A method for detecting allergenic peptides of soybean conglycinin and eliminating allergenicity of soybean conglycinin

A soybean conglycinin and sensitization technology, which is applied in the field of detecting soybean conglycinin sensitizing peptides and eliminating soybean conglycinin sensitization, can solve the problem of restricting the application of soybean protein, reducing soybean protein sensitization, reducing soybean protein sensitization, Peptide sensitization and other issues, to achieve the effect of good processing functional properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

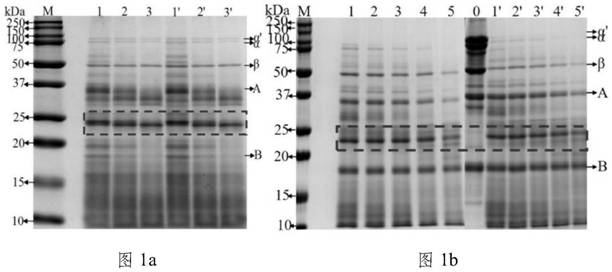

[0075] Heating: Mix soybean conglycinin powder with deionized water to prepare 3% (w / w) soybean conglycinin solution, heat at 70°C for 10min and 20min respectively, place in ice water bath after heating Cool rapidly and store at 4°C.

[0076] Hydrolysis 1: Add pepsin to the heated soybean conglycinin solution, the enzyme amount E / S is 2%, keep the temperature 37°C and pH 1.5 constant during the enzymolysis process, and the enzymolysis time is 30, 60, 120min, Adjust the pH to neutral, and inactivate the enzyme in a boiling water bath for 10 minutes; add trypsin to the heat-treated soybean conglycinin solution, the enzyme amount E / S is 2%, keep the temperature at 37°C and pH 7.0 constant during the enzymolysis process, and the enzyme After the solution time is 10, 20, 30, 60, and 120 minutes, adjust the pH to neutral, and inactivate the enzyme in a boiling water bath for 10 minutes;

[0077] Allergenicity detection: The allergenicity of each enzymatic hydrolyzate in the hydroly...

Embodiment 2

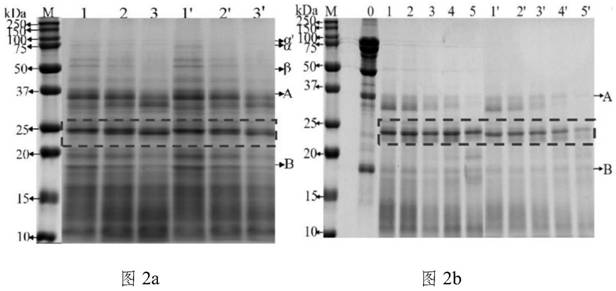

[0087] Heating: Mix soybean conglycinin powder with deionized water to prepare 3% (w / w) soybean conglycinin solution, heat at 80°C respectively for 10min and 20min, place in ice water bath after heating Cool rapidly and store at 4°C.

[0088] Hydrolysis 1: Add pepsin to the heated soybean conglycinin solution, the enzyme amount E / S is 2%, keep the temperature 37°C and pH 1.5 constant during the enzymolysis process, and the enzymolysis time is 30, 60, 120min, Adjust the pH to neutral, and inactivate the enzyme in a boiling water bath for 10 minutes; add trypsin to the heat-treated soybean conglycinin solution, the enzyme amount E / S is 2%, keep the temperature at 37°C and pH 7.0 constant during the enzymolysis process, and the enzyme After the solution time is 10, 20, 30, 60, and 120 minutes, adjust the pH to neutral, and inactivate the enzyme in a boiling water bath for 10 minutes;

[0089] Allergenicity detection: The allergenicity of each enzymatic hydrolyzate in the hydroly...

Embodiment 3

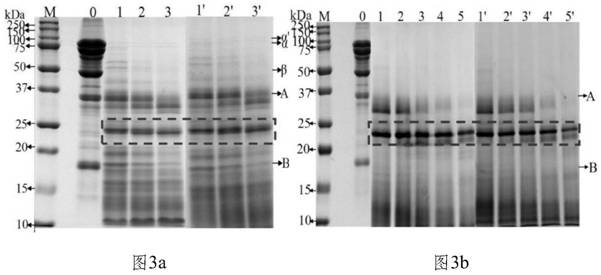

[0099] Heating: Mix soybean conglycinin powder with deionized water to prepare 3% (w / w) soybean conglycinin solution, heat at 90°C for 10min and 20min respectively, place in ice water bath after heating Cool rapidly and store at 4°C.

[0100] Hydrolysis 1: Add pepsin to the heated soybean conglycinin solution, the enzyme amount E / S is 2%, keep the temperature 37°C and pH 1.5 constant during the enzymolysis process, and the enzymolysis time is 30, 60, 120min, Adjust the pH to neutral, and inactivate the enzyme in a boiling water bath for 10 minutes; add trypsin to the heat-treated soybean conglycinin solution, the enzyme amount E / S is 2%, keep the temperature at 37°C and pH 7.0 constant during the enzymolysis process, and the enzyme After the solution time is 10, 20, 30, 60, and 120 minutes, adjust the pH to neutral, and inactivate the enzyme in a boiling water bath for 10 minutes;

[0101] Allergenicity detection: The allergenicity of each enzymatic hydrolyzate in the hydroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com