Roller column rotary rolling machine

A roll column and rolling mill technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of small unformed area, low spin rolling yield, material plastic accumulation, etc., and reach the forming area. Small, good molding quality and yield, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

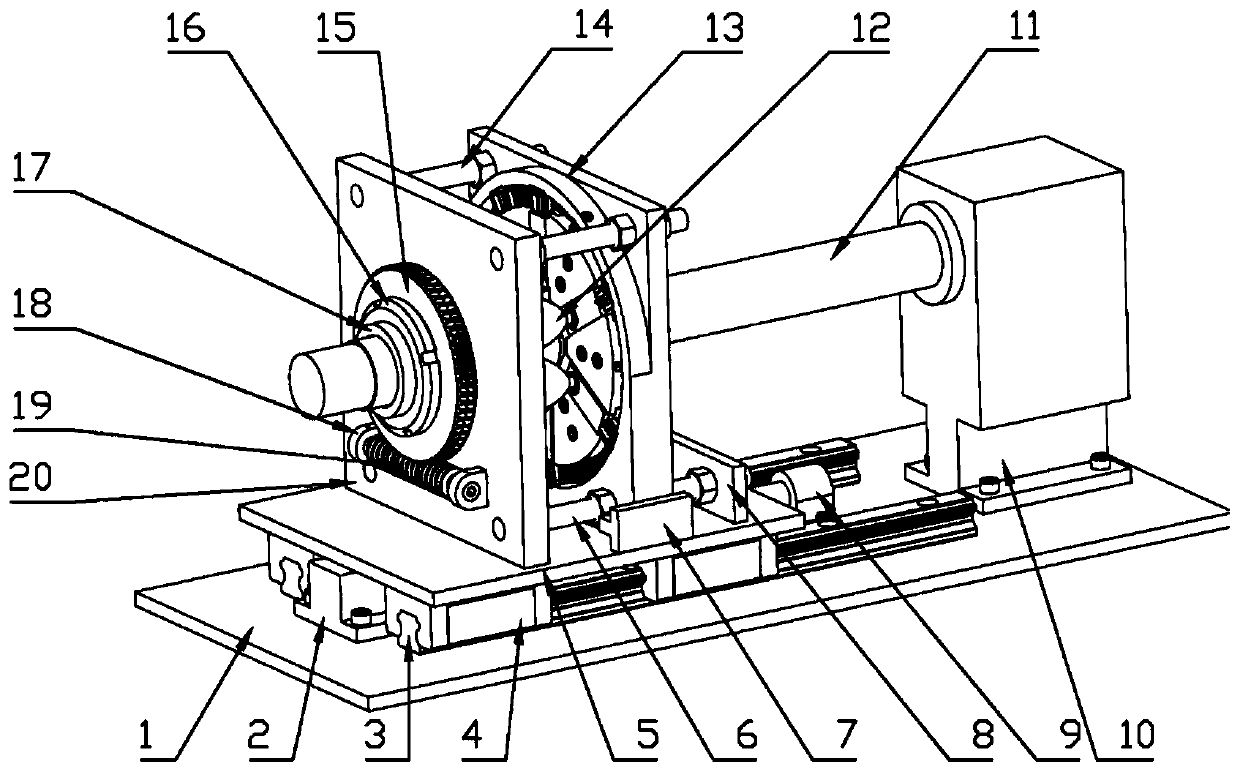

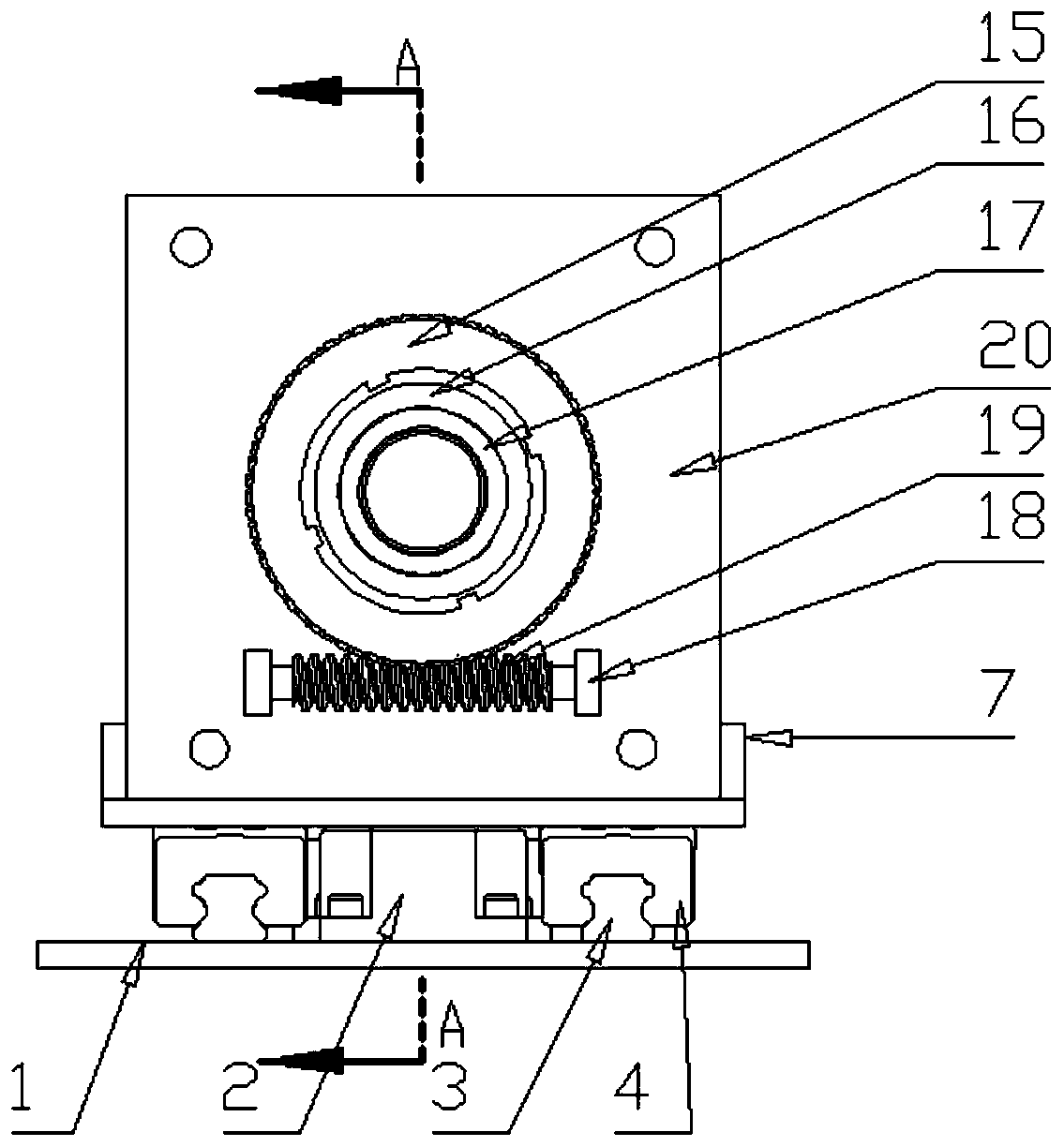

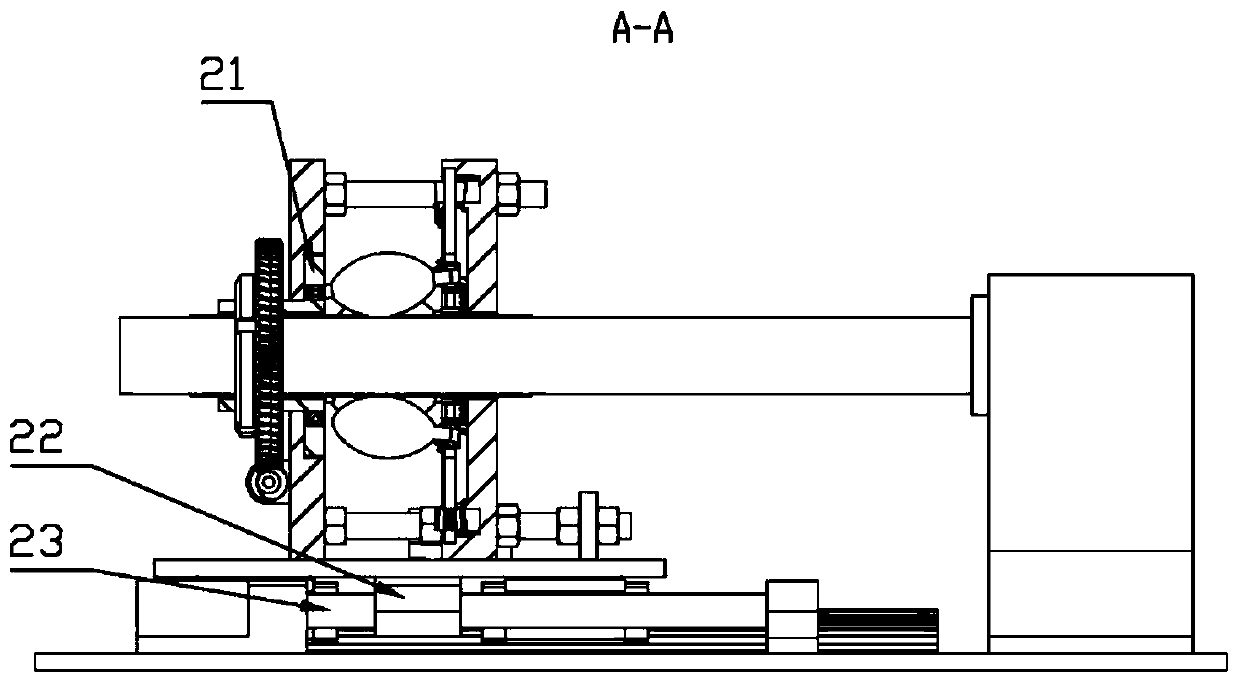

[0026] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0027] like Figure 1-7 As shown, a roll rolling mill in this embodiment includes a base plate 1 and a mandrel driving mechanism, and further includes a feed mechanism, an angle adjustment mechanism and a depression adjustment mechanism 13, and the feed mechanism is arranged on the base plate. On the upper plane of 1, the angle adjustment mechanism and the pressing adjustment mechanism 13 are arranged on the upper plane of the feeding platform 5 in the feeding mechanism, and the core mold driving mechanism is arranged at one end of the upper plane of the base plate 1;

[0028] The core mold driving mechanism includes a core mold 11 and a core mold driving motor 10. The core mold driving motor 10 is arranged at one end of the upper plane of the base plate 1, and one end of the core mold 11 is connected to the output shaft of the core mold driving motor 10....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap