High-efficiency glass shell metal texture surface treatment equipment and method

A surface treatment and metal texture technology, applied in the field of high-efficiency glass casing metal texture surface treatment equipment, can solve the problems of inability to obtain metal texture surface texture effects, limited production efficiency, and failure to achieve precise temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

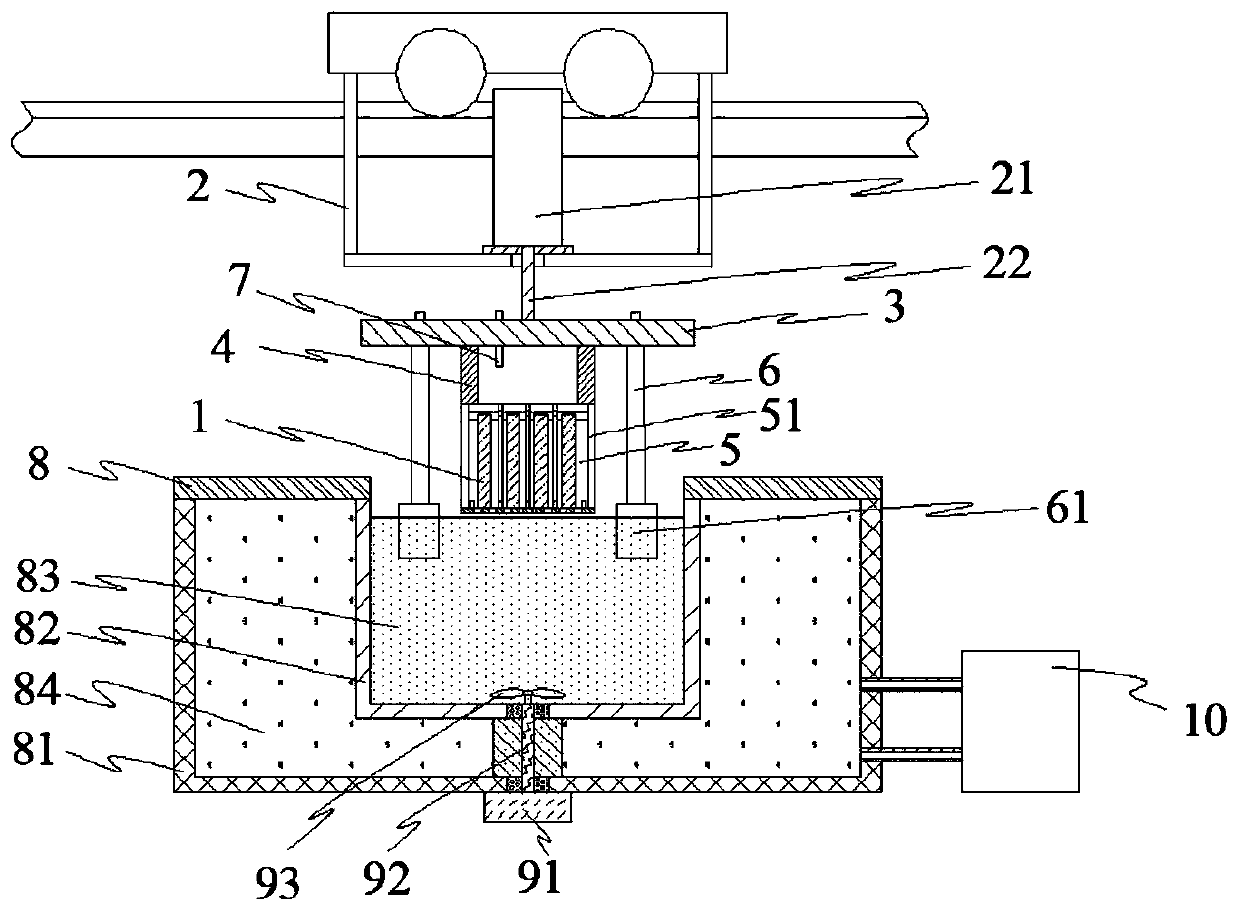

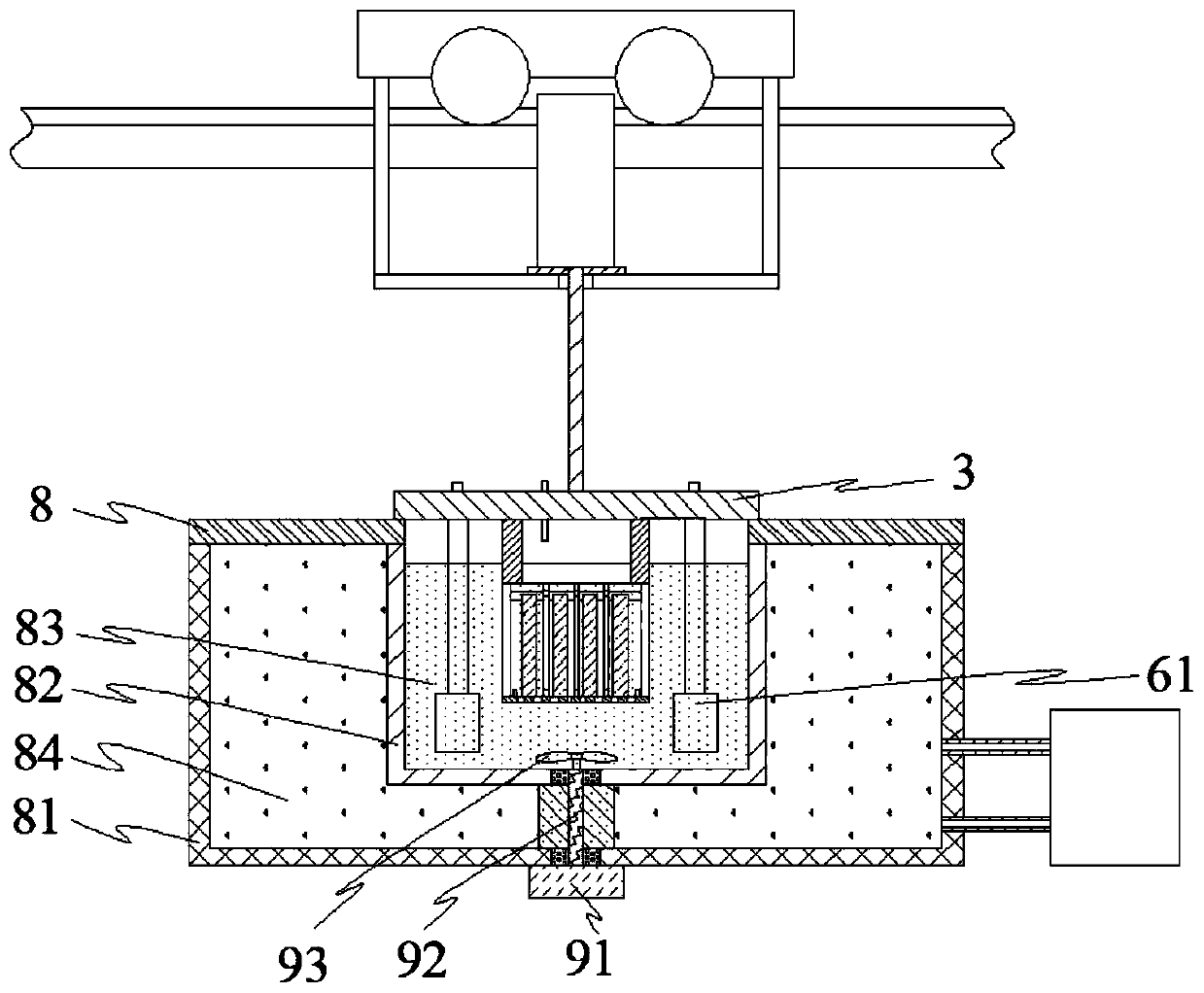

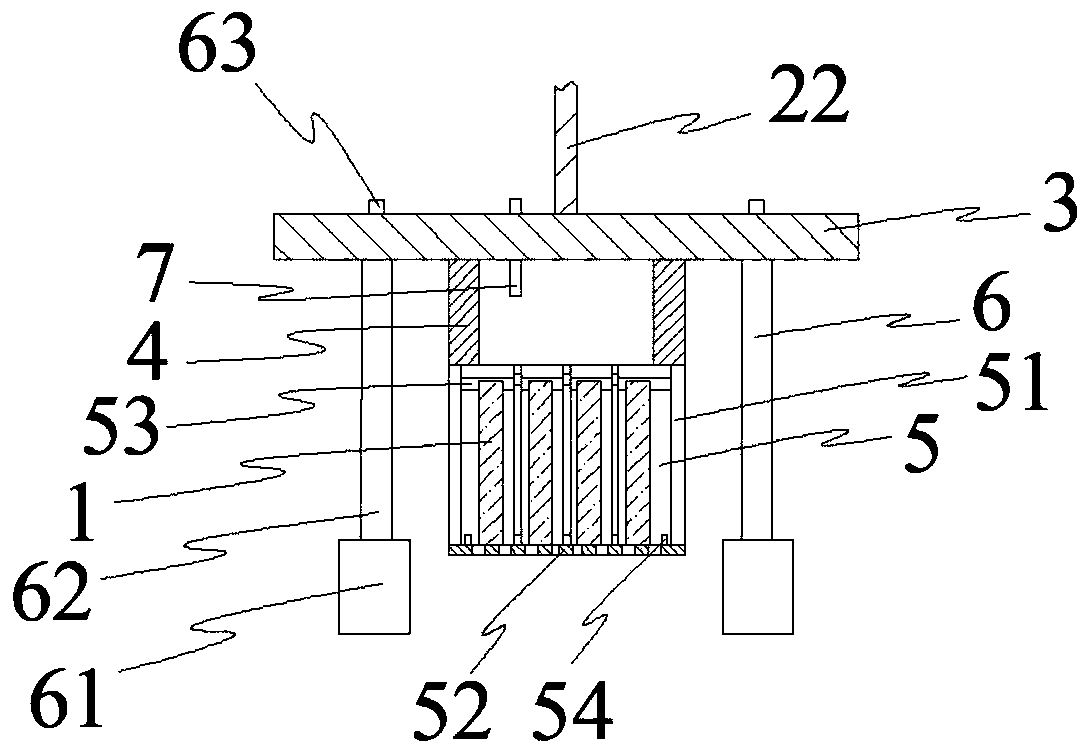

[0038] Please refer to Figure 1 to Figure 4 , a high-efficiency metal texture surface treatment equipment for glass casings, used for surface treatment of glass casings 1 to achieve metal texture surface effects, is provided with an etching tank 8, a material frame, and a fixing frame 2, and the etching groove 8 is set There is a low-temperature bath 81 and an inner tank 82, the inner tank 82 is provided with an etching liquid 83, the fixed frame 2 is provided with a hydraulic cylinder 21, and the hydraulic cylinder 21 is provided with an ejector rod 22, and the material frame is installed At the lower end of the ejector rod 22, the material frame is provided with a top cover 3, a connecting rod 4, a frame body 5, a cold trap body 6, and an infrared temperature sensor 7, and the top of the top cover 3 is connected with the ejector rod 22 , the connecting rod 4 is installed on the lower surface of the top cover 3, the frame body 5 is arranged on the lower end of the connecting...

Embodiment 2

[0067] A high-efficiency glass casing metal texture surface treatment method, the treatment method also includes between S104 and S105:

[0068] S107: After the timing starts, the ejector rod 22 drives the material frame to shake vertically up and down in a small range, and the frame body 5 is always immersed in the liquid surface of the etching liquid 83 during the shaking process.

[0069] All the other are the same as the first embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap