Glycinin-rich and beta-conglycinin-rich protein fractions

A technology for conglycinin and glycinin, which is applied in the field of vegetable protein fractions rich in glycinin and β-conglycinin, can solve the problems of unsatisfactory yield, unsatisfactory purity, and unsatisfactory middle distillate fractions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

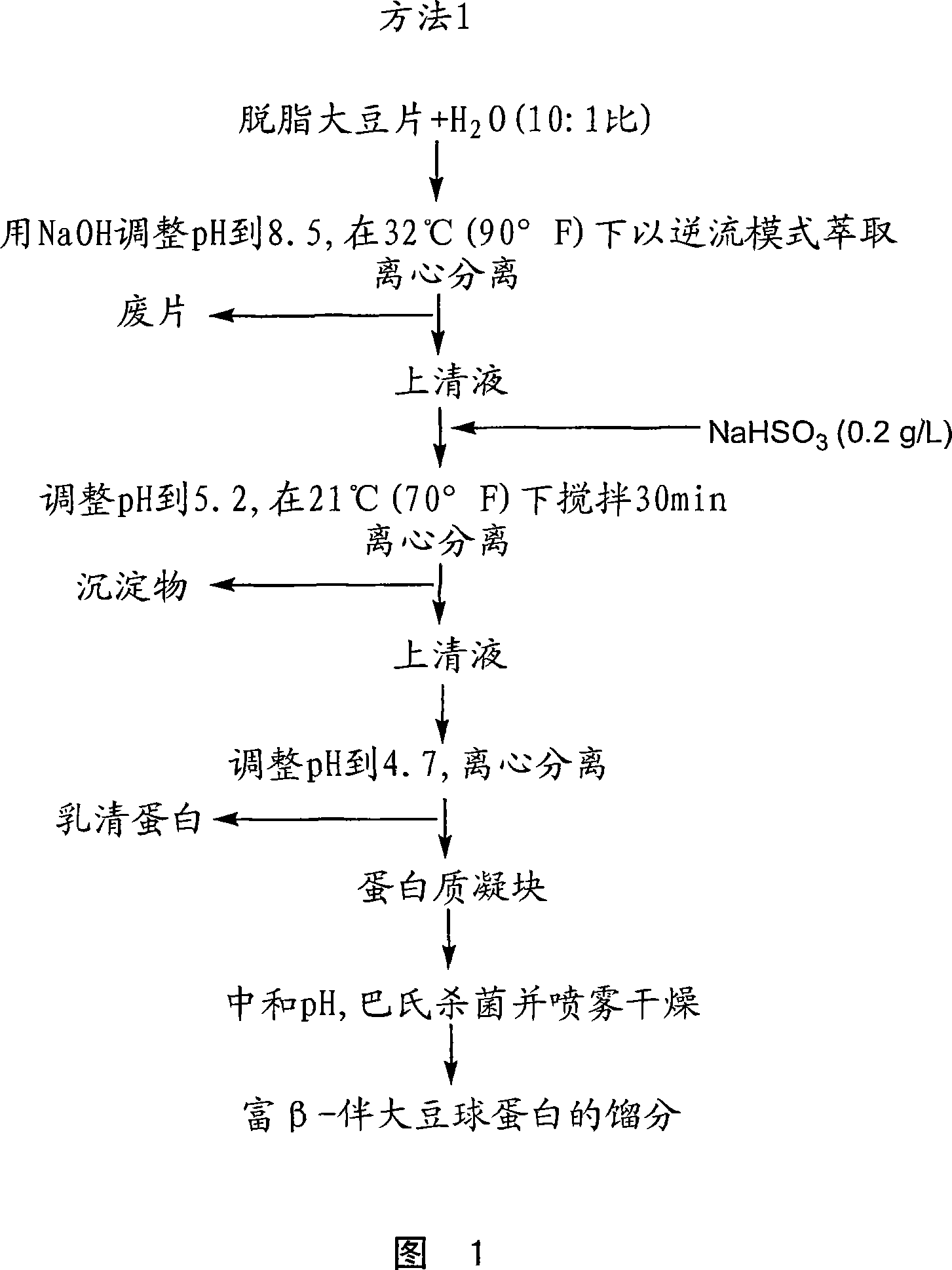

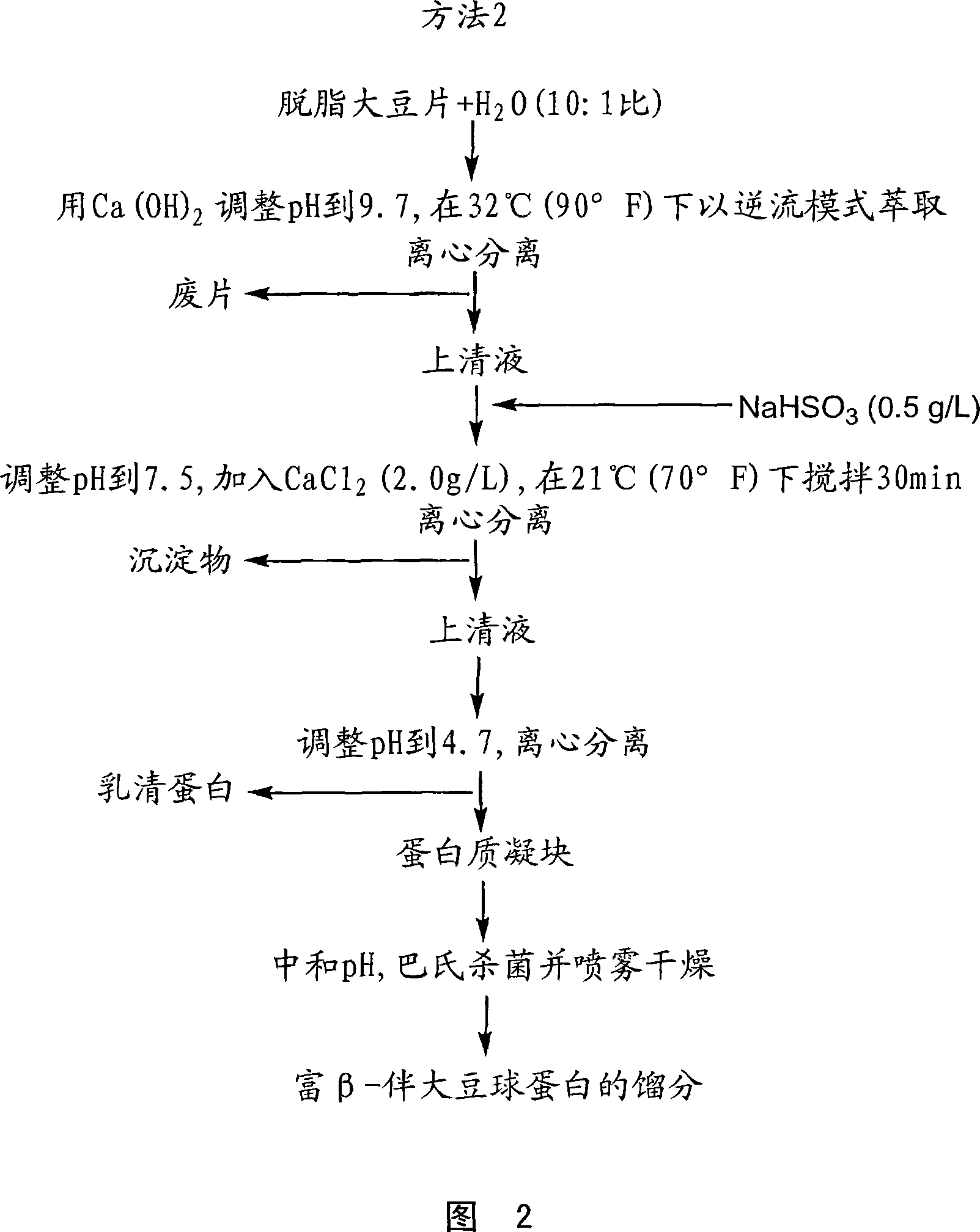

Method used

Image

Examples

Embodiment 1

[0173] This example illustrates the preparation of glycinin-rich and beta-conglycinin-rich fractions from soy protein extract solutions using varying amounts of calcium chloride. Different amounts of calcium chloride were added to the soy protein-containing extract solution in four separate precipitations.

[0174] For each of the four separate precipitations, degreased commercial white soy flakes produced by Cargill, Inc (Minneapolis, MN) and water (water to flakes) were prepared at a pH of 9.7 and a temperature of 32°C (90°F). The soy protein extract solution was prepared by contacting the mixture with calcium hydroxide in a weight ratio of 10:1) for 15 minutes. Soy flakes contain 50 wt% protein. Tablets contain 10-15% beta-conglycinin and 40-55% glycinin on a total protein basis.

[0175] To the extract solution was added sodium bisulfite (0.5 g, 0.2 g / l). In each run, hydrochloric acid (1.0 M) was added to the solution to adjust the pH to 7.5, and calcium chloride was a...

Embodiment 2

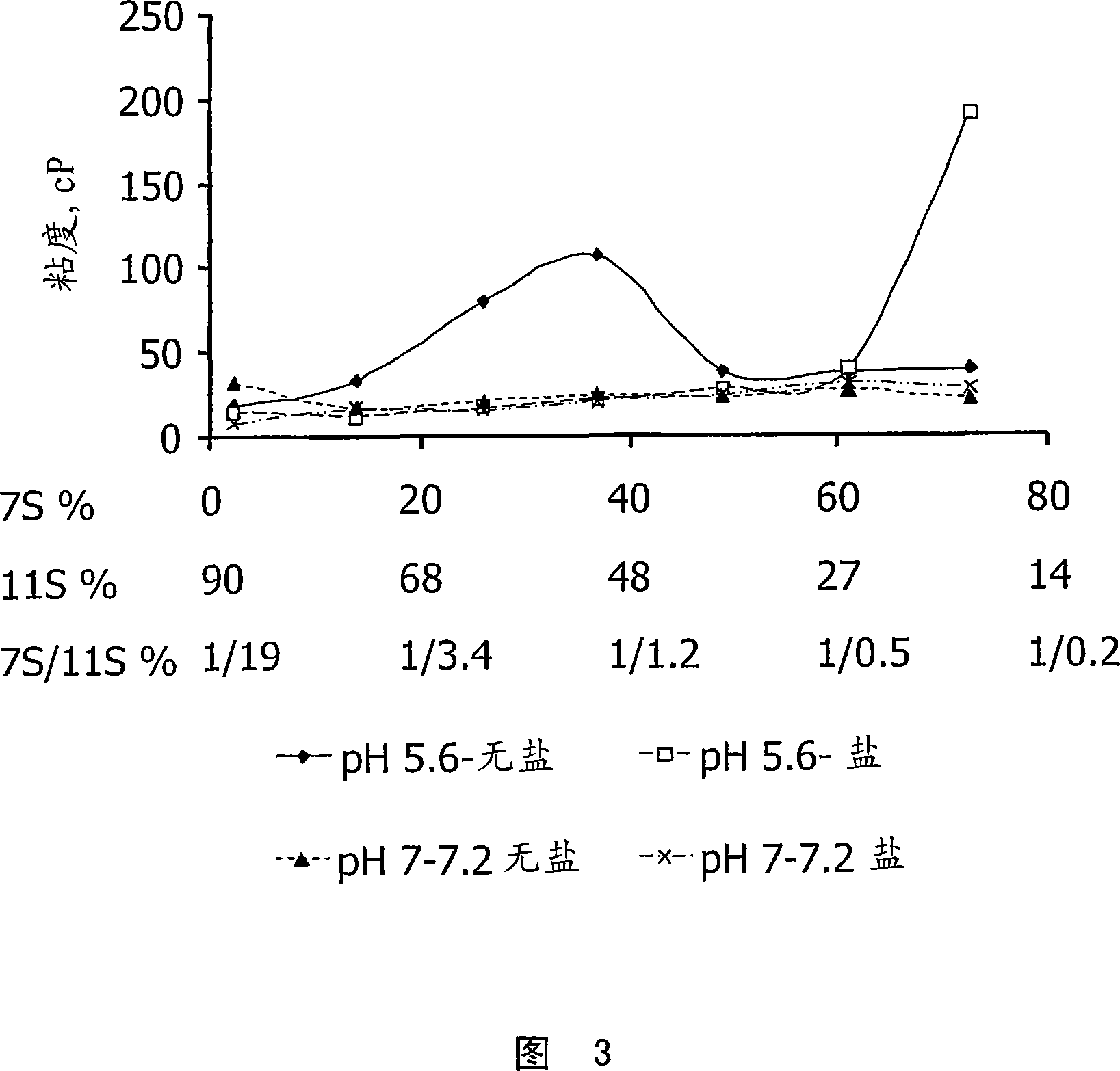

[0187] This example illustrates the effect of pH when glycinin-rich and beta-conglycinin-rich fractions are prepared from calcium chloride-introduced soy protein extract solutions as described in Example 1 above.

[0188] The pH of the extract solution prepared as described in Example 1 above was adjusted to enhance precipitation of the glycinin-rich fraction.

[0189] Sodium bisulfite (0.5 g / l extract solution) was added and the pH was adjusted to 7.5, 7.0, 6.5, 6.0 and 5.5 by adding hydrochloric acid (1.0 M) in 5 separate runs.

[0190] After the extract solution pH was adjusted to the desired level, calcium chloride (1.0 g / L extract solution) was added to each extract solution. The glycinin-rich pellet was separated from the supernatant by centrifugation as described in Example 1 above. The pH of the supernatant was then adjusted to 4.8 by adding hydrochloric acid (1.0 M) to precipitate the β-conglycinin-rich fraction. The [beta]-conglycinin fraction was also isolated and...

Embodiment 3

[0196] This example illustrates the effect of adding sodium bisulfite as a reducing agent when preparing glycinin-rich and beta-conglycinin-rich fractions from soy protein extract solutions prepared as described in Example 1 above.

[0197] Five precipitation experiments were performed, only varying the amount of sodium bisulfite added to the extract solution before precipitation of the glycinin-rich fraction. The amount of sodium bisulfite added to the extract per experiment was 0.1 g / extract, 0.2 g / extract, 0.3 g / extract, 0.4 g / extract and 0.5 g / extract. In each experiment, the respective amount of sodium bisulfite was added to the extract at pH 9.7.

[0198] Calcium chloride (1 g / l extract) was added to the extraction solution to precipitate the glycinin-rich fraction. The pH of the extract solution was then adjusted to 6.2 by adding hydrochloric acid (1.0 M) for glycinin precipitation, and the glycinin-rich precipitate was separated from the supernatant by centrifugation as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel strength | aaaaa | aaaaa |

| gel strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com