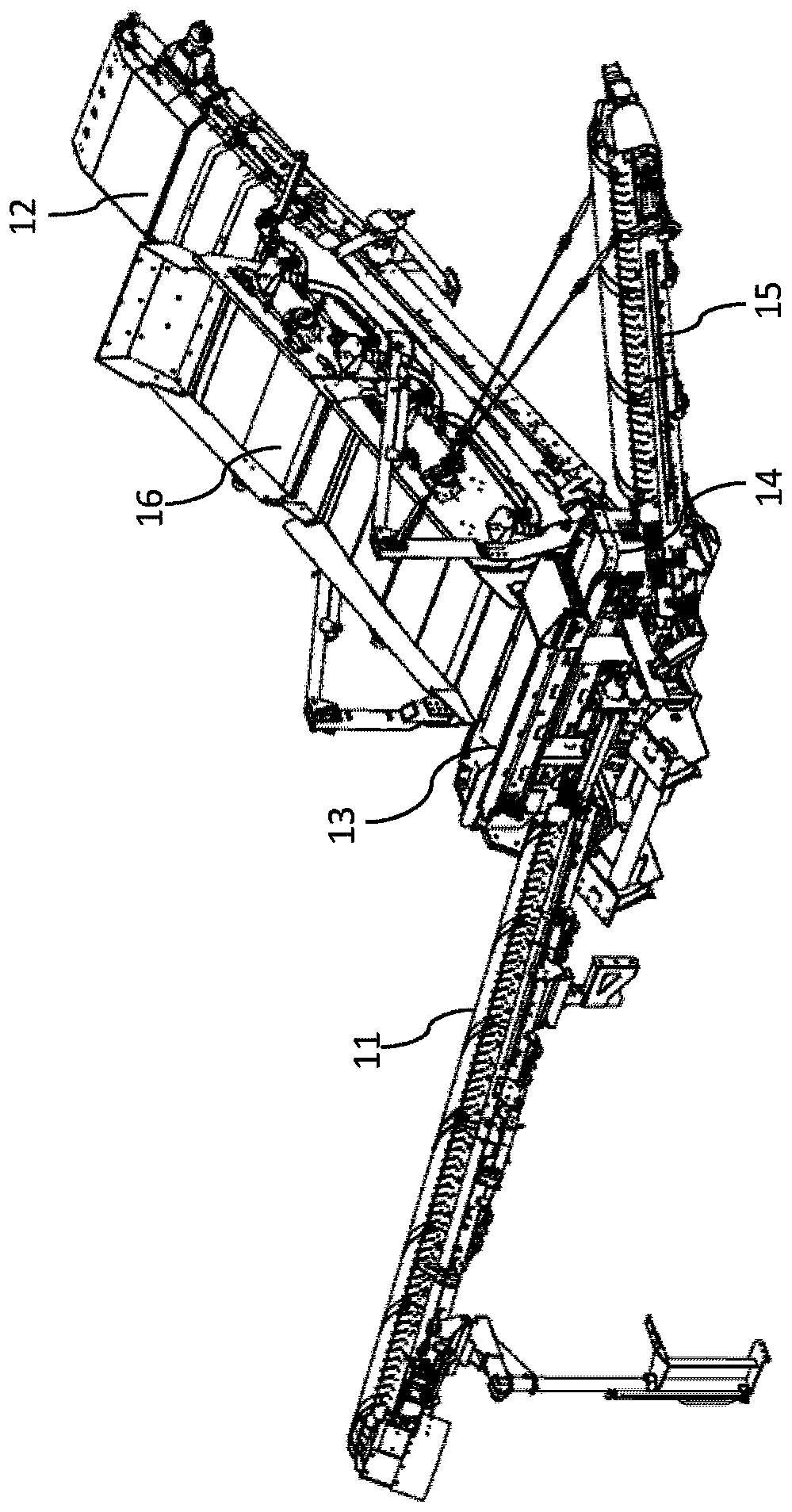

[0047] Figure 3a A perspecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com