Patents

Literature

42 results about "Beta-conglycinin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermostable proteases

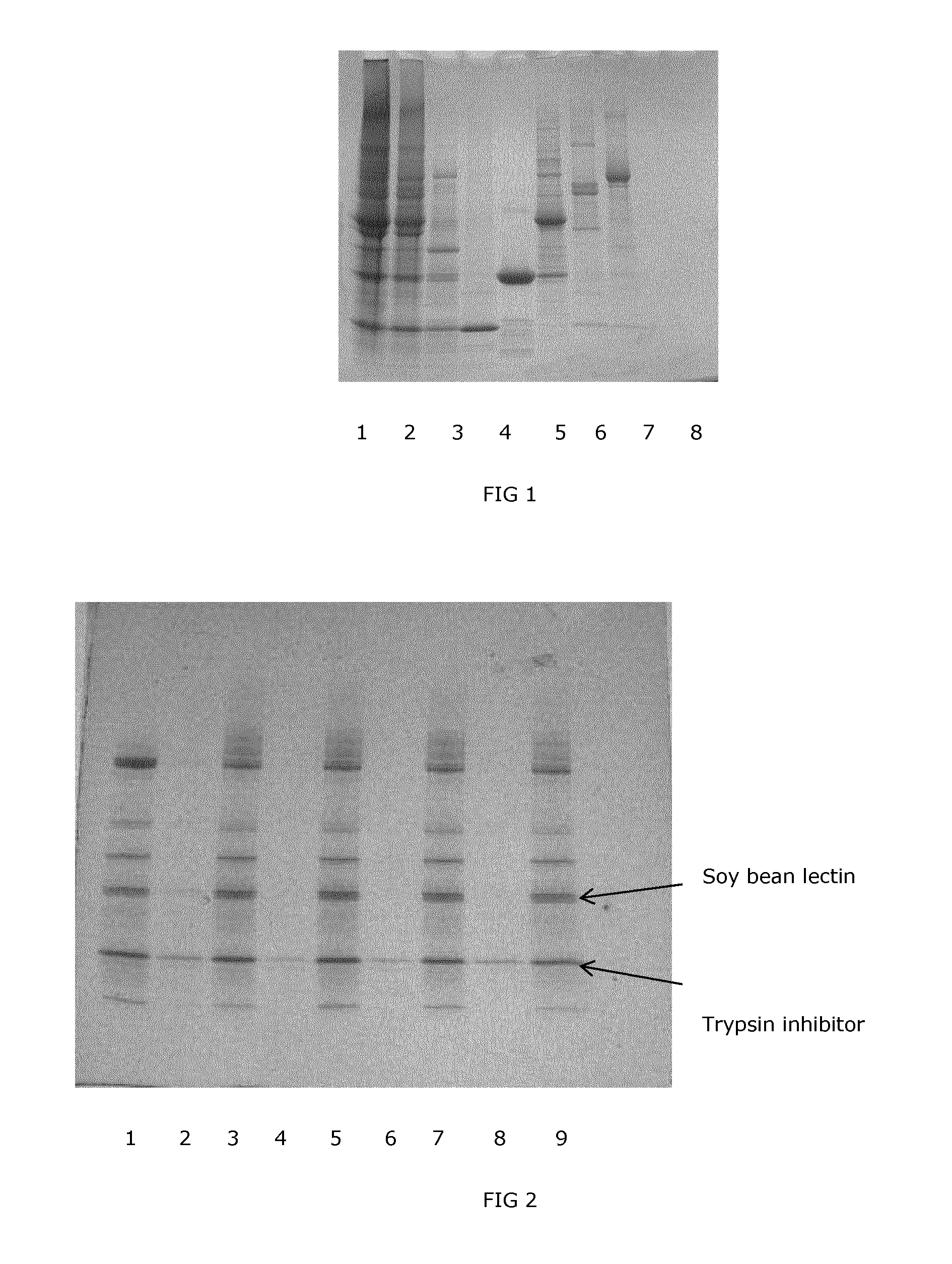

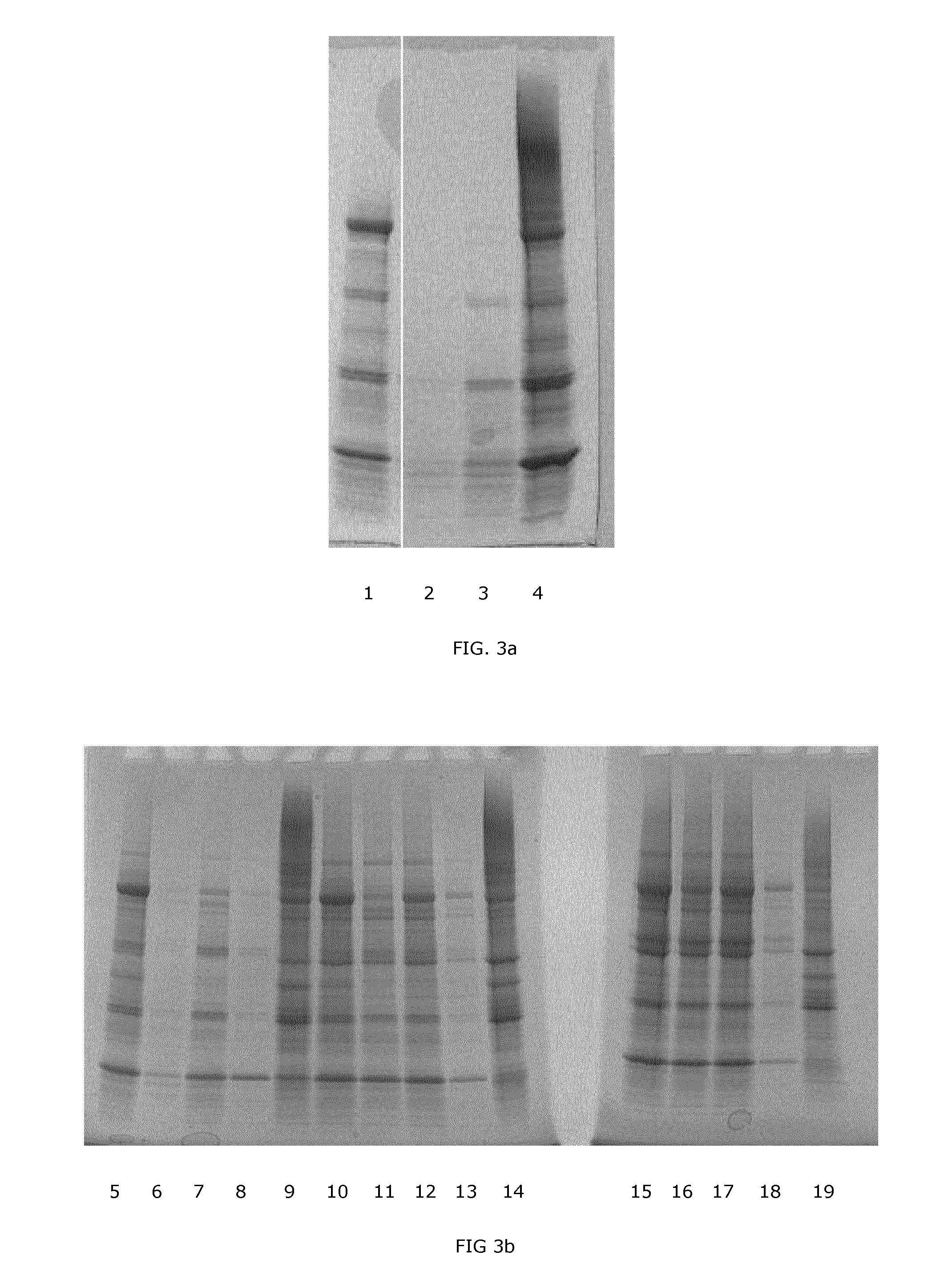

InactiveUS7179630B2High nutritional valueIncrease the degree of hydrolysisFatty acid chemical modificationDough treatmentWild typeTrypsin inhibitor

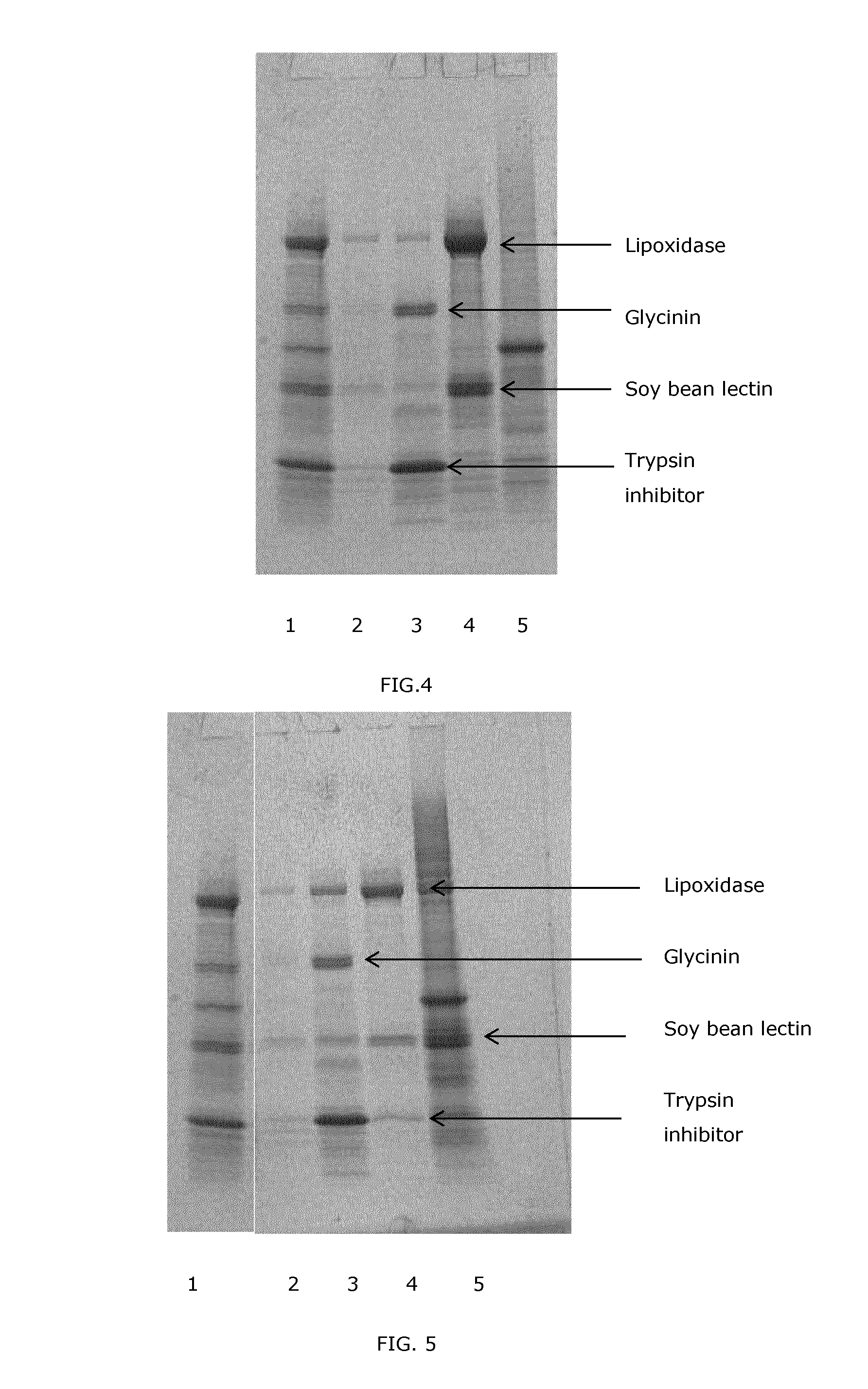

The present invention relates to thermostable proteases having an amino acid sequence which homologous to the amino acid sequence of proteases derived from Nocardiopsis, and the production thereof by wild-type and recombinant host cells including transgenic plants and non-human transgenic animals. The proteases are effective in animal feed, in particular fish feed, and detergents. The proteases are capable of degrading the soybean Bowman-Birk inhibitor, and other antinutritional factors such as soybean agglutinin and the Kunitz trypsin inhibitor, as well as the isolated soy storage proteins glycinin and beta-conglycinin. Characteristic structural features of relevance for the thermostability of these proteases of peptidase family S2A or S1E are disclosed.

Owner:NOVOZYMES AS

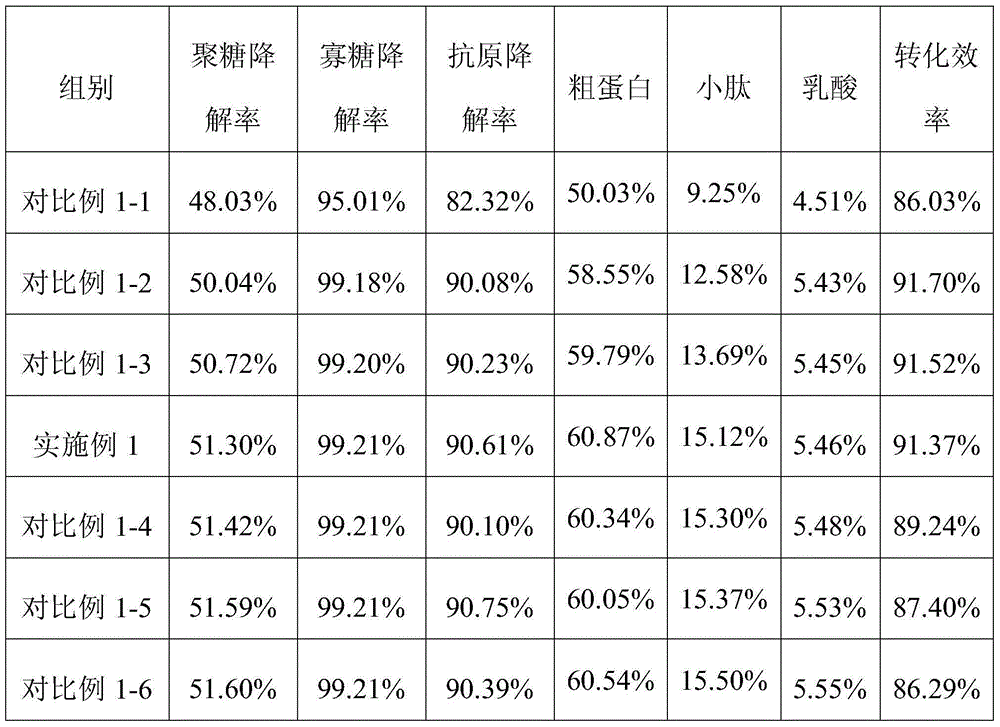

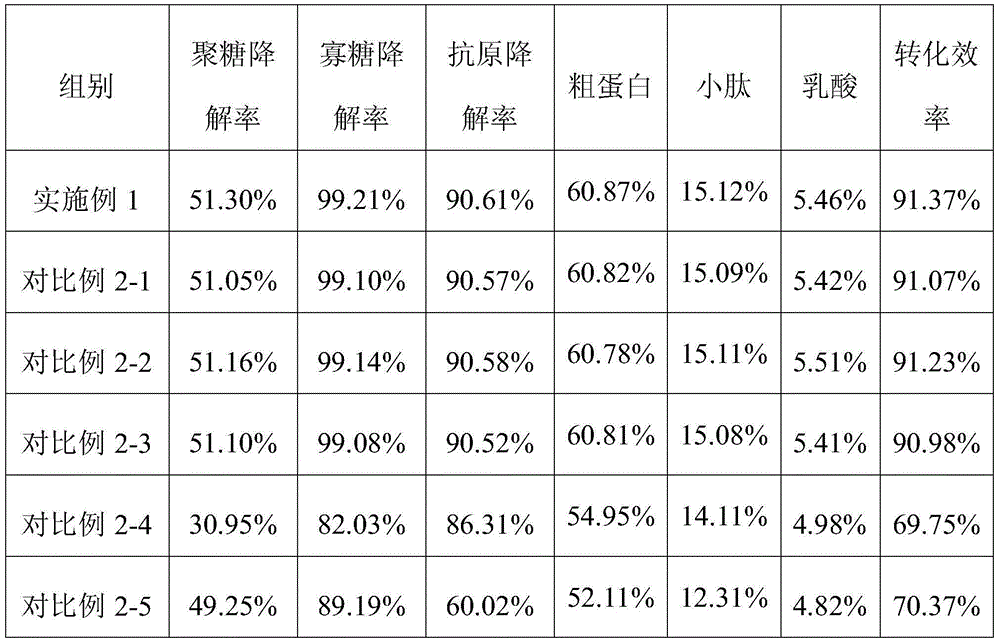

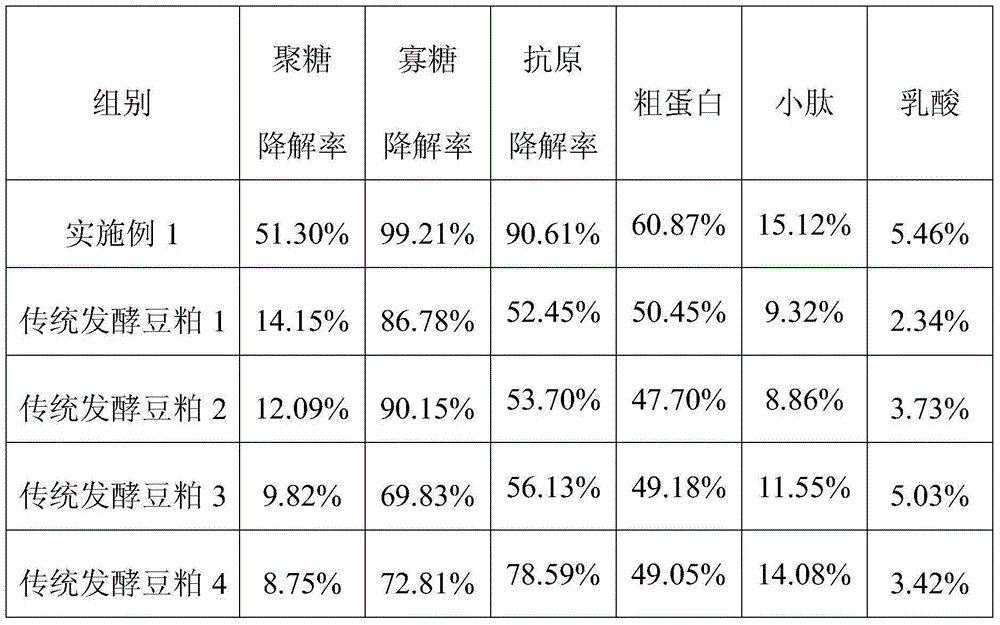

Preparation method of fermented soybean meal for feeding

InactiveCN104824337AImprove digestion utilizationImprove degradation rateAnimal feeding stuffNutritive valuesPhytic acid

The invention discloses a preparation method of fermented soybean meal for feeding. The preparation method includes inoculating mixed bacteria solution into fermented soybean meal substrate and uniformly mixing; fermenting for 72 to 96 hours at 27-37 degrees Centigrade; drying and smashing to obtain fermented soybean meal for feeding. The mixed bacteria solution is composed of aspergillus niger liquid, saccharomycetes liquid, bacillus subtilis liquid and lactic acid bacteria liquid. The weight ratio of the mixed bacteria solution to the fermented soybean meal substrate is 6-18:1000, and the weight ratio of aspergillus niger liquid, saccharomycetes liquid, bacillus subtilis liquid and lactic acid bacteria liquid is 1-4:0.5-2:0.5-2:0.5-2. By the preparation method, polysaccharide in the fermented soybean meal can be effectively degraded, nutrient substance in the soybean meal is released, and crude protein of the fermented soybean meal is concentrated. Meanwhile, antinutritional factors such as glycinin, beta-conglycinin, oligosaccharide and phytic acid are effectively degraded, digestive utilization rate of nutrients is increased, and the key problems that glycan content in the fermented soybean meal is high and crude protein is hard to improve and poor in nutritive value are solved.

Owner:NEW HOPE LIUHE +1

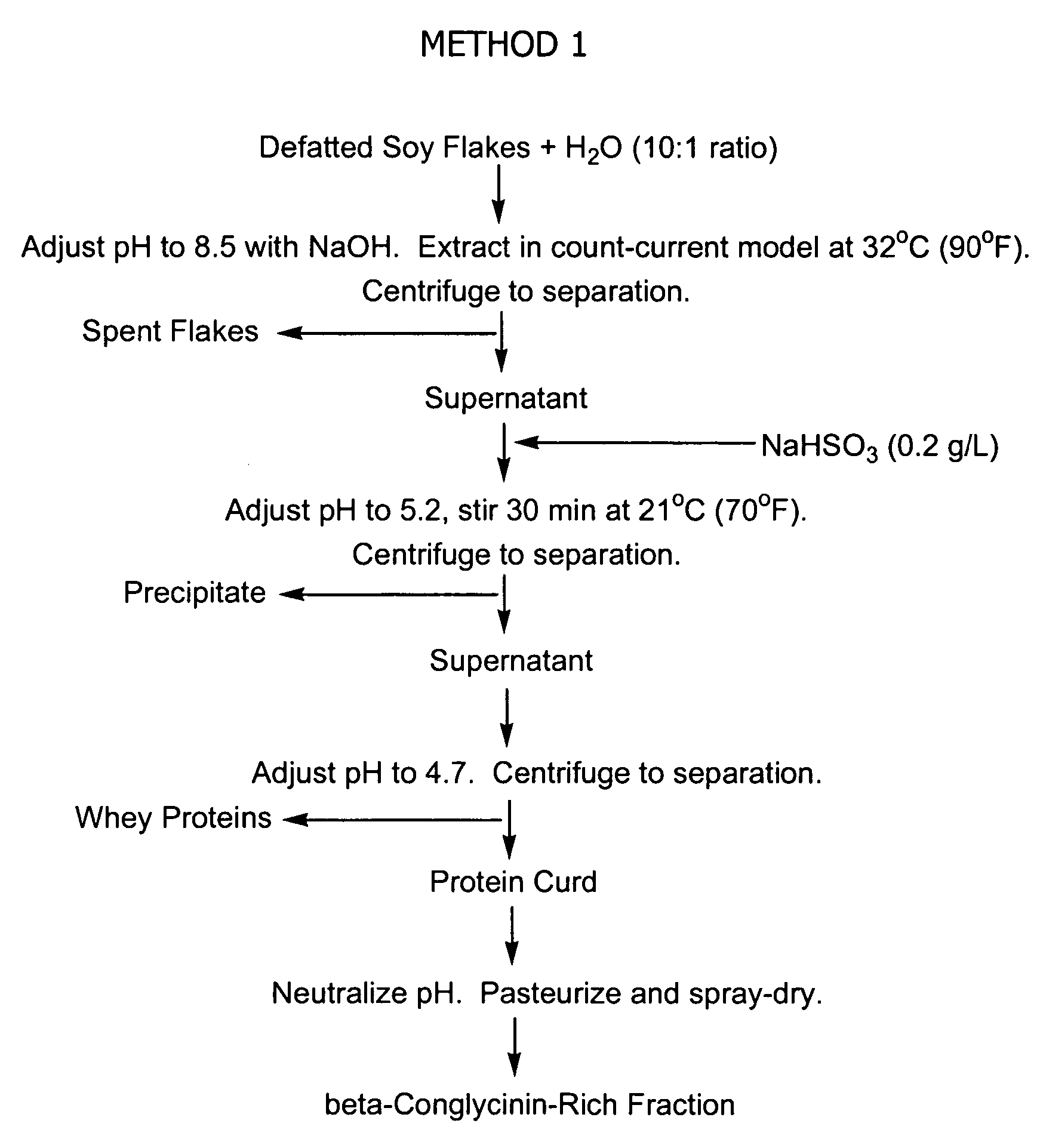

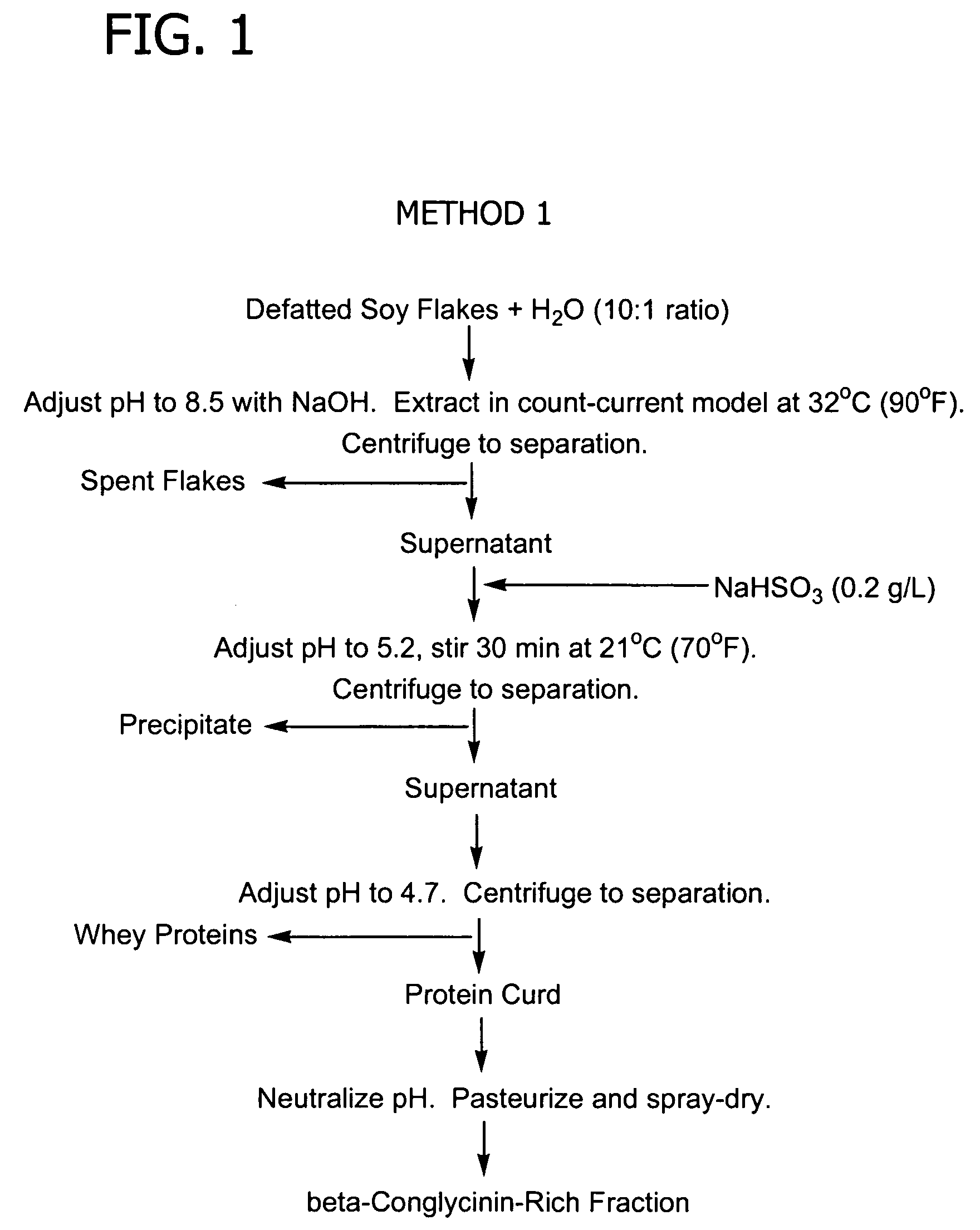

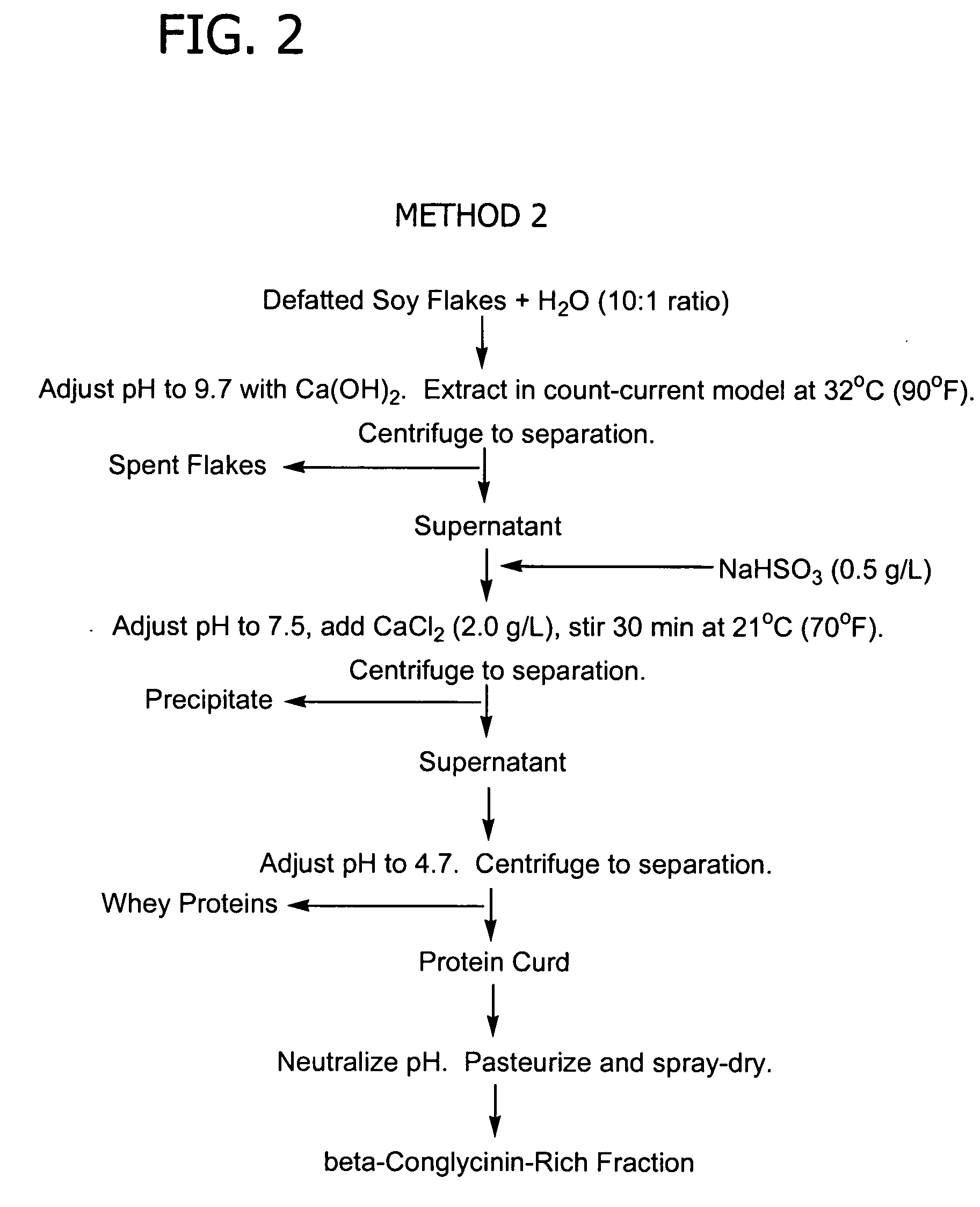

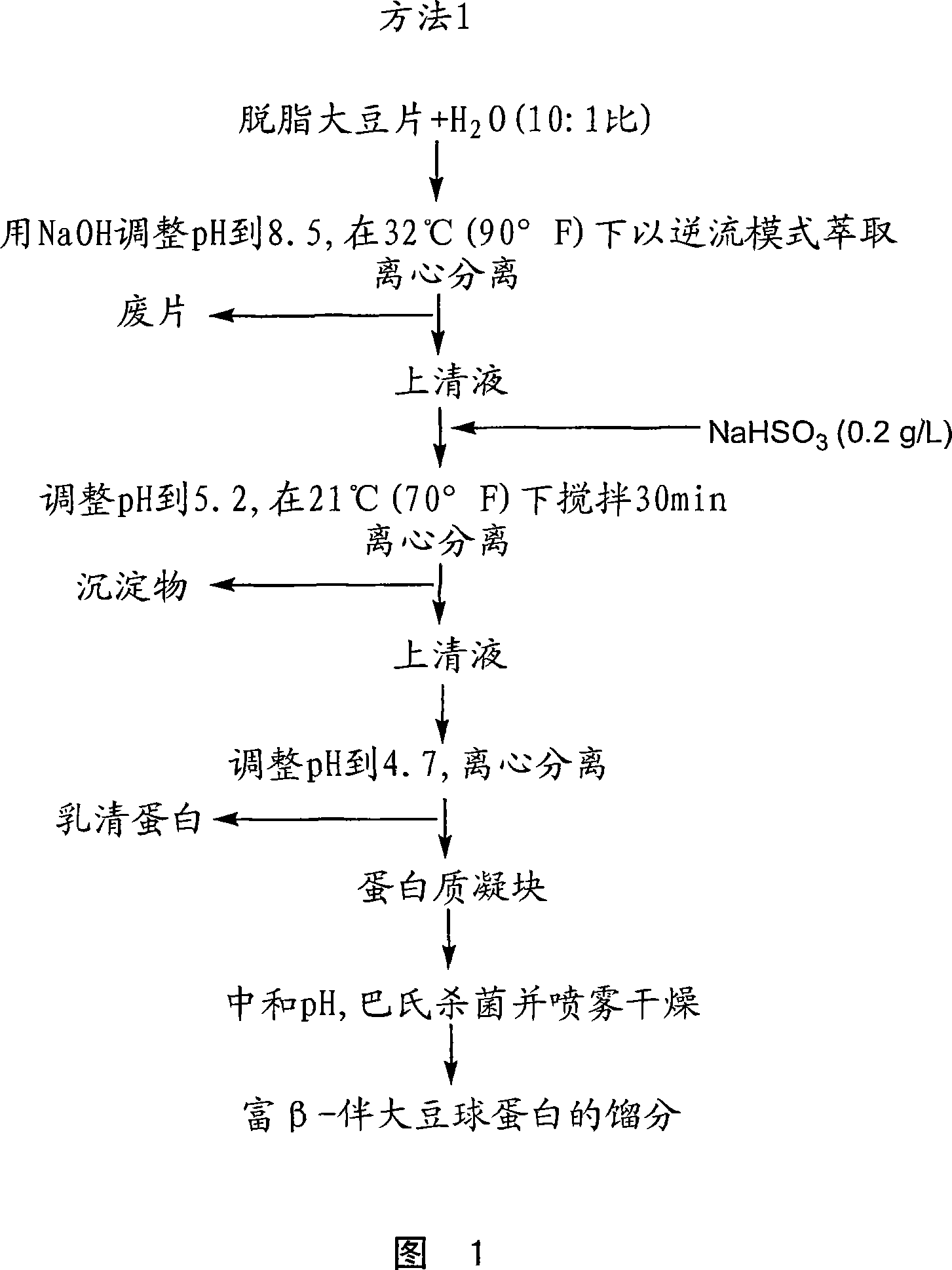

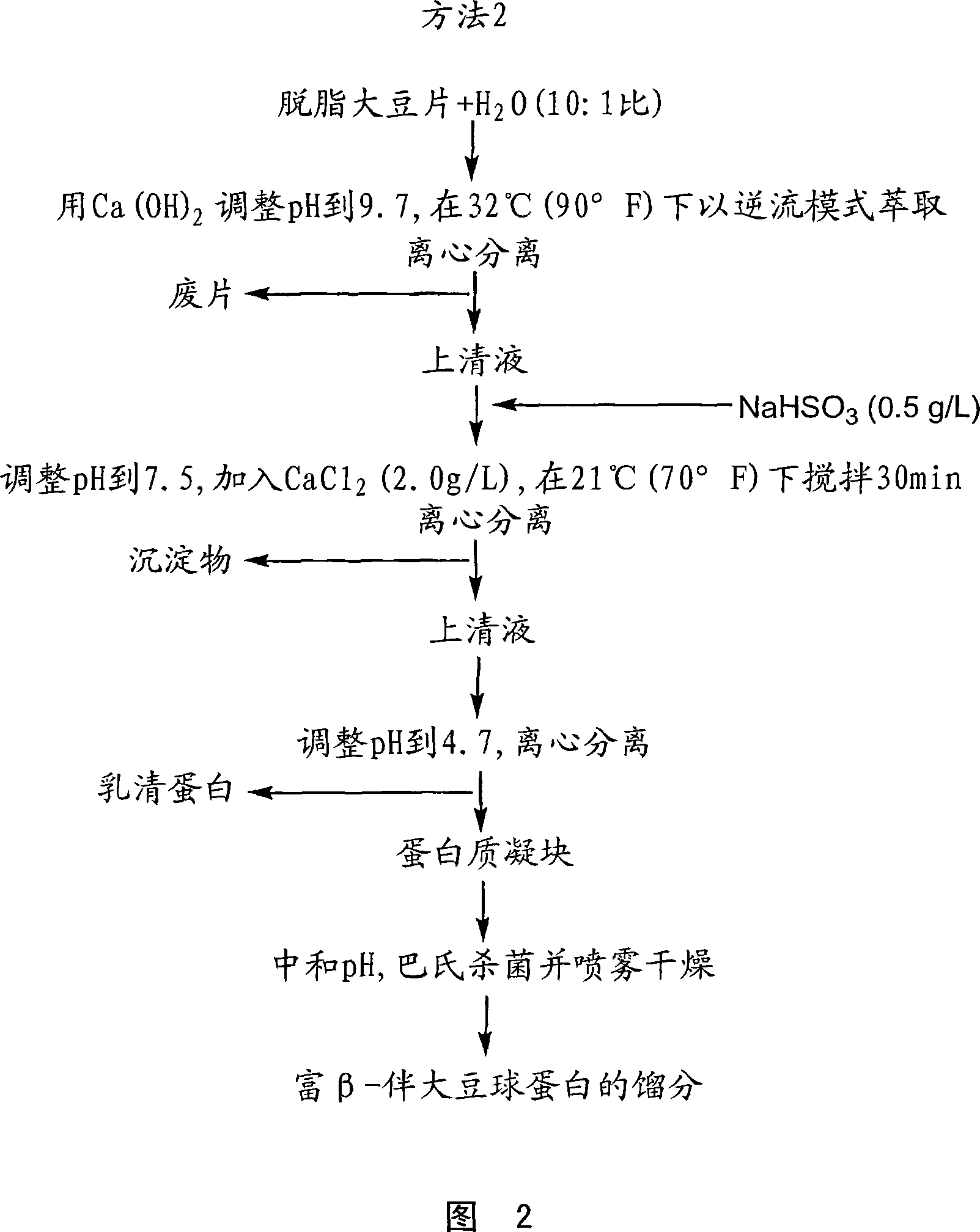

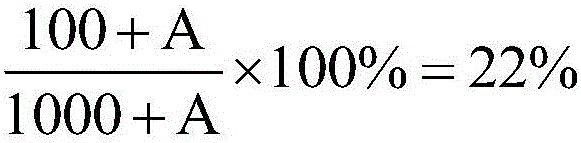

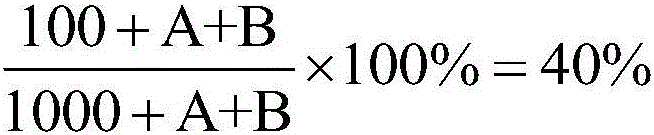

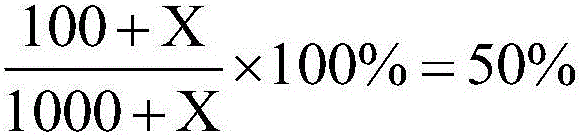

Process for the preparation of glycinin-rich and beta-conglycinin-rich protein fractions

InactiveUS20060057275A1Protein composition from vegetable seedsVegetable proteins working-upAdditive ingredientVegetable Proteins

This invention relates to processes for preparing vegetable protein fractions suitable for use as functional food ingredients, novel vegetable proteins suitable for use as functional food ingredients, and food products containing the novel vegetable protein fractions.

Owner:SOLAE LLC

Fermented soybean meal and production method thereof

InactiveCN106387311AEffective growth controlMaintain biological activityLactobacillusAnimal feeding stuffAntibiotic YDigestion

The invention discloses fermented soybean meal. Based on 100 parts of soybean meal, a fermenting formula comprises the following raw materials of mixed microbial strains, water, an enzyme preparation and a nutritive aid. The invention further discloses a preparation method of the fermented soybean meal. The fermented soybean meal disclosed by the invention has the beneficial effects that according to the fermented soybean meal produced by the method disclosed by the invention, glycinin in the soybean meal can be degraded to 25mg / g or below, beta-conglycinin is degraded to 15mg / g or below, oligosaccharides are completely degraded, trypsin inhibitory factors are degraded to 0.5% or below, the content of lactic acid is 70mg / g or above, and the quality of the fermented soybean meal is obviously improved; and when the fermented soybean meal produced by the method disclosed by the invention is used for feeding animals, digestion and absorption of feeds are facilitated, the digestion and utilization rate of the feeds is increased, the fermented soybean meal can replace animal-derived protein feed raw materials of fish meal and the like, and can wholly or partially replace organic acids and antibiotics, the raising cost is reduced, and economic benefits are increased.

Owner:QINGDAO AGRI UNIV

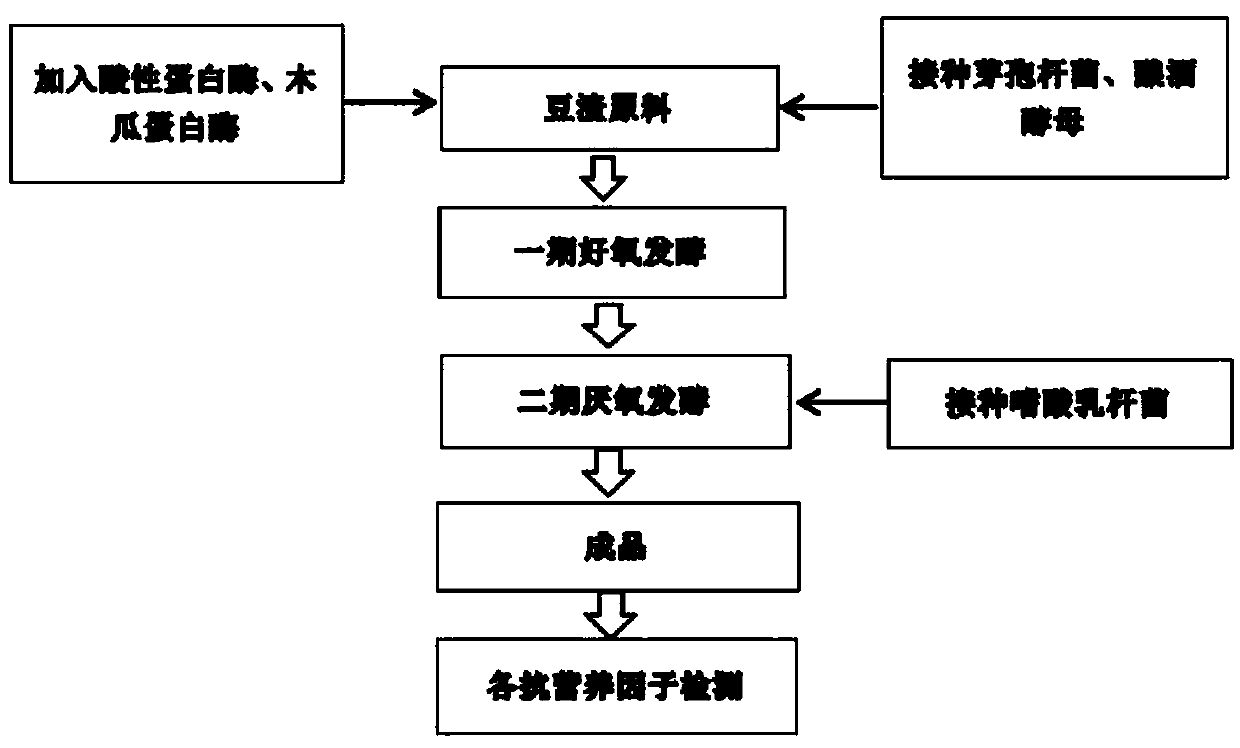

Method for producing fermented soybean meal by two-step inoculation segmented solid-state fermentation

InactiveCN103478417AHigh nutritional valueMeet different needsFungiBacteriaNutritive valuesAnaerobic bacteria

The invention provides a method for producing fermented soybean meal by two-step inoculation segmented solid-state fermentation. The method comprises the following steps of: inoculating the mixed bacterial solution obtained by mixing bacillus subtilis solution, candida mycoderma bacteria solution and lactobacillus solution in peeled soybean meal and performing mixed fermentation; and inoculating the lactobacillus solution in the fermented product, mixing, and performing anaerobic fermentation to obtain the fermented soybean meal. The method is capable of meeting the different needs of aerobic bacteria and anaerobic bacteria, can be used for preparing high-quality fermented soybean meal, and is free of chemical additives; due to the various digestive enzymes, organic acids, medium and small molecular proteins (functional peptides), amino acids, vitamins, probiotics and the like generated during the fermentation process, the nutritive value of the soybean meal is greatly increased; the prepared fermented soybean meal contains not less than 16% of soybean peptide, not more than 25mg / g of glycinin, not more than 20mg / g of beta-conglycinin, not less than 3.5% of lactic acid, and not less than 2*10<9> beneficial viable bacteria; and microbial source nutrients are beneficial to the maintenance of intestinal structure and can promote immunologic function and improve animal production performance.

Owner:宁波中瑞生物科技有限公司

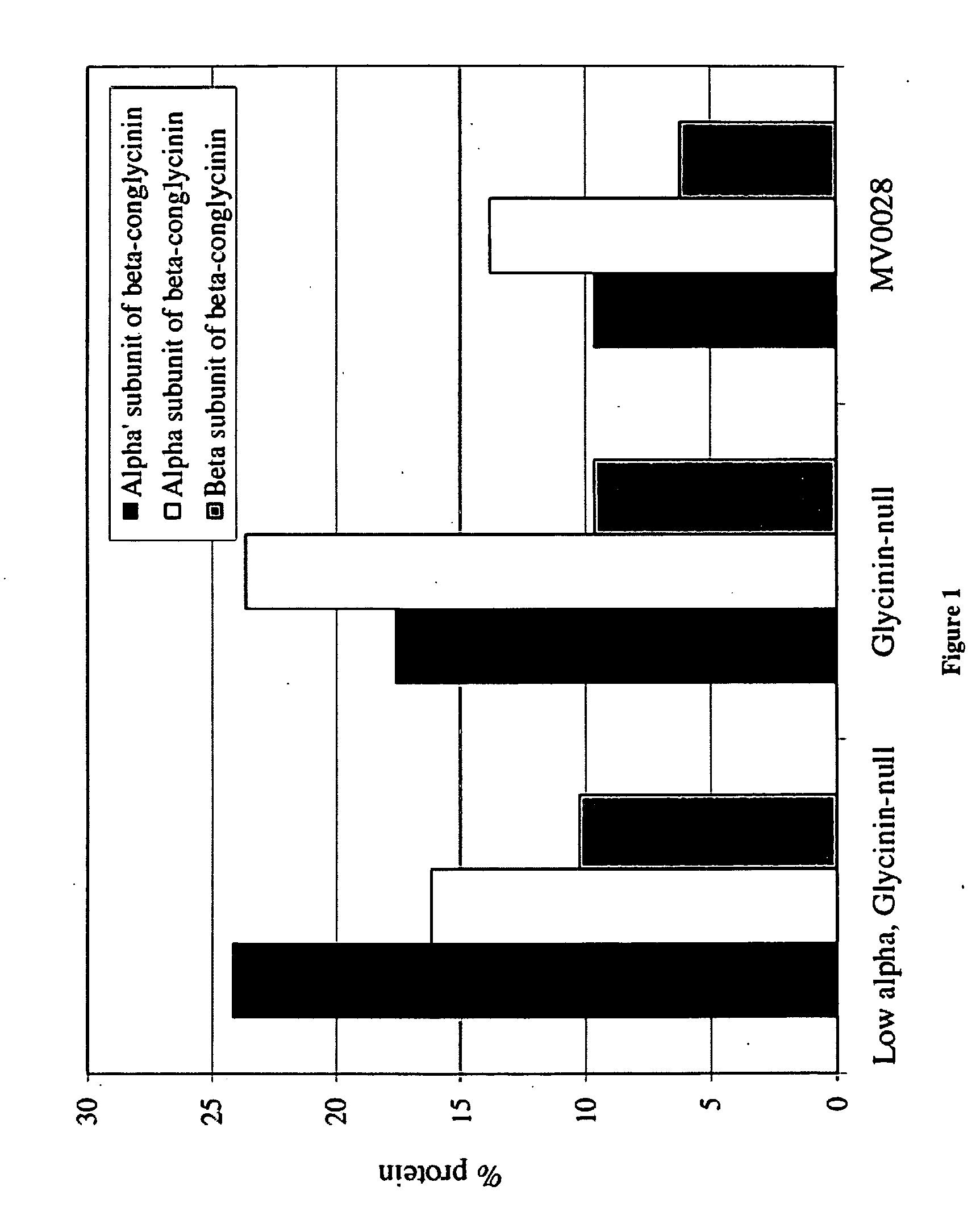

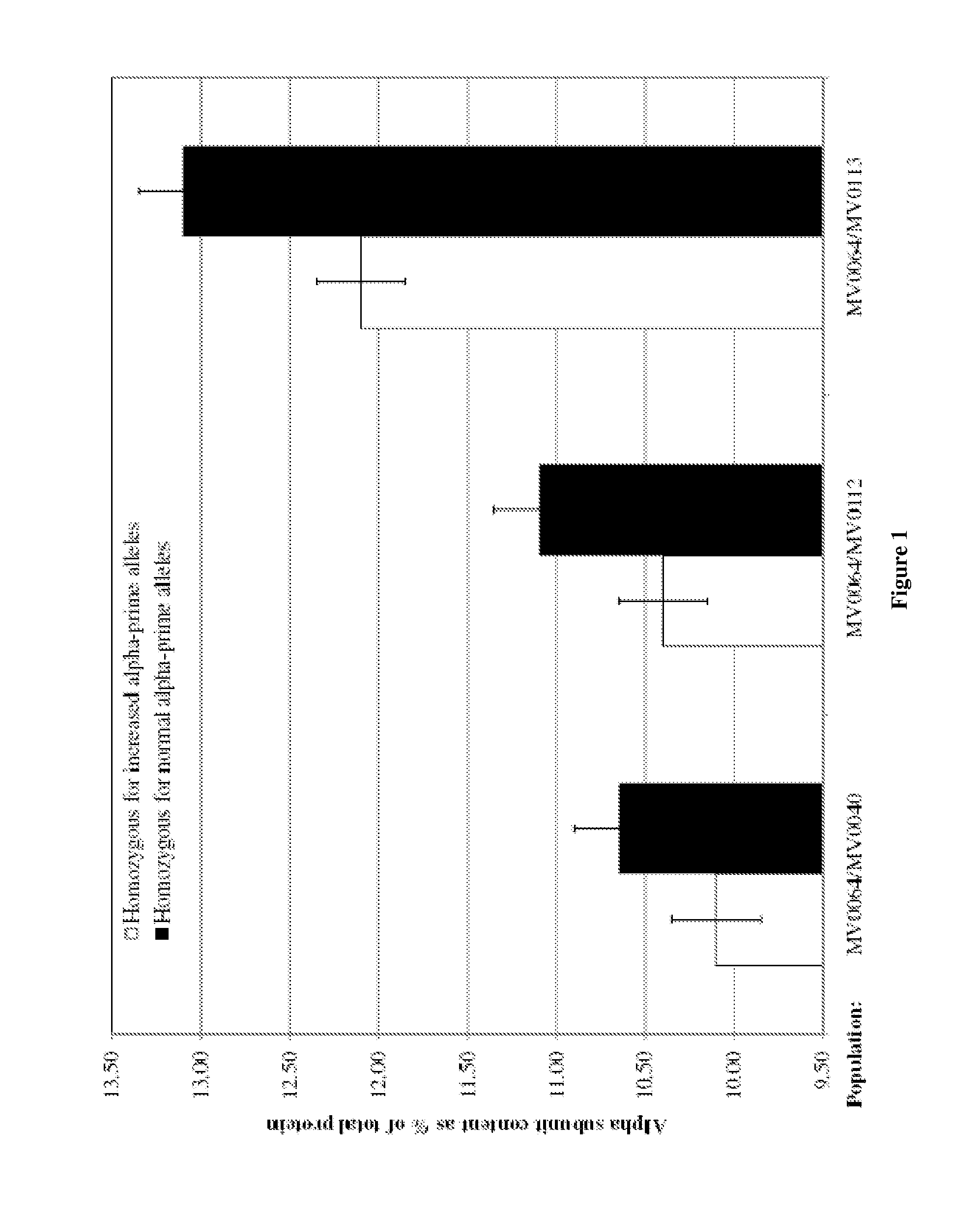

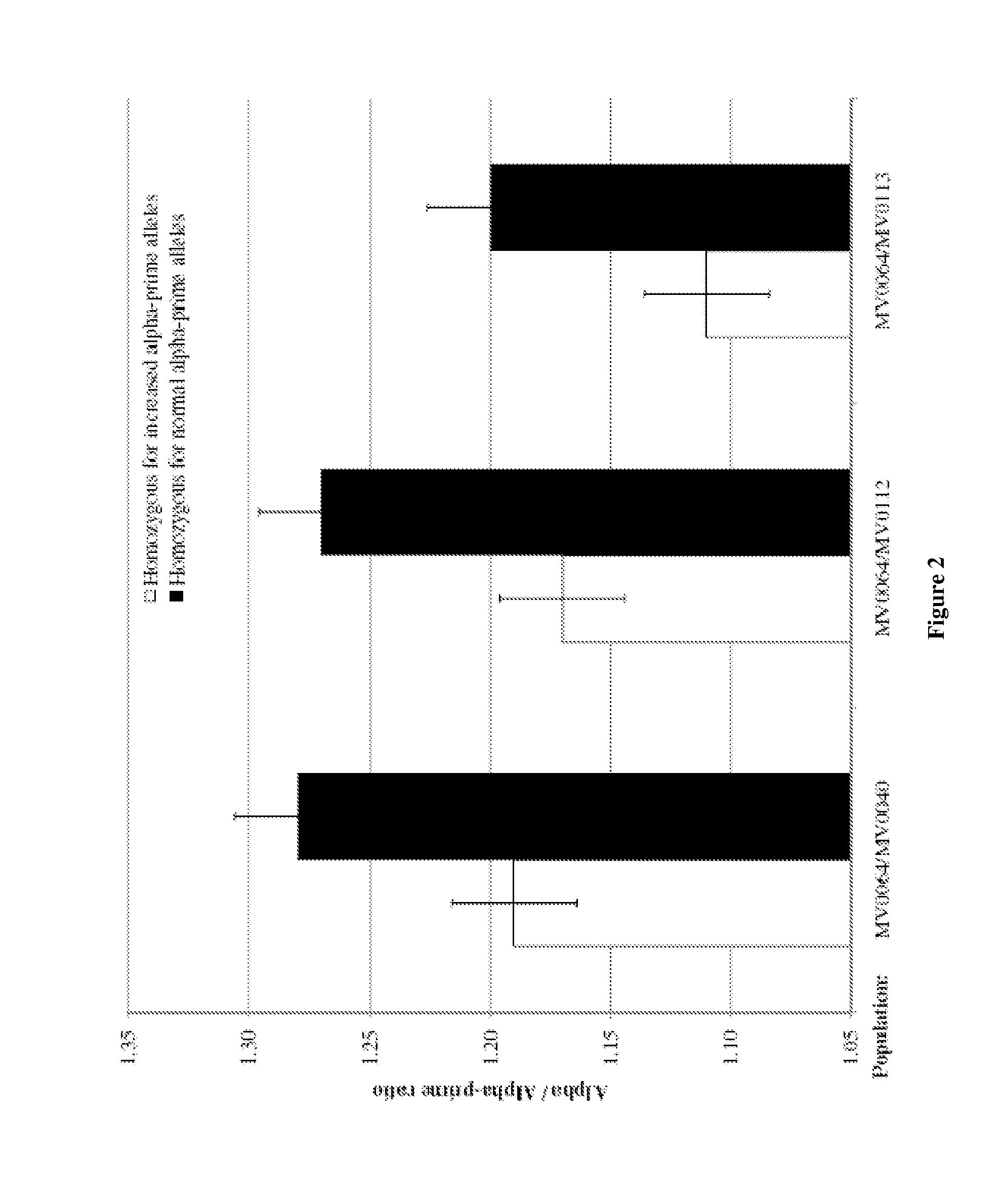

Increased alpha-prime beta-conglycinin soybeans

ActiveUS20090068337A1Increase productionAltered fatty acid compositionImmunoglobulinsFermentationNull phenotypeGlobulin

The invention overcomes the deficiencies of the art by providing a soybean plant with non-transgenic mutations conferring decreased α-subunit of β-conglycinin content and increased α′-subunit content of β-conglycinin in seed. Moreover, the invention provides an agronomically elite soybean plant with non-transgenic mutations conferring a gyclinin null phenotype, increased β-conglycinin content, and increased α′-subunit content of β-conglycinin in the seed. The invention also provides derivatives, and plant parts of these plants and uses thereof. Methods for producing such plants are also provided.

Owner:MONSANTO TECH LLC

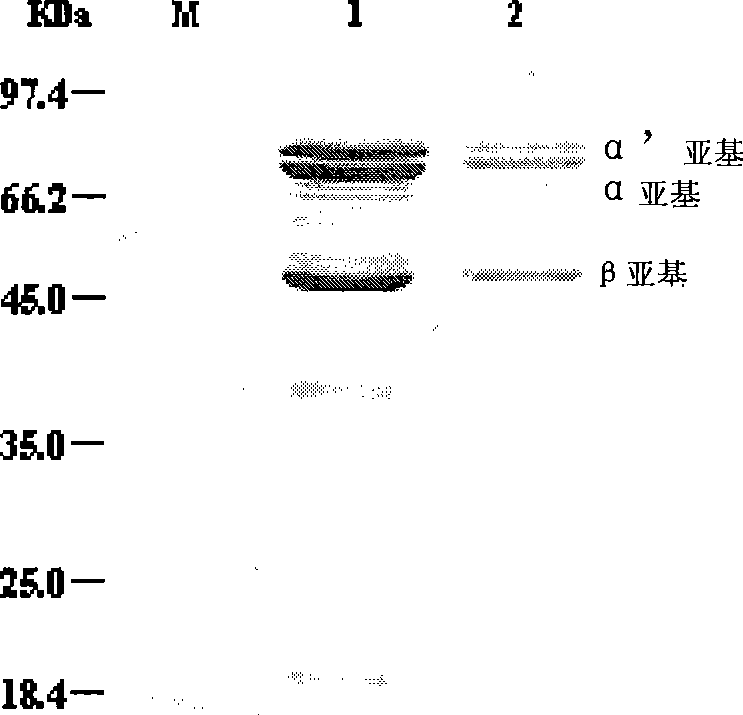

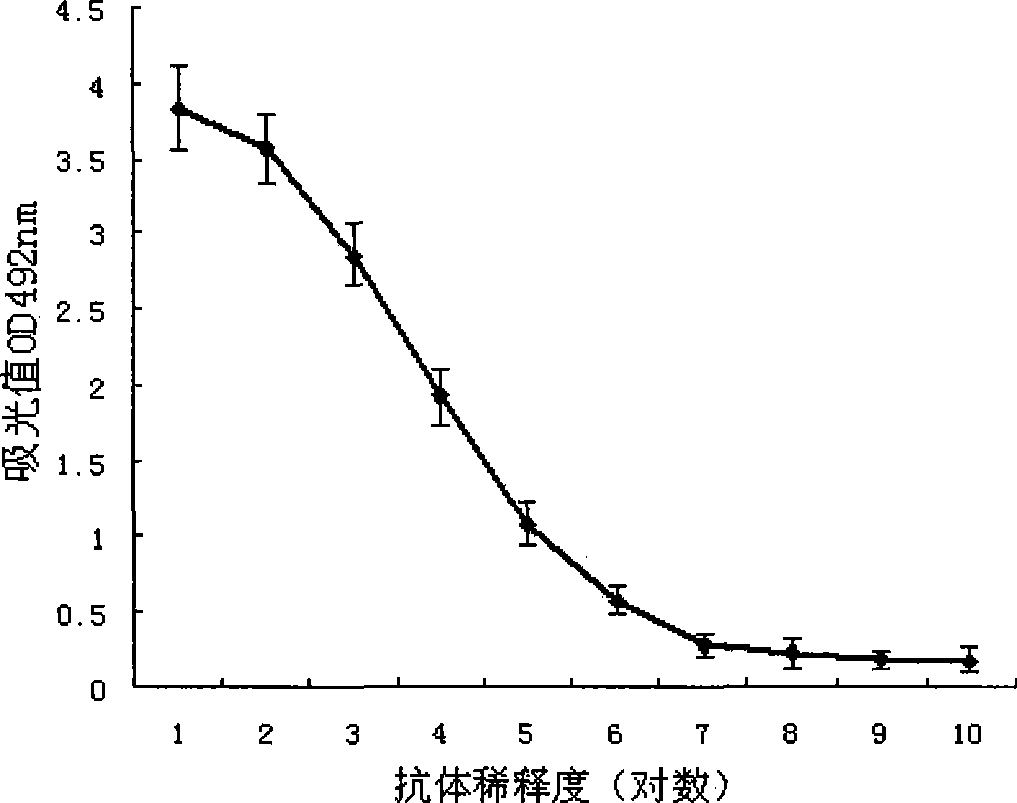

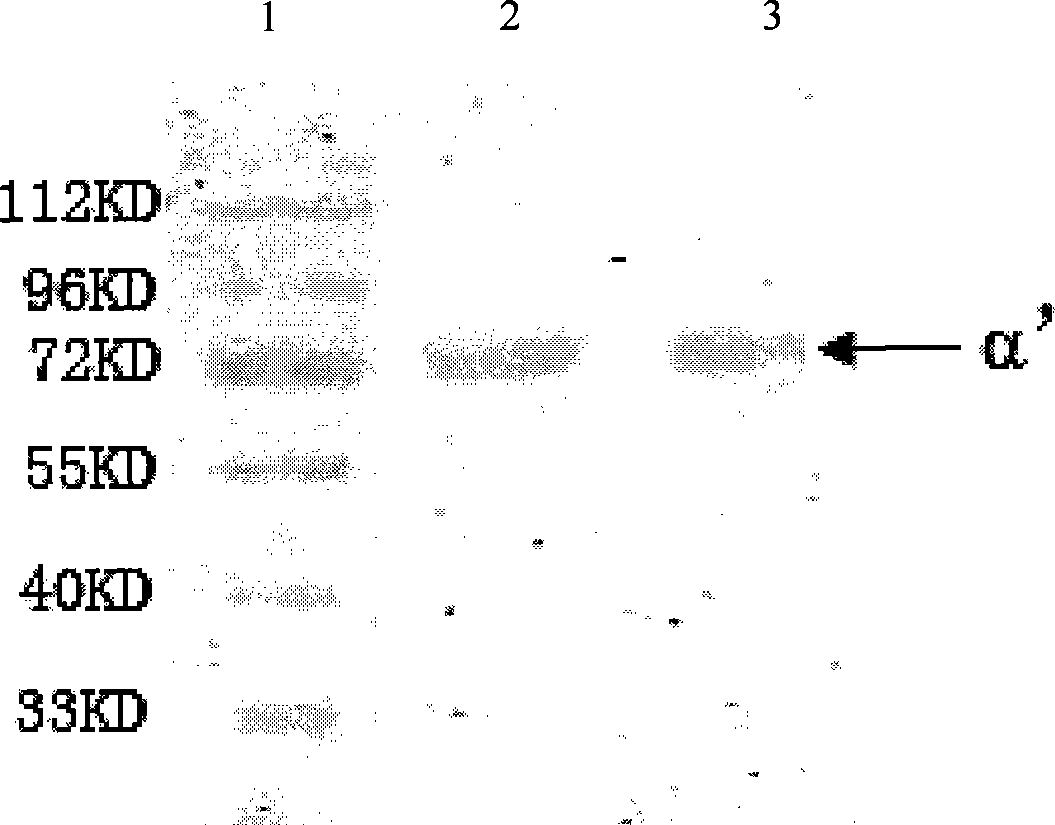

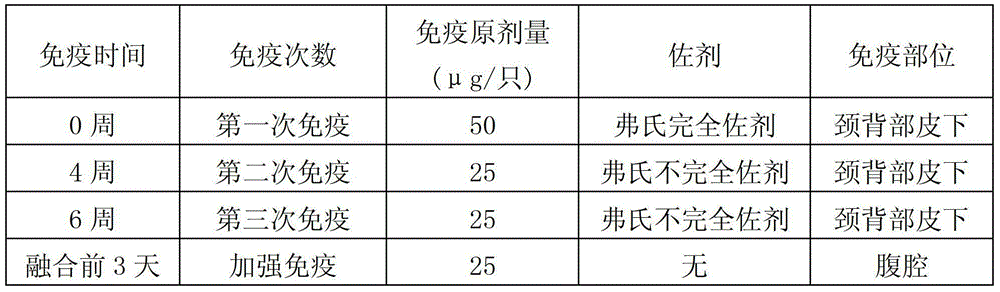

Method for detecting Beta accompany glycinin and specific antibody and reagent kit thereof

ActiveCN101441222AHigh potencyHigh affinityBiological testingForeign genetic material cellsCarrier proteinSpecific antibody

The invention discloses a method for detecting beta conglycinin, the monoclonal antibody special therefor, and the kit. The kit for detecting beta conglycinin comprises beta conglycinin monoclonal antibody or polyclonal antibody, wherein the monoclonal antibody or the polyclonal antibody is obtained with the conjugate of beta conglycinin hapten and carrier protein as immunogen; and the beta conglycinin hapten is the antigen epitope peptide on alpha subunit of beta conglycinin molecule. Experiment proves that the beta conglycinin monoclonal antibody prepared by the invention method has high potency, high affinity, and strong reaction specificity, and can highly bond with the beta conglycinin without cross reaction; and when the monoclonal antibody of the invention is used for detection, itis possible to obtain wide detection range (0.002 mu g / ml-1.000 mu g / ml), high sensitivity (0.002 mu g / ml), and small coefficient of variation. The hybridoma of the invention can stably produce monoclonal antibody, thus the detection method and the monoclonal antibody special therefor of the invention are applicable to the detection of beta conglycinin in grain food, animal feed, and the like.

Owner:北京同力兴科农业科技有限公司

Preparation method for curcumin-loaded nano-emulsion

ActiveCN107028883AHigh encapsulation efficiencyReduce manufacturing costAntibacterial agentsAntimycoticsEnzymatic hydrolysisTG - Triglyceride

The invention provides a preparation method for a curcumin-loaded nano-emulsion, belonging to the technical field of curcumin nano-emulsions. The preparation method provided by the invention overcomes the technical problems of potential safety hazards and high cost of conventional preparation methods for curcumin-loaded nano-emulsions. The preparation method comprises the following steps: 1, subjecting beta-conglycinin to ultrasonic treatment, enzymatic hydrolysis or glycosylation so as to prepare a water phase; and 2, mixing the water phase with an oil phase which is prepared from curcumin and middle-chain triglyceride, carrying out homogenization, and then carrying out treatment in an ultrasonic cell disruptor so as to obtain the curcumin-loaded nano-emulsion. The curcumin-loaded nano-emulsion prepared by using the method in the invention has a high entrapment rate. The method provided by the invention reduces preparation cost and can guarantee that the prepared curcumin-loaded nano-emulsion is healthy, safe and excellent in quality; and the method is more suitable for industrial production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

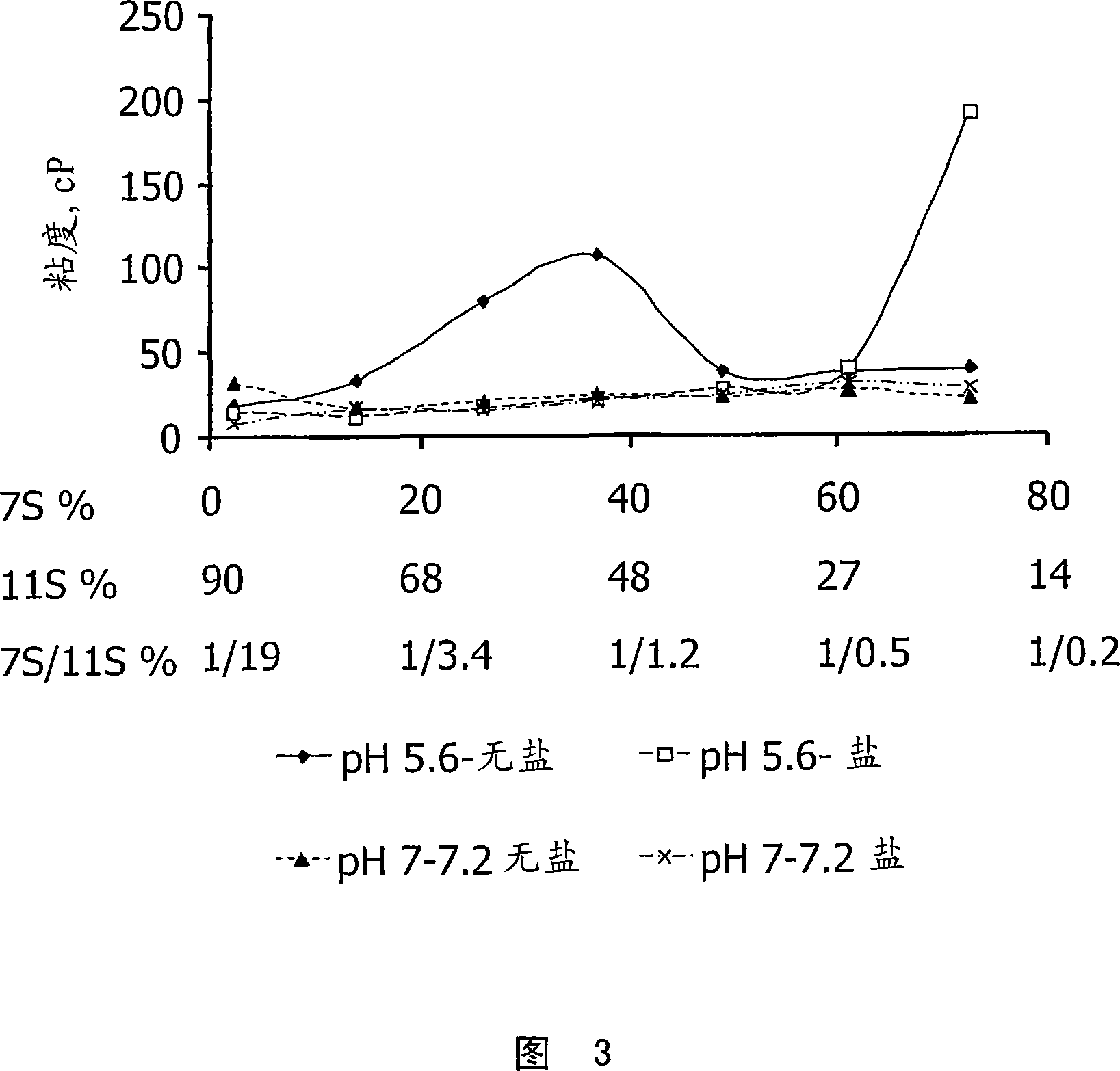

High beta-conglycinin products and their use

InactiveUS7094751B2Improved physical (e.g.Simple methodBiocidePeptide/protein ingredientsProtein compositionAdditive ingredient

Owner:MONSANTO CO (MONSANTO CY)

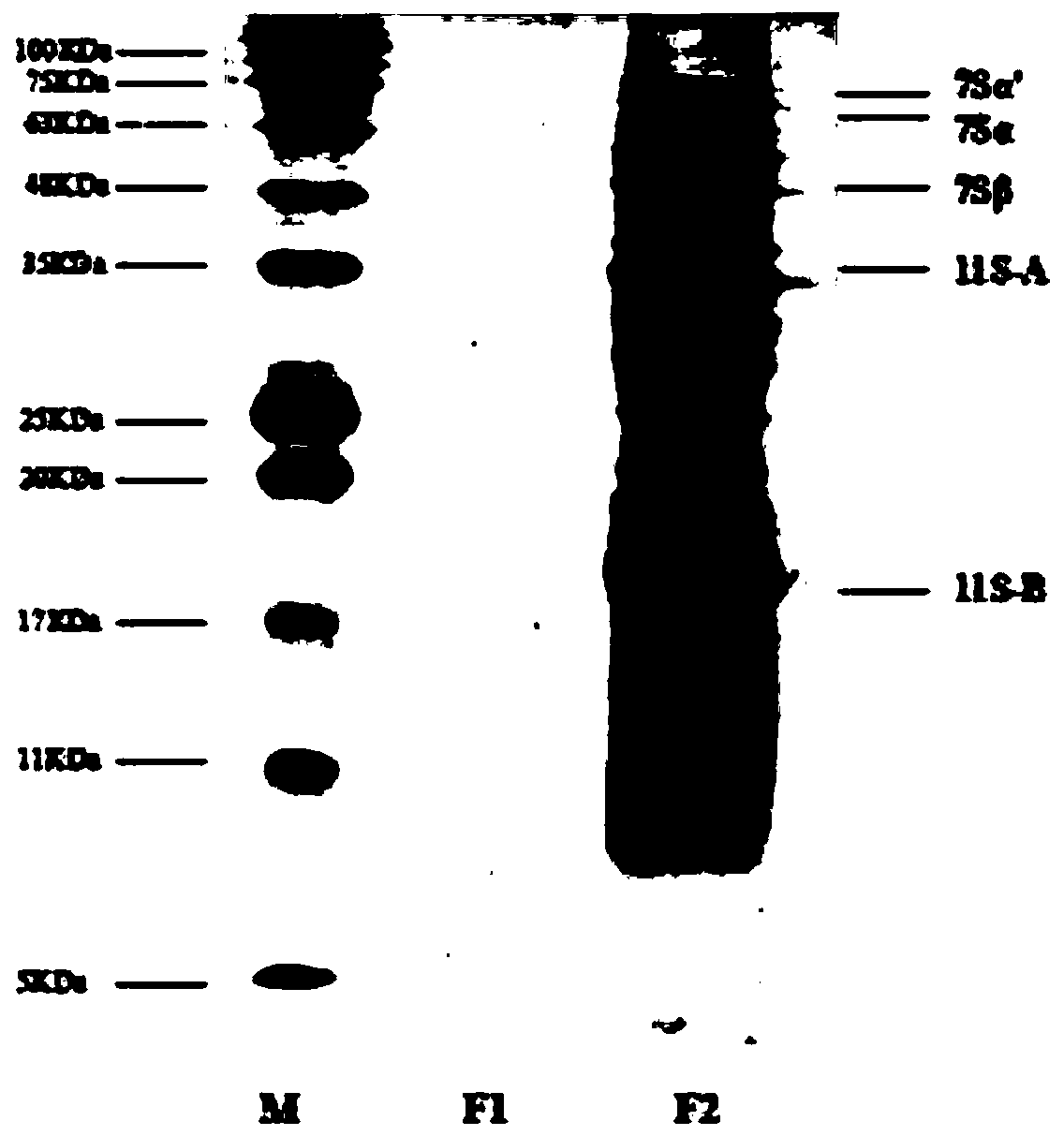

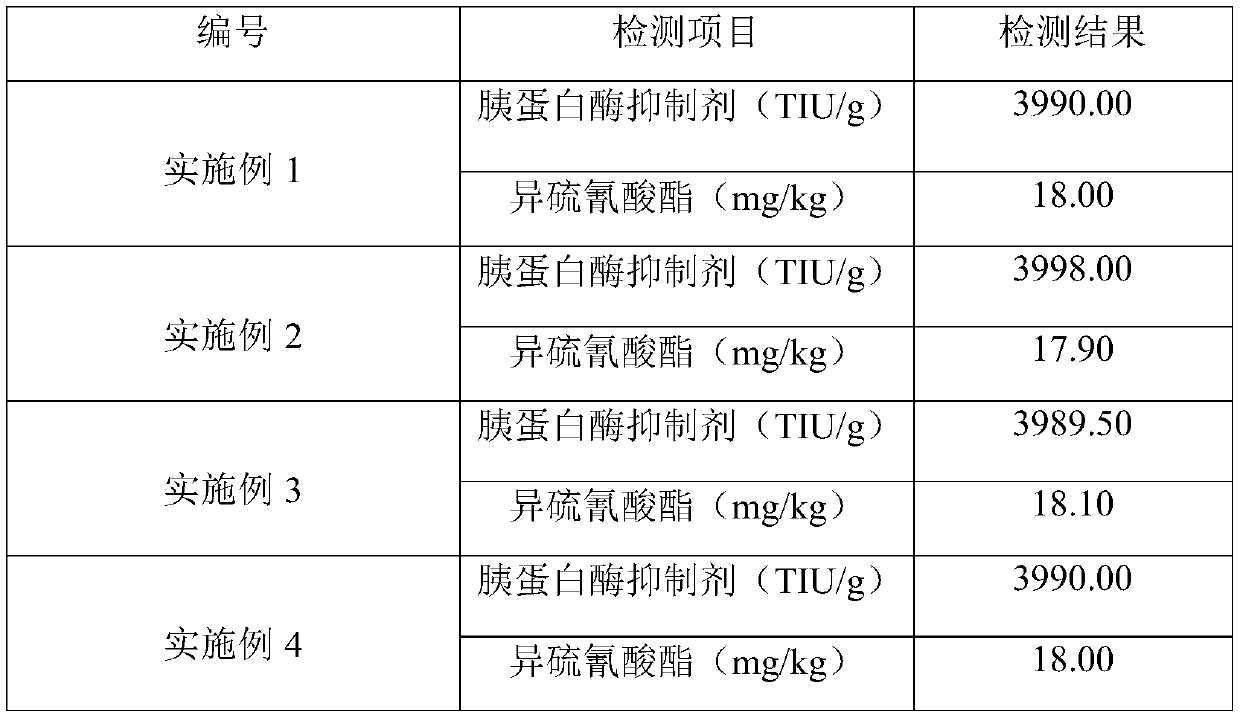

Microbial fermentation method for eliminating anti-nutritional factors in bean dreg feed

The invention belongs to the technical field of biological feeds, and relates to a microbial fermentation method for eliminating anti-nutritional factors in a bean dreg feed. The method comprises the following specific steps: activating strains to respectively obtain a bacillus fermentation seed liquid, a saccharomyces cerevisiae fermentation seed liquid and a lactobacillus acidophilus fermentation seed liquid; mixing bean dregs with bran or rice bran, adding acid protease and papain, performing mixing to obtain a first-stage aerobic fermentation culture medium, performing inoculation with the bacillus fermentation seed liquid and the saccharomyces cerevisiae fermentation seed liquid, and performing first-stage aerobic fermentation to obtain a first-stage fermented mixture; performing inoculation with the lactobacillus acidophilus fermentation seed liquid to obtain a second-stage fermentation mixture; and carrying out second-stage anaerobic fermentation under a sealed condition so as to obtain a finished product. The anti-nutritional factors of the bean dreg feed treated by the method such as antigen proteins including trypsin inhibitor, glycinin (11S), beta-conglycinin (7S) and the like and isothiocyanate are obviously reduced or completely removed; and the method is simple and convenient to operate, has high economic benefit and is suitable for large-scale popularization and production.

Owner:JIANGSU UNIV

High beta-conglycinin products and their use

InactiveUS20060100133A1Improved physical (e.g.Simple methodPeptide/protein ingredientsFrozen sweetsAdditive ingredientProtein aggregation

The utility of soybeans having a composition of greater than 40% of the protein as beta-conglycinin and less than 10% of the protein as glycinin for making highly functional high beta-conglycinin compositions was discovered. The discovered ingredients are useful for mimicking the texturizing properties of casein while also maintaining or improving physiological benefits of soy protein ingredients (e.g., cholesterol and triglyceride lowering properties). The high stability of the high beta-conglycinin compositions against protein-protein aggregation reactions is valuable for creating good tasting beverages and beverage mixes. Cheese with good spreadability, gloss and smoothness was made using an enzyme-modified version of the new ingredient composition. Cheese with good firmness and meltability was also created using a different enzyme-treatment High beta-conglycinin compositions were found to demonstrate excellent emulsifying and gelling properties in the pH region (5.5-6.2) relevant to meet applications. High beta-conglycinin compositions also have possible use for improving the composition of essential amino acids for infant humans and animals.

Owner:MONSANTO TECH LLC

Hypoallergenic transgenic soybeans

InactiveUS20050015826A1Fatty acid hydrogenationFatty acid esterificationGlycineGenetically modified soybean

Hypoallergenic transgenic soybeans and recombinant expression constructs to lower soybean vacuolar protein, commonly know as P34, as well as other allergens are disclosed. Soybean protein products made from these hypoallergenic soybeans should be substantially free of the major soy allergen, P34, and, in addition, other minor soy allergens, such as, Gly m Bd 28K, alpha-subunit of beta-conglycinin, KSTI, Gly m2, Gly m IA, Gly m IB, rGLY m3 and glycinin G1.

Owner:KINNEY ANTHONY +1

Methods and Compositions for Increased Alpha-Prime Beta-Conglycinin Soybeans

InactiveUS20110252490A1Increase productionEnhanced animalLibrary screeningGenetic engineeringGermplasmBreeding program

The invention concerns methods for breeding soybean plants containing genomic regions associated with increased α′-subunit of β-conglycinin content in seed. Moreover, the invention provides germplasm and the use of germplasm containing genomic regions conferring increased α′-subunit of β-conglycinin content for introgression into elite germplasm in a breeding program. The invention also provides derivatives, and plant parts of these plants and uses thereof.

Owner:MONSANTO TECH LLC

Proteases

Disclosed is a thermostable protease congenetic with the protease from Nocardiopsis and the preparation in the wild type reconstructed host-cells which contain the transgenic plant and the no-human transgenic animal cells. The protease is effective in animal feed, in particular to fish feed and washing agent. The protease can degrade soybean Bowman-Birk stayer, other anti-nutritional factors such as soybean agglutinin and Kunitz trypsinase stayer, and separated soybean storage protein, glycinin and beta-conglycinin. The structural characteristics related to the thermostability of the proteases of the peptidase family S2A or S1E.

Owner:NOVOZYMES AS

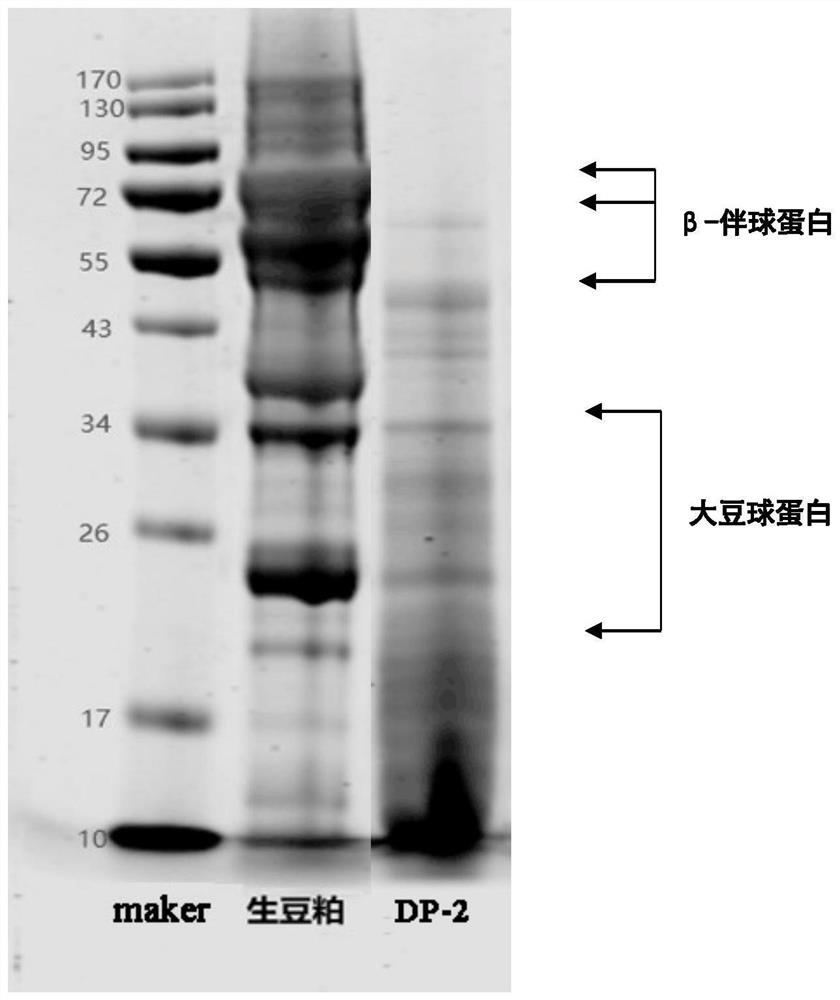

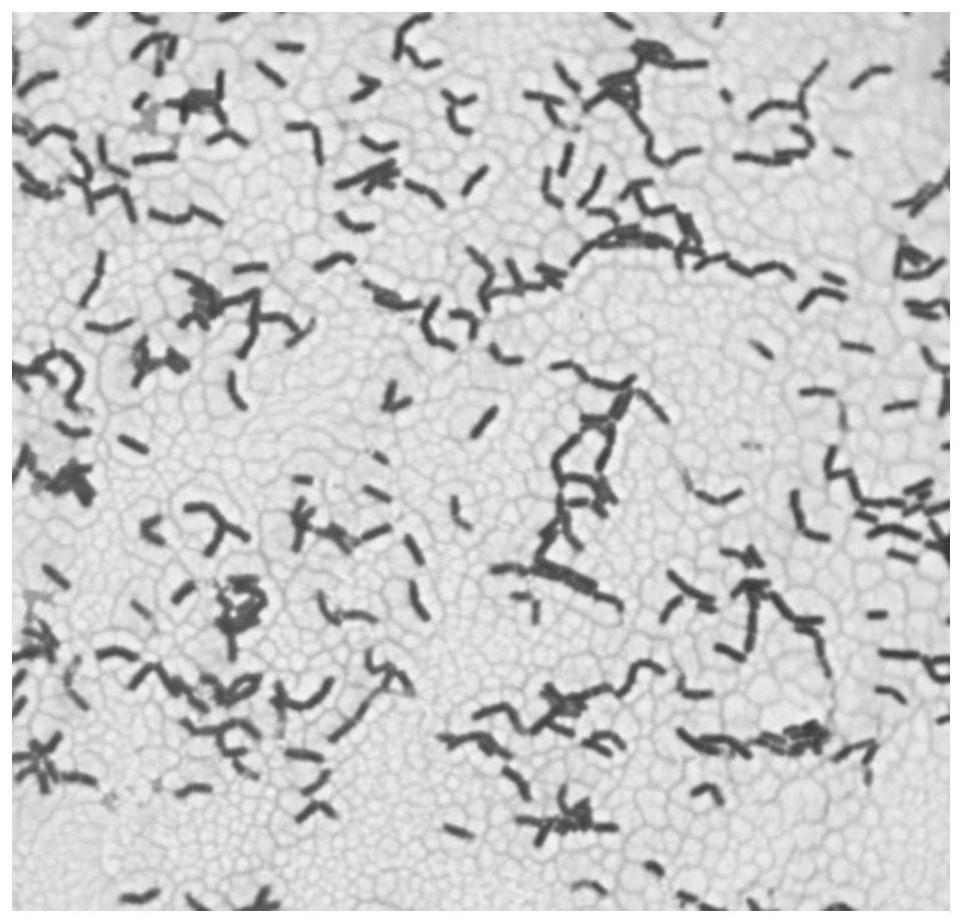

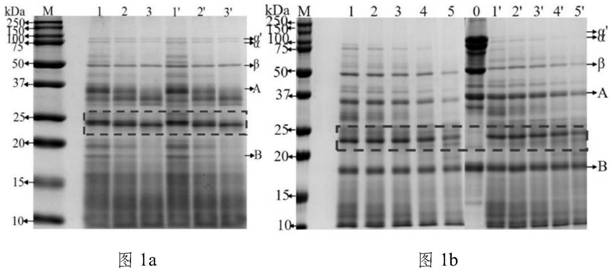

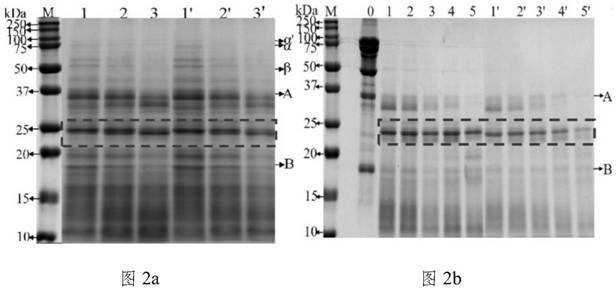

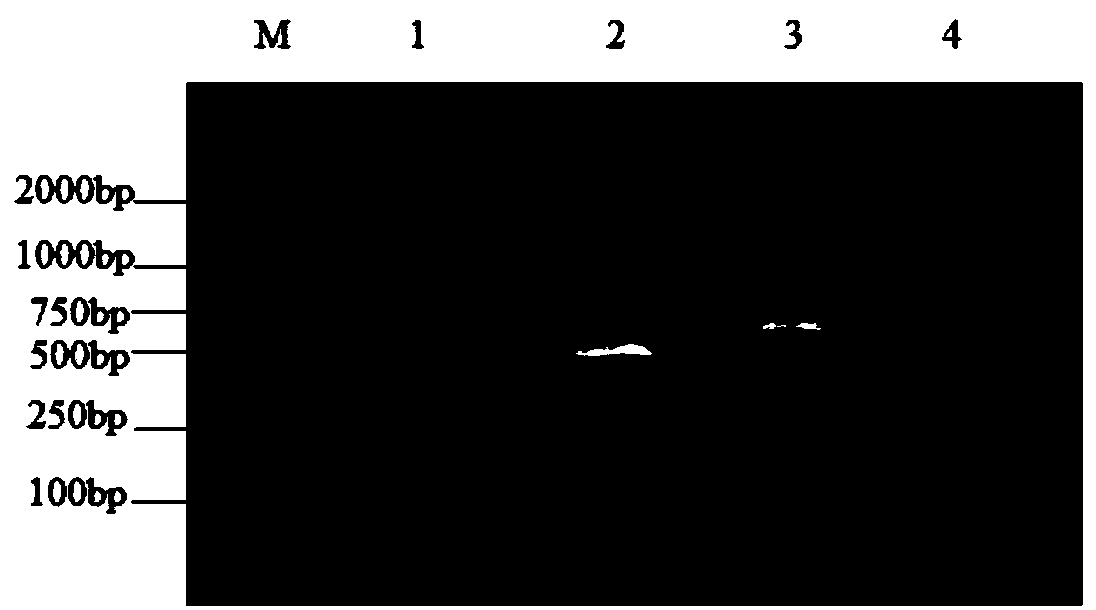

Bacillus velezensis strain for soybean meal fermentation

ActiveCN111826295AHigh alkalinityHigh neutral proteaseBacteriaFood processingBiotechnologyAnti nutrients

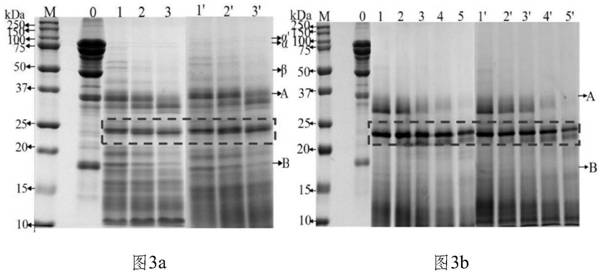

The invention belongs to the field of bacteria / livestock microorganisms, and particularly relates to a bacillus velezensis strain for soybean meal fermentation. The strain is bacillus velezensis DP-2with a preservation number of CGMCC No.17235. The bacillus velezensis strain DP-2 can efficiently secrete neutral protease and alkaline protease, and has a good degradation effect on anti-nutrient substances such as glycinin and beta-conglycinin in soybean meal; and the degradation rate of the glycinin can reach 81%-96%, the degradation rate of the beta-conglycinin can reach 50%-67%, acid-solubleprotein is increased by 5-6 times, the content of nutrient substances in fermented soybean meal can be remarkably increased, the nutrient utilization rate is remarkably increased, and therefore the nutritional value of the soybean meal is improved.

Owner:CHONGQING ACAD OF ANIMAL SCI

Indirect ELISA (enzyme linked immunosorbent assay) method for detecting soybean antigenic protein serum antibody

The invention discloses an indirect ELISA (enzyme linked immunosorbent assay) method for detecting soybean antigenic protein serum antibody. The indirect ELISA method includes using purified soybean antigenic protein as antigenic peridium to detect soybean antigenic protein serum antibody. The soybean antigenic protein comprises glycinin and beta-conglycinin. The indirect ELISA method has the advantages that the method has high sensitivity and specificity to allergic diseases, which are caused by the soybean antigenic protein, of humans and animals, a basis is provided for diagnosis of the diseases, soybean protein source food allergy of animals in our country is convenient to overcome, effective technical means is provided for disease research of the diseases, and the quick and simple detecting method is provided for mastering prevention and morbidity of the soybean antigenic protein allergic diseases in humans and animals.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Method for efficiently digesting antinutritional factors and antigen proteins in animal-breeding soybean meal by acetic acid method

PendingCN106666335AQuality improvementImprove use valueFood processingAnimal feeding stuffAntigenAcetic acid

The invention discloses a method for efficiently digesting antinutritional factors and antigen proteins in animal-breeding soybean meal by an acetic acid method. The soybean meal is the most widely-used plant protein raw material in the feed industry, but a variety of antinutritional factors and antigen proteins exist in the soybean meal, and must be destroyed by certain processing before the soybean meal is used for breeding animals. According to the method, acetic acid with a certain concentration is used for rapidly treating the soybean meal under a heating condition, so that two typical antigen proteins, namely glycinin and beta-conglycinin, can be completely digested, the content of trypsin inhibiting factors is reduced from 9.5mg / g to 0.3mg / g, and the digestion rate reaches 96% or above. By the method, an effective, simple, convenient and rapid production technology is provided for significantly increasing the nutritional value of the soybean meal and improving the breeding efficiency.

Owner:NANJING FORESTRY UNIV

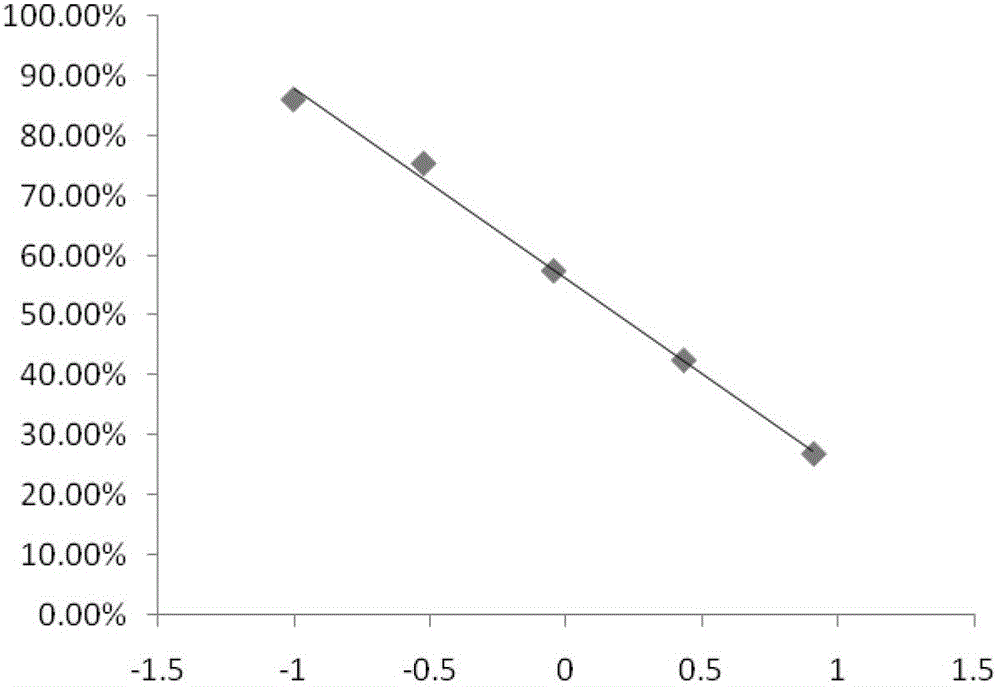

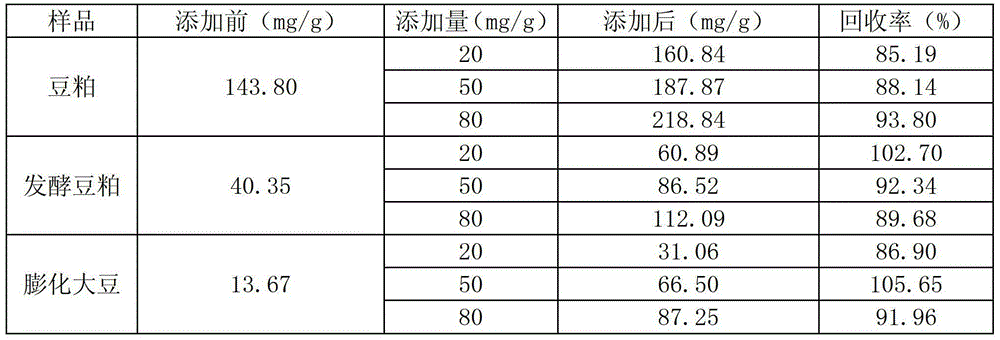

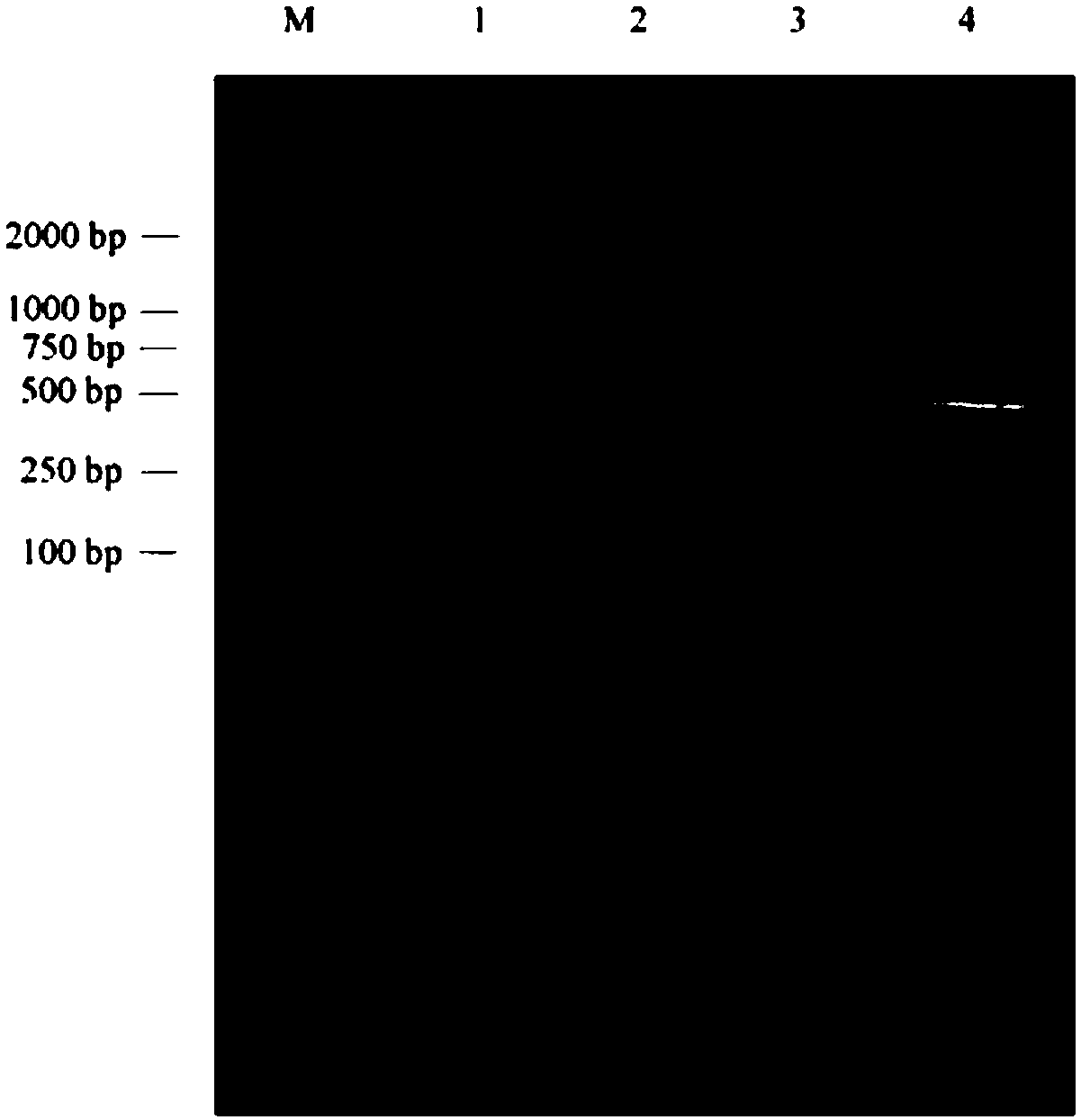

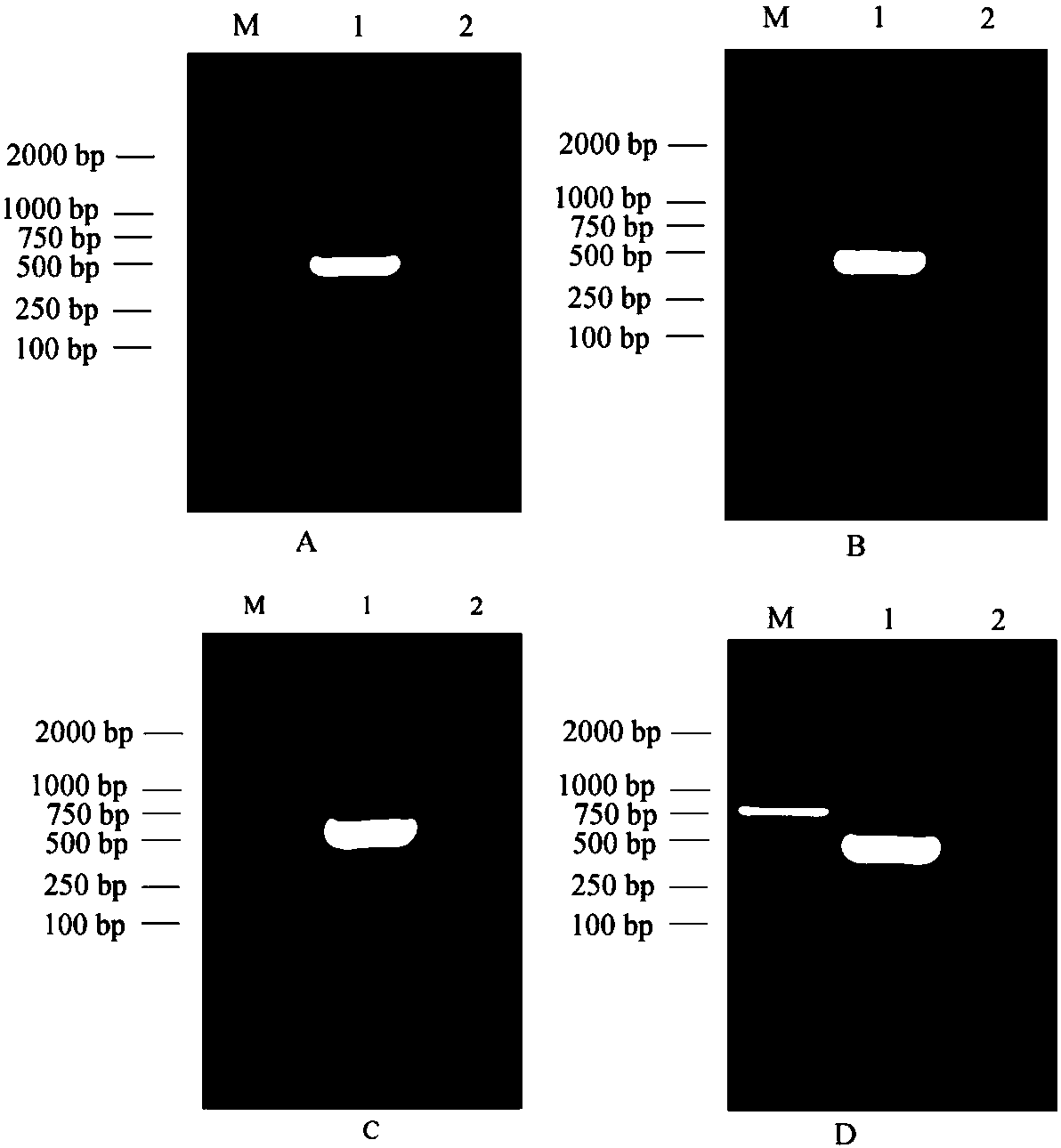

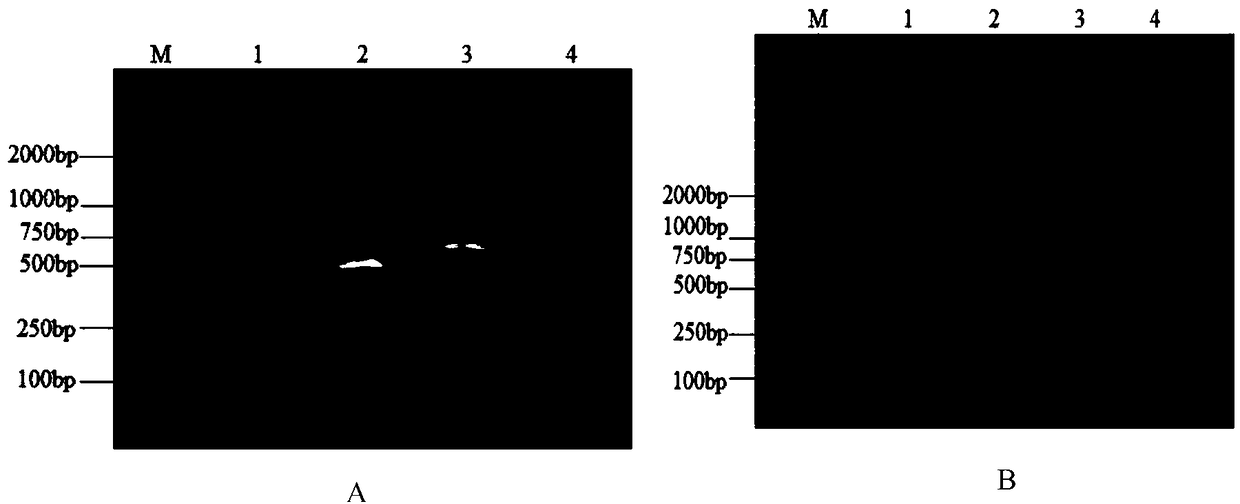

Anti-beta-conglycinin monoclonal antibody and application thereof

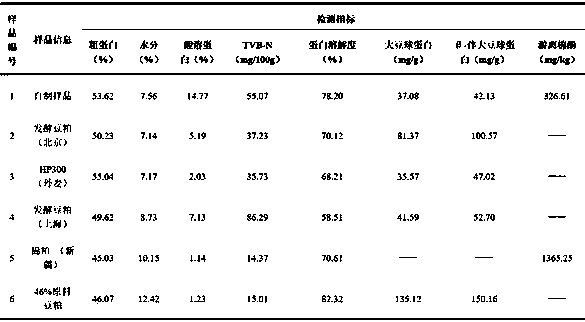

ActiveCN103333862ALow detection limitWide detection rangeOther chemical processesImmunoglobulins against plantsProtein.monoclonalSoybean product

The invention discloses an anti-beta-conglycinin monoclonal antibody and an application of the monoclonal antibody. The monoclonal antibody is secreted by a hybridoma cell strain 2C4CGMCC No.7109; experiments prove that the affinity constant of the beta-conglycinin monoclonal antibody reaches 6.2*10<11>L / mol, the beta-conglycinin monoclonal antibody is applied to detecting beta-conglycinin by means of a competitive ELISA (Enzyme Linked Immunosorbent Assay) for antibody detection, and the detection limit is 0.1ng / ml-8.1ng / mol. The beta-conglycinin monoclonal antibody, a detection method using the monoclonal antibody and a kit with the monoclonal antibody provided by the invention have the advantages of low detection limit, wide detection range, high efficiency, and accuracy, and can be widely applied to the qualitative and quantitative detection of the beta-conglycinin in soybean and a soybean product.

Owner:北京龙科方舟生物工程技术有限公司

Positioned processed and damaged Gly m Bd 60K protein antigen region based on phage display technology and screening method

InactiveCN108329384AQuick checkBiological material analysisPlant peptidesScreening methodBeta-conglycinin

The invention discloses a positioned processed and damaged Gly m Bd 60K protein antigen region based on a phage display technology and a screening method. An amino acid sequence of the antigen regionis shown in SEQ ID NO.16. The method utilizes a series of bioinformatics software and refers to a three-dimensional crystal structure of analyzed beta-conglycinin in a PDB database, studies the processed and damaged Gly m Bd 60K protein antigen region by the phage display technology, and performs accurate positioning on the region where antigenicity of a Gly m Bd 60K protein is reduced due to different processing methods through presenting the Gly m Bd 60K protein and an overlapping protein of the Gly m Bd 60K protein on the surface of a phage. The method provided by the invention provides a theoretical basis for processing method screening in the food industry, and an application product for rapidly detecting a desensitization effect of processed food can be further developed.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for detecting soybean antigen beta-conglycinin

InactiveCN104897902AImprove detection efficiencyEasy to handleBiological testingSimple sampleElisa method

The invention discloses a method for detecting soybean antigen beta-conglycinin. A direct ELISA method for detecting soybean antigen beta-conglycinin is established. The envelope antigen is determined to be 1mu g / mL by virtue of a square matrix experiment, the optimal dilution degree of the antibody is 1:400, the optimal confinement time is determined to be 58.31 minutes by virtue of the orthogonal response surface experiment design, the optimal reaction time of an enzyme-labeled antibody is 139.16 minutes, the optimal reaction time of substrate solution action is 19.43 minutes, the sensitivity is 1ug / ml, and the linear detection range is between 20ng / ml and 640ng / ml. The mean number of the variation coefficient (CV%) between the plates is 8.16 percent, the mean number of the variation coefficient (CV%) in the plates is 6.91 percent, and the cross reaction is smaller than 20 percent. The detection method disclosed by the invention has the characteristics of relatively simple sample pretreatment, rapidness, low cost, low instrumentation degree, short time consumption and the like, can be applied for detecting the content of glycinin in soybean and deep processing products and is applied to field monitoring and large-scale sample screening.

Owner:JILIN AGRICULTURAL UNIV

Glycinin-rich and beta-conglycinin-rich protein fractions

InactiveCN101060790AProtein composition from vegetable seedsVegetable proteins working-upAdditive ingredientVegetable Proteins

This invention relates to processes for preparing vegetable protein fractions suitable for use as functional food ingredients, novel vegetable proteins suitable for use as functional food ingredients, and food products containing the novel vegetable protein fractions. In one embodiment the protein fraction comprises from 40% to 80% by weight ss-conglycinin. In another embodiment the protein fraction comprises 50% to 95% by weight glycinin.

Owner:SOLAE LLC

Method for eliminating beta-conglycinin in fermented soybean meal

ActiveCN106418127AReduce contentImprove product qualityAnimal feeding stuffFood scienceFermentationMoisture

The invention relates to a method for eliminating beta-conglycinin in fermented soybean meal. The method comprises the following steps: (1) regulating the moisture content of soybean meal to be 20-25% (weight ratio); (2) treating the soybean meal obtained in the step (1) by using steam at a temperature of 110-125 DEG C, discharging, and cooling; (3) inoculating saccharomycetes and enterococcus faecium to the soybean meal obtained in the step (2), and regulating the moisture content of the inoculated materials to be 38-42% (weight ratio); (4) performing anaerobic fermentation on the soybean meal obtained in the step (3). According to the method disclosed by the invention, the content of the beta-conglycinin in the fermented soybean meal can be obviously reduced, and the product quality of the fermented soybean meal is improved; moreover, the viscosity of the fermented soybean meal and the requirement on equipment can be greatly reduced, and the comprehensive cost is reduced.

Owner:CHINA AGRI UNIV

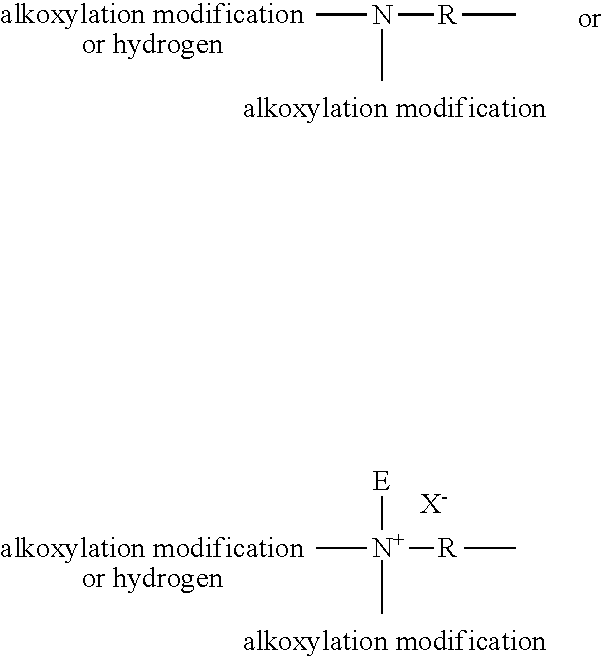

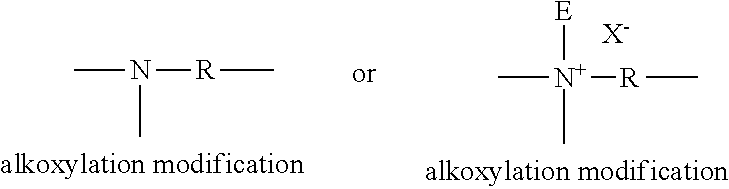

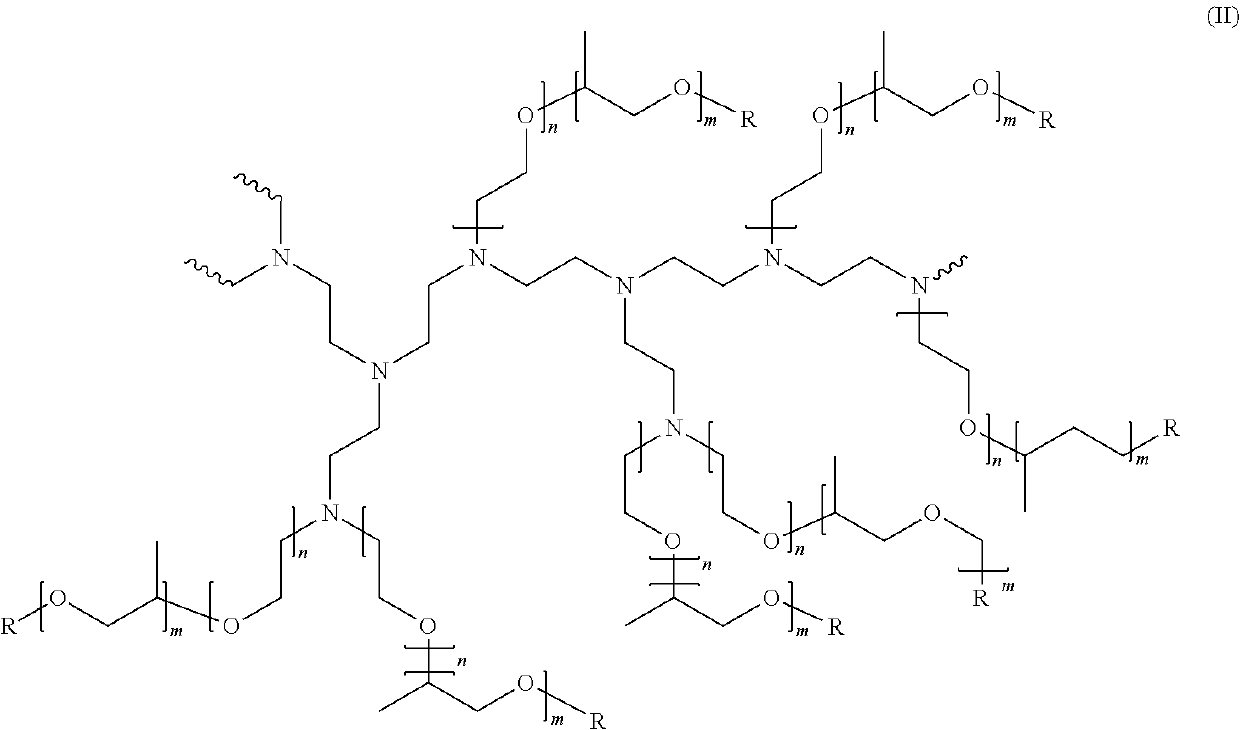

Detergent composition

InactiveUS20190144788A1Fine foamDesirable suds volume sudsOrganic detergent compounding agentsDetergent mixture composition preparationBeta-conglycininSurfactant system

The present invention is directed to a detergent composition having a chemically or physically modified soy protein selected from the group consisting of a chemically or physically modified soy 2S conglycinin, and a chemically or physically modified soy 7S beta-conglycinin, a surfactant system, and optionally an unmodified soy protein selected from the group consisting of an unmodified soy 2S conglycinin, an unmodified soy 7S beta-conglycinin, and mixtures thereof. Methods of making and using such compositions are also provided.

Owner:THE PROCTER & GAMBLE COMPANY

Method for detecting conglycinin sensitization peptide fragment and eliminating conglycinin sensitization

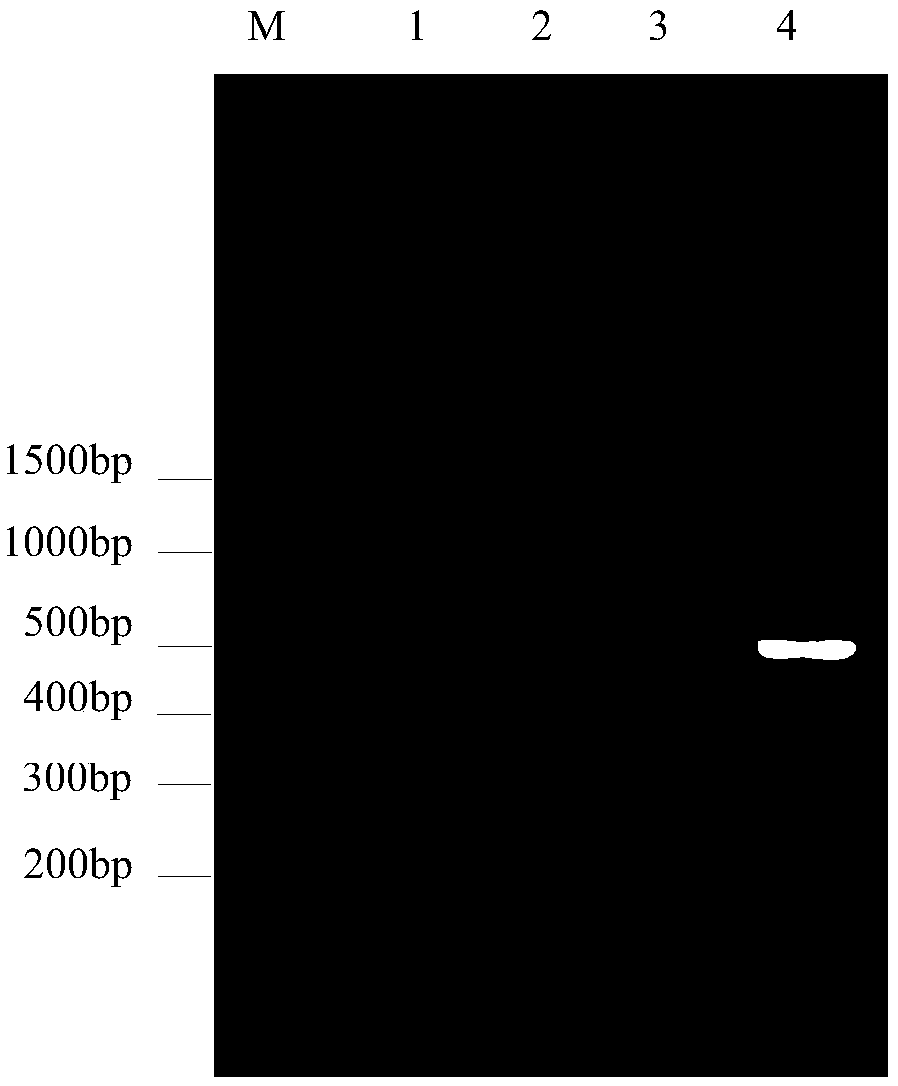

ActiveCN111955648AGood processing and functional propertiesFood ingredientsBiological testingAnaphylaxisAlkaline proteinase

The invention discloses a method for detecting a conglycinin sensitization peptide fragment and eliminating conglycinin sensitization. The method comprises conglycinin sensitization peptide fragment detection and conglycinin sensitization elimination. According to the invention, the anaphylaxis of the conglycinin is closely related to an anti-enzymolysis peptide fragment generated after digestionof the conglycinin; on the basis, the invention provides a method for modifying the conglycinin through alkaline protease low-limit hydrolysis, the conglycinin prepared by the method has good processing functional properties, meanwhile, the anti-enzymolysis peptide fragment is eliminated after in-vitro simulated digestion, and the sensitization is not detected through an immunoblotting experiment.The invention provides a method and a basis for development of hypoallergenic soybean protein.

Owner:JIANGNAN UNIV

Biological efficient mixed protein feed as well as preparation method and application thereof

InactiveCN109007323AIncrease contentImprove digestion utilizationAnimal feeding stuffAccessory food factorsMetaboliteFermentation

The invention relates to the technical field of preparation of biological feed and in particular relates to biological efficient mixed protein feed as well as a preparation method and application thereof. The method comprises the following steps: 1) preparing a compound protein substrate; 2) preparing a compound fermentation bacterium solution; 3) inoculating the bacterium solution obtained by step 2) into a compound protein raw material in step 1); 4) fermenting the compound protein raw material inoculated with the bacterium solution in step 3) to form fermented compound protein; 5) carryingout low-temperature drying on the fermented compound protein obtained by step 4) and crushing to form a biological efficient mixed protein feed finished product. According to the biological efficientmixed protein feed provided by the invention, a proper strain and a proper enzyme are compounded to carry out fermentation, and a low-temperature drying technology is adopted, so that the bioactivityof a metabolic product after fermentation is greatly improved, and the quantity of viable bacteria and the content of acid-soluble protein are about three times of that of common fermented protein type products; the content of glycinin and beta-conglycinin in the product is degraded by about 65 percent and is one time or more than one time of that of like products; the content of free gossypol islower than 500mg / kg and is degraded by 75 percent or more, and the capability of digesting and absorbing vegetable protein by animals can be remarkably improved.

Owner:圣百奥(山东)生物科技有限公司

Destructive beta-conglycinin beta subunit processing antigen area and screening method based on phage display technological orientation

The invention discloses a destructive beta-conglycinin beta subunit processing antigen area and a screening method based on phage display technological orientation. The amino acid sequence of the antigen area is as shown in SEQ ID NO. 15. By the aid of a series of bioinformatics software and reference of an analyzed beta-conglycinin three-dimensional crystalline structure of a PDB (protein database), the antigen area of ultrahigh-pressure destructive beta-conglycinin is researched by a phage display technology, a beta-conglycinin beta subunit and overlapping protein thereof are represented onthe surface of a phage, and an area with the beta-conglycinin beta subunit with antigenicity reduced by an ultrahigh-pressure is accurately positioned. A theoretical basis for screening processing methods is provided for food industry, and an application product for rapidly detecting the desensitization effect of processed food can be further developed.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

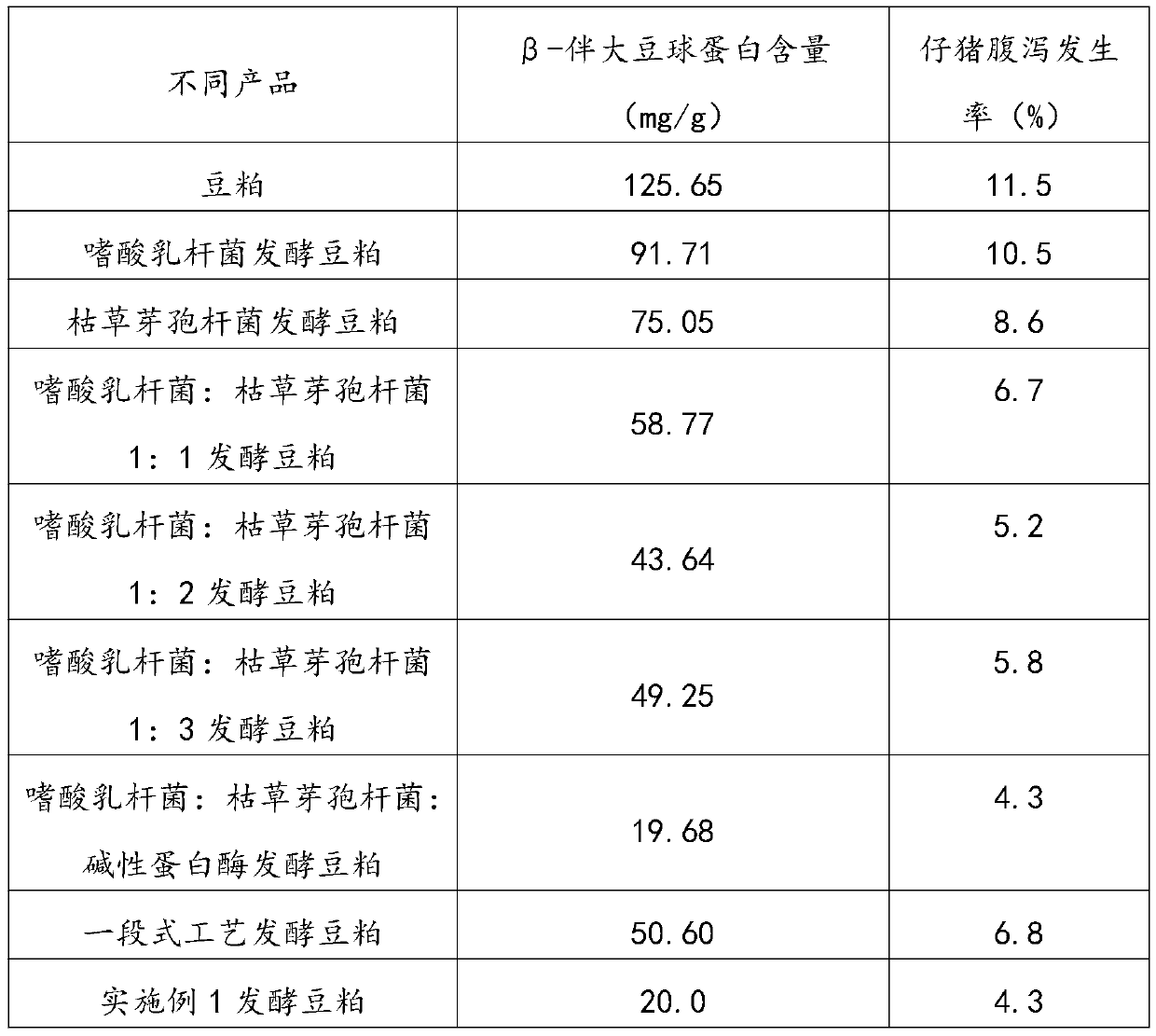

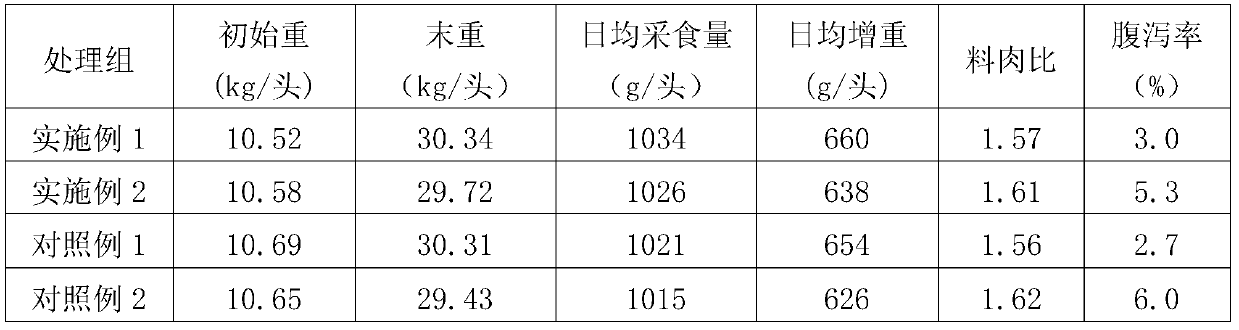

Fermentation method for reducing beta-conglycinin in soybean meal

InactiveCN110521863AReduce the incidence of diarrheaPromote formationFood processingAnimal feeding stuffAlkaline proteaseAntigen

The invention discloses a fermentation method for reducing beta-conglycinin in soybean meal. Lactobacillus acidophilus and bacillus subtilis are subjected to liquid fermentation culture by fermentation tanks separately, and then, fermentation culture solutions of the two strains are mixed to form a probiotic fermentation solution; and the probiotic fermentation solution, alkaline protease, water and soybean meal are mixed to obtain a fermentation mixture, the mixture is fermented at 30 DEG C for 48 h and heated to 50 DEG C to be fermented for 24 h, and drying is performed to obtain fermented soybean meal. The content of the beta-conglycinin in the fermented soybean meal prepared by the fermentation method provided by the invention is low, and meanwhile, the piglet diarrhea rate caused by antigen protein beta-conglycinin in the fermented soybean meal is reduced.

Owner:南京致润生物科技集团有限公司

Antigen region for processing destroyed beta-conglycinin alpha'subunit based on phage showing technology positioning and screening method thereof

The invention discloses an antigen region for processing destroyed beta-conglycinin alpha'subunit based on phage showing technology positioning and a screening method thereof. The amino acid sequenceof the antigen region is shown as SEQ ID NO.11. The antigen region for processing destroyed beta-conglycinin is researched by using a series of bioinformatics software, referring the beta-conglycininthree-dimensional crystalline structure analyzed by a PDB database and using a phage showing technology; the total length of the beta-conglycinin alpha'subunit and overlapping segmented protein are shown on the phage surface, so that regions with beta-conglycinin alpha'subunit antigenicity reduction caused by different processing methods are precisely positioned. Theoretical basis of processing method screening is provided for food industry; an application product for fast detecting the processed food desensitization effect can be further developed.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Compound feed for suckling pigs without animal proteins and preparation method thereof

InactiveCN110236011AReduce dependenceLow costFood processingAnimal feeding stuffAnimal scienceAnimal protein

The invention relates to the technical field of special feed for young animals, in particular to a compound feed for suckling pigs without animal proteins and a preparation method thereof. The compound feed is prepared from, by weight, 50.3-70.5 parts of corn, 12-18 parts of soybean meal, 8-12 parts of expanded whole fat soybeans, 3-8 parts of fermented soybean meal, 1.5-2.0 parts of calcium hydrogen phosphate, 0.5-1.2 parts of stone powder, 1.2-2.0 parts of soybean oil, 0.3-0.5 part of sodium chloride, and 3-6 parts of a premixed feed, wherein in the fermented soybean meal, the content of small peptides is 20 wt% or above, the content of beta-conglycinin is less than 12mg / g, the content of soybean globulin is less than 20mg / g, the content of stachyose is less than <0.5 wt%, and the content of raffinose is less than 0.5 wt%. By replacing the fish powder in the original formula with the fermented soybean meal, the dependence of the compound feed for the suckling pigs on animal raw materials is reduced under the condition of maintaining the animal growth performance of the original feed, and therefore, long-term stable formulation cost and product quality can be ensured.

Owner:东莞正大康地饲料有限公司

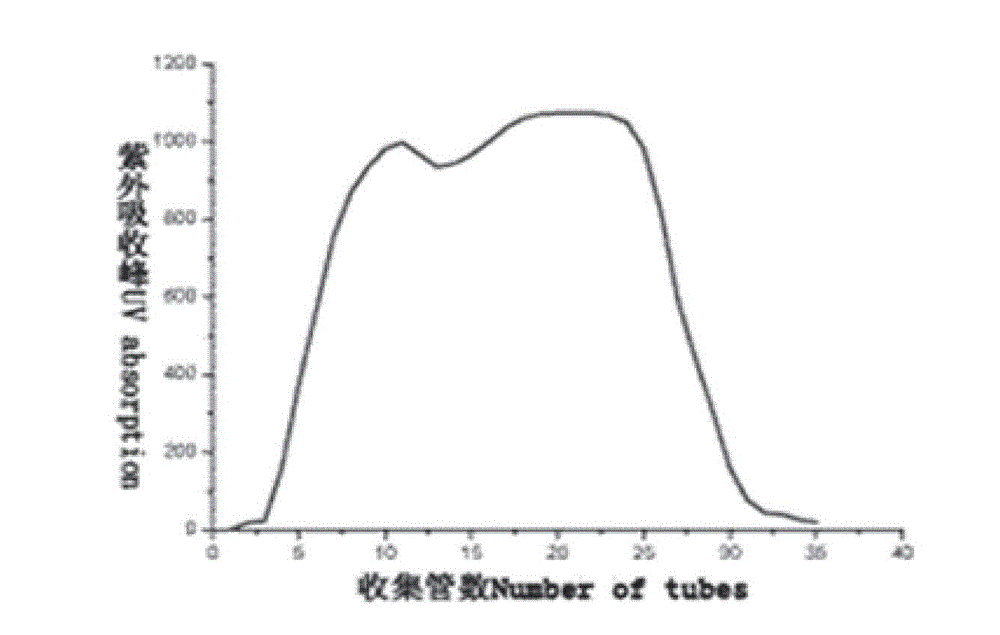

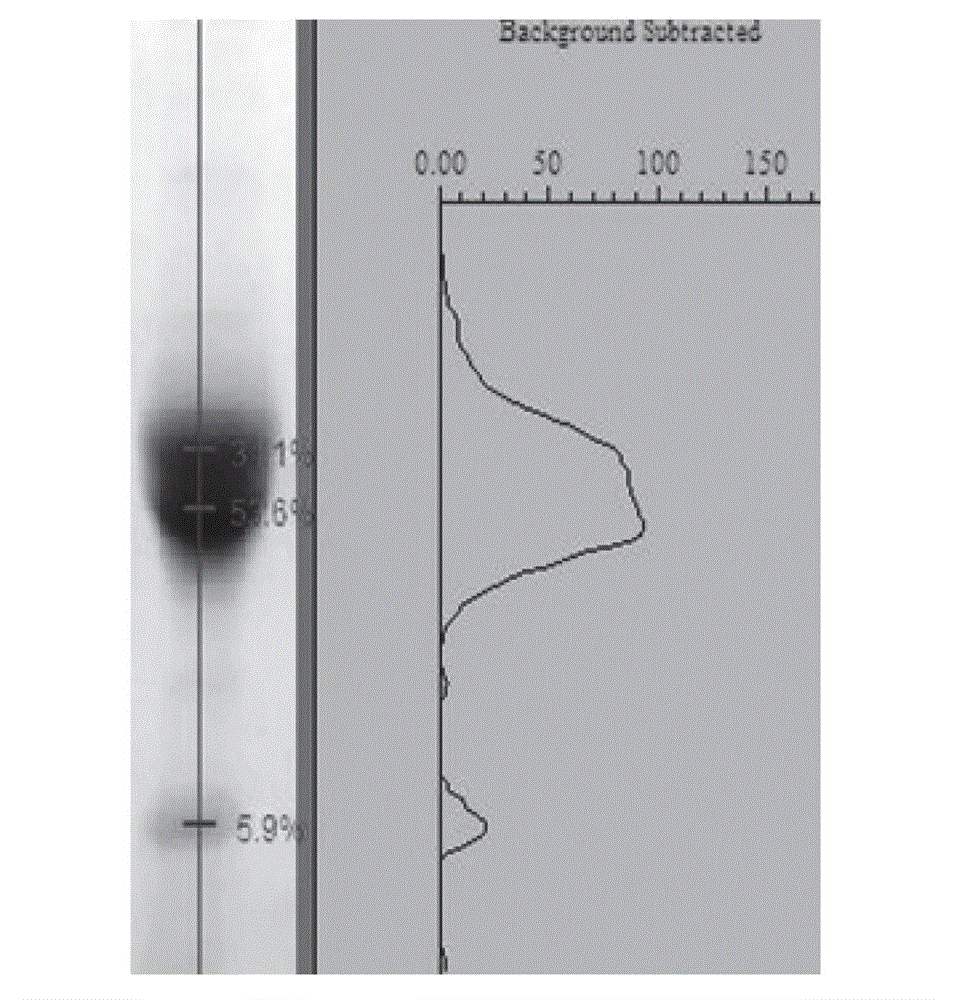

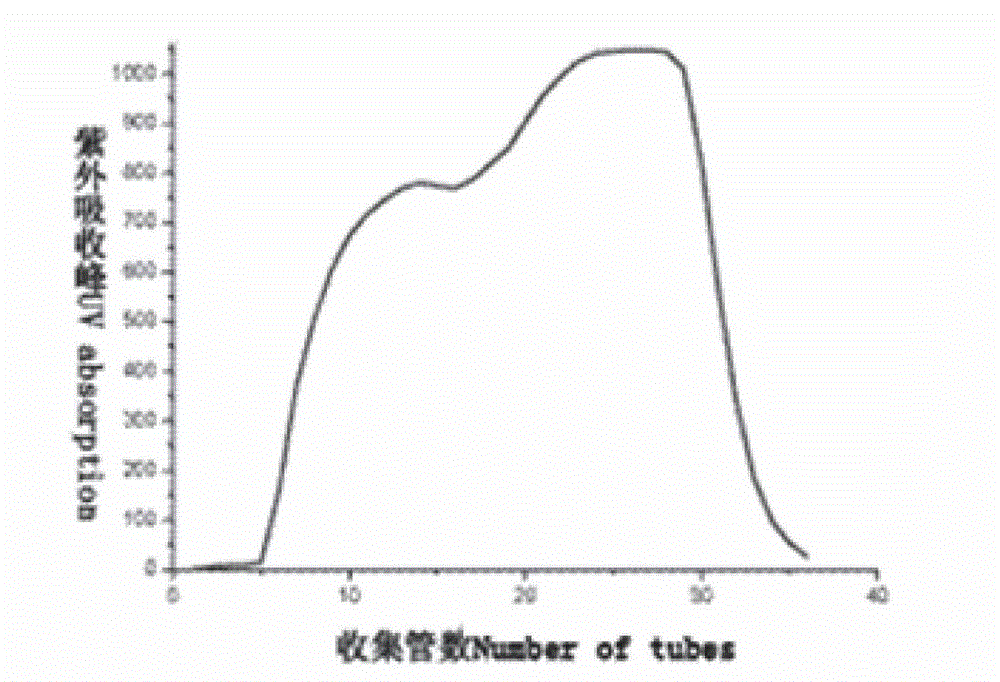

Separation processes for soy protein

InactiveUS20150299275A1Other chemical processesProtein composition from vegetable seedsChemical structureTrypsin inhibitor

The invention provides a process for the separation of soy protein. The process begins with an aqueous extract or solution of soy protein, which is passed through at least one expanded bed absorption (EBA) process. The EBA process comprises contacting the aqueous extract or solution of soy protein with at least one adsorbent resin, said adsorbent resin comprising at least one ligand (L1 or L2), having particular chemical structures. Proteins of interest (e.g. trypsin inhibitor (TI) protein or beta-conglycinin) are isolated by eluting them from said adsorbent resin. The invention also provides various novel protein compositions obtainable via the method of the invention.

Owner:UPFRONT CHROMATOGRAPHY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com