Test device for rapidly evaluating atmospheric wind stress corrosion and test method thereof

A stress corrosion and test device technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of low evaluation efficiency, complex structure, monitoring and evaluation, etc., to achieve a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

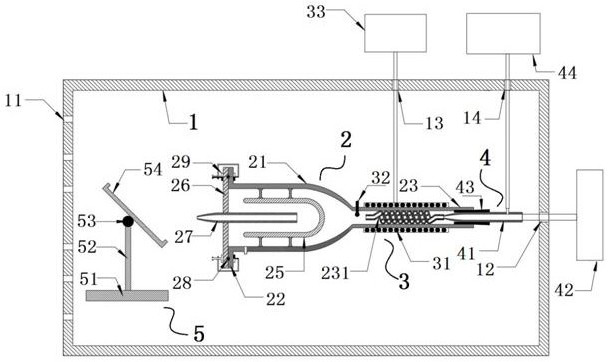

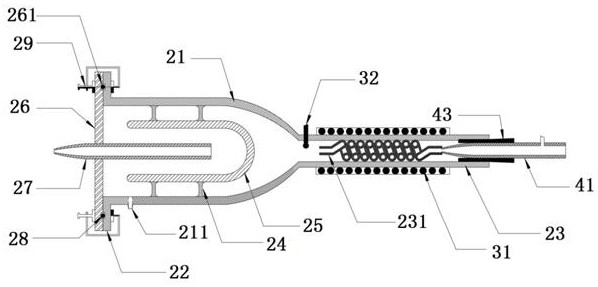

[0058] A test device for quickly evaluating atmospheric wind stress corrosion, comprising a test box 1, characterized in that the test box is provided with an atmosphere chamber assembly 2, and the atmosphere chamber assembly is respectively connected with a temperature and humidity control module 3, a wind A flow control module 4, one side of the atmosphere chamber assembly is provided with a sample holder 5;

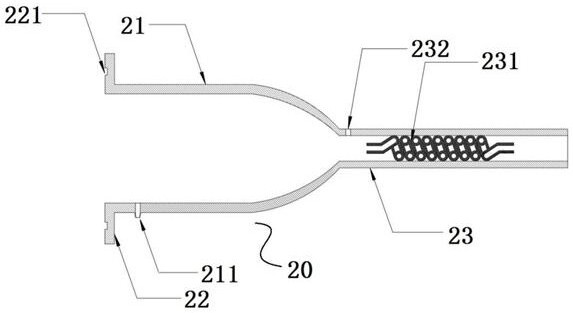

[0059] The atmosphere chamber assembly includes a cavity body 21, openings are respectively provided on both sides of the cavity body, a connecting portion 22 is provided on the outer edge of one opening of the cavity body, and a connecting portion 22 is provided at the opening of the other side of the cavity body. There is a straight pipe portion 23;

[0060] The cavity is provided with a fixed ear 24 and a return cover 25, the return cover is arranged in the central area of the cavity, and fixed ears are arranged symmetrically on the outside of the return cover, an...

Embodiment 2

[0080] A test device for quickly evaluating atmospheric wind stress corrosion, comprising a test box 1, characterized in that the test box is provided with an atmosphere chamber assembly 2, and the atmosphere chamber assembly is respectively connected with a temperature and humidity control module 3, a wind A flow control module 4, one side of the atmosphere chamber assembly is provided with a sample holder 5;

[0081] The atmosphere chamber assembly includes a cavity body 21, openings are respectively provided on both sides of the cavity body, a connecting portion 22 is provided on the outer edge of one opening of the cavity body, and a connecting portion 22 is provided at the opening of the other side of the cavity body. There is a straight pipe portion 23;

[0082] The cavity is provided with a fixed ear 24 and a return cover 25, the return cover is arranged in the central area of the cavity, and fixed ears are arranged symmetrically on the outside of the return cover, an...

Embodiment 3

[0102] The present embodiment provides a kind of test method of the test device of rapid evaluation atmospheric wind stress corrosion described in embodiment 1 or embodiment 2, specifically comprises the following steps:

[0103] After assembling the components of the test device, open the air intake device and adjust the required wind flow rate; then adjust the heating power of the heating part through the temperature and humidity control system to heat up to the temperature required to maintain the wind flow;

[0104] After the flow rate and temperature of the air flow are stable, fix the sample to be evaluated on the sample holder, and adjust the angle between the sample to be evaluated and the air flow by turning the fixing knob of the sample holder to obtain the impact angle required by the air flow;

[0105] After the impact angle of the air flow and its flow velocity and temperature are stabilized, the evaluation of the erosion degree of the sample material to be tested ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com