Method for eliminating beta-conglycinin in fermented soybean meal

A technology of conglycinin and fermented soybean meal, applied in the field of biochemistry, can solve the problems of increased material viscosity and increased drying cost, and achieve the effects of reducing content, viscosity, equipment requirements, and overall cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Steaming ball: a stainless steel spherical rotary steamer with a volume of 5 cubic meters, used as a container for steaming soybean meal.

[0030] Ambient temperature: 16-30°C.

[0031] Fermentation container: a cylindrical plastic barrel with a volume of 120 liters.

[0032] Lactic acid bacteria: Enterococcus faecium (Taiwan Yaxin Biotechnology Co., Ltd., the number of viable bacteria is not less than 100 billion cfu / g.)

[0033] Yeast: baker's yeast (Hubei Angel baker's yeast, food grade, the number of live bacteria is not less than 5 billion cfu / g.)

[0034] Soybean meal: China Ocean Cereals and Oils Industry (Shandong) Co., Ltd., passed through a 20-mesh sieve. The initial content of β-conglycinin in soybean meal is about 130ppm. The content analysis of β-conglycinin adopts kit detection method, and its quantitative detection limit is 2.0ppm.

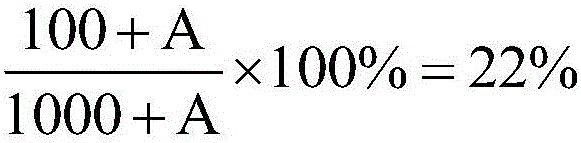

[0035] 1000kg of dehulled soybean meal is pre-adjusted with clear water to have a water content of 25% (weight ratio), ...

Embodiment 2

[0039] Steaming ball: a stainless steel spherical rotary steamer with a volume of 5 cubic meters, used as a container for steaming soybean meal.

[0040] Ambient temperature: 4~16℃.

[0041] Fermentation container: a cylindrical plastic barrel with a volume of 120 liters.

[0042] Lactic acid bacteria: Enterococcus faecium (Taiwan Yaxin Biotechnology Co., Ltd., the number of viable bacteria is not less than 100 billion cfu / g.)

[0043] Yeast: baker's yeast (Hubei Angel baker's yeast, food grade, the number of live bacteria is not less than 5 billion cfu / g.)

[0044] Soybean meal: China Ocean Cereals and Oils Industry (Shandong) Co., Ltd., passed through a 20-mesh sieve. The initial content of β-conglycinin in soybean meal is about 130ppm. The content analysis of β-conglycinin adopts kit detection method, and its quantitative detection limit is 2.0ppm.

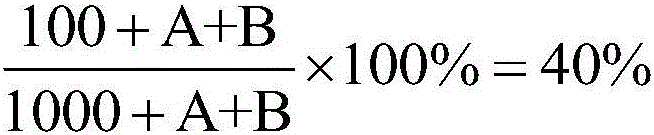

[0045] 1000kg of dehulled soybean meal is pre-adjusted with water to have a water content of 20% (weight ratio), transpor...

Embodiment 3

[0049] Steaming ball: a stainless steel spherical rotary steamer with a volume of 5 cubic meters, used as a container for steaming soybean meal.

[0050] Ambient temperature: 12-27°C.

[0051] Fermentation container: a cylindrical plastic barrel with a volume of 120 liters.

[0052] Lactic acid bacteria: Enterococcus faecium (Taiwan Yaxin Biotechnology Co., Ltd., the number of viable bacteria is not less than 100 billion cfu / g.)

[0053] Yeast: baker's yeast (Hubei Angel baker's yeast, food grade, the number of live bacteria is not less than 5 billion cfu / g.)

[0054] Soybean meal: China Ocean Cereals and Oils Industry (Shandong) Co., Ltd., passed through a 20-mesh sieve. The initial content of β-conglycinin in soybean meal is about 130ppm. The content analysis of β-conglycinin adopts kit detection method, and its quantitative detection limit is 2.0ppm.

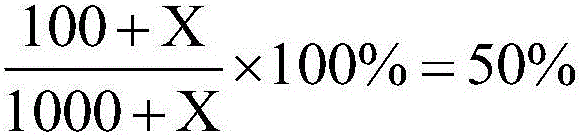

[0055] 1000kg of dehulled soybean meal is pre-adjusted with water to have a water content of 22.4% (weight ratio), tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com