Fermentation method for reducing beta-conglycinin in soybean meal

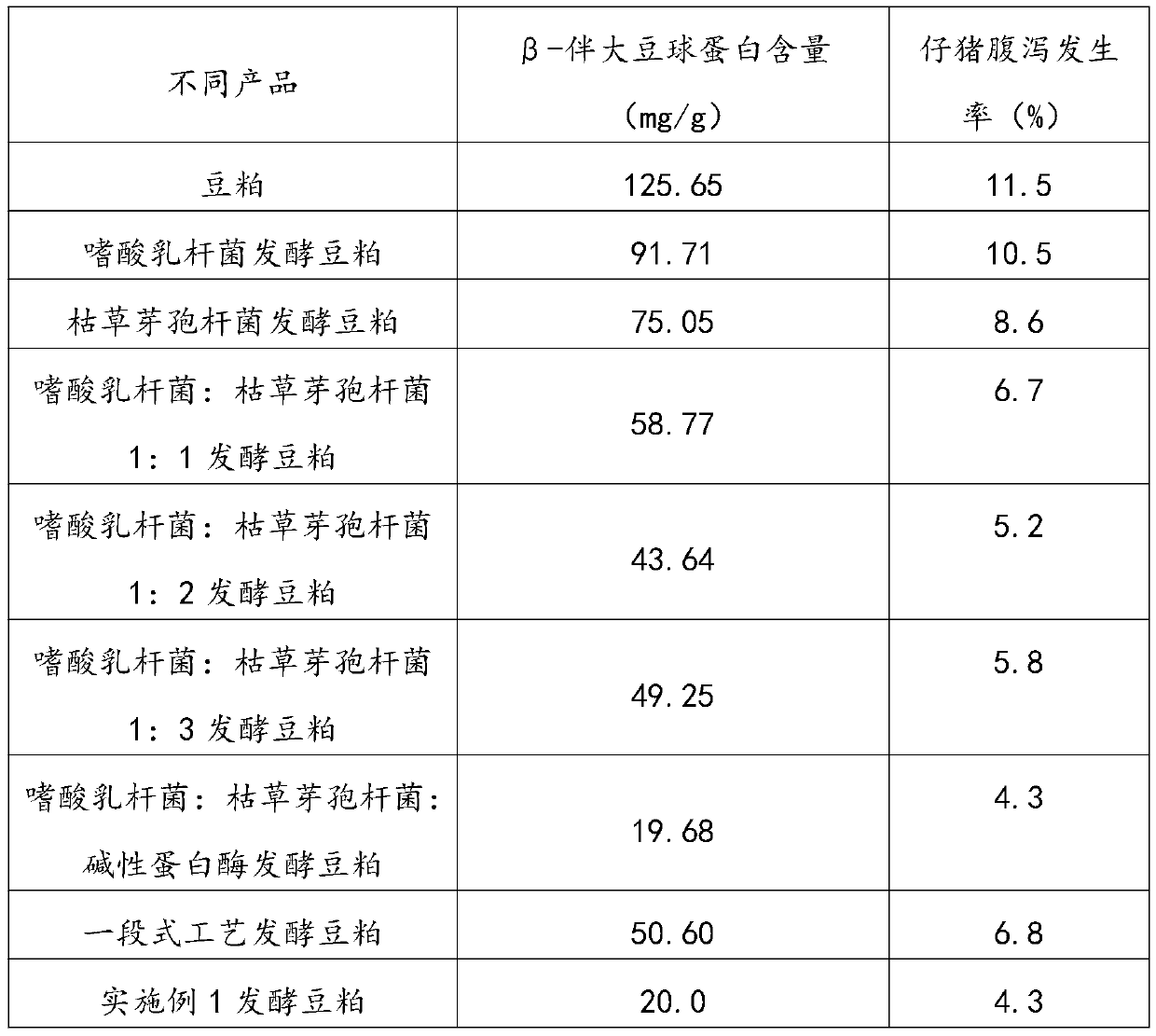

A technology of conglycinin and fermentation method, which is applied in the field of soybean meal with low β-conglycinin, can solve problems such as damage, and achieve the effects of prolonging fermentation time, increasing fermentation temperature and reducing the incidence of diarrhea.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Lactobacillus acidophilus and Bacillus subtilis are respectively cultured in a fermenter, and mixed in a ratio of 1:2 by volume;

[0023] The liquid fermentation medium for Bacillus subtilis is composed of: 3 g of beef extract, 10 g of glucose, 10 g of peptone, and 5 g of sodium chloride per liter; the liquid fermentation medium for Lactobacillus acidophilus is composed of: Glucose 20g, peptone 10g, yeast extract 5g preparation. Culture conditions and time: Bacillus subtilis was cultured at 37°C and 180 rpm for 24 hours, and Lactobacillus acidophilus was cultured at 37°C and 120 rpm for 24 hours. The OD600 values of Lactobacillus acidophilus and Bacillus subtilis after liquid fermentation were 2.0 and 2.15 respectively;

[0024] Then mix evenly according to the weight ratio of probiotic fermentation liquid: alkaline protease: water: soybean meal 1.5: 0.2: 40.3: 58, ferment at a fermentation temperature of 30°C for 48 hours, raise the temperature to 50°C for 24 hours,...

Embodiment 2

[0030] Lactobacillus acidophilus and Bacillus subtilis are respectively cultured in a fermenter, and mixed in a ratio of 1:2 by volume;

[0031] The liquid fermentation medium for Bacillus subtilis is composed of: 3 g of beef extract, 10 g of glucose, 10 g of peptone, and 5 g of sodium chloride per liter; the liquid fermentation medium for Lactobacillus acidophilus is composed of: Glucose 20g, peptone 10g, yeast extract 5g preparation. Culture conditions and time: Bacillus subtilis was cultured at 37°C and 180 rpm for 24 hours, and Lactobacillus acidophilus was cultured at 30°C and 120 rpm for 24 hours. The OD600 values of Lactobacillus acidophilus and Bacillus subtilis after liquid fermentation were 1.8 and 1.85 respectively;

[0032] Then mix evenly according to the weight ratio of probiotic fermentation broth: alkaline protease: water: soybean meal 1.0:0.2:44:54.8, ferment at 30°C for 48 hours, heat up to 50°C and continue to ferment for 2 hours, add glucose, After the ...

Embodiment 3

[0035] Prepare fermented soybean meal in the same way as in Example 2, the difference being that the OD600 values of Lactobacillus acidophilus and Bacillus subtilis after liquid fermentation culture are 2.0 and 1.85 respectively, probiotic fermentation broth: alkaline protease: water: The weight ratio of soybean meal is 1.2:0.2:42:56.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com