Binding device

A binding needle and needle loading technology, which is applied in the direction of nailing staple tools, nailing tools, manufacturing tools, etc., can solve the problems of large force, small contact area, user's hand fatigue and pain, etc. Easy to carry and relieve fatigue and pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

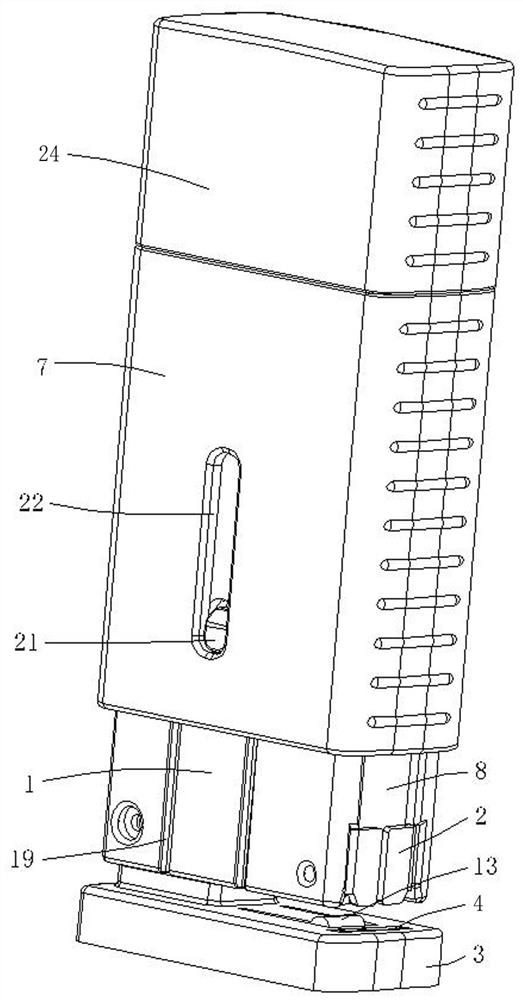

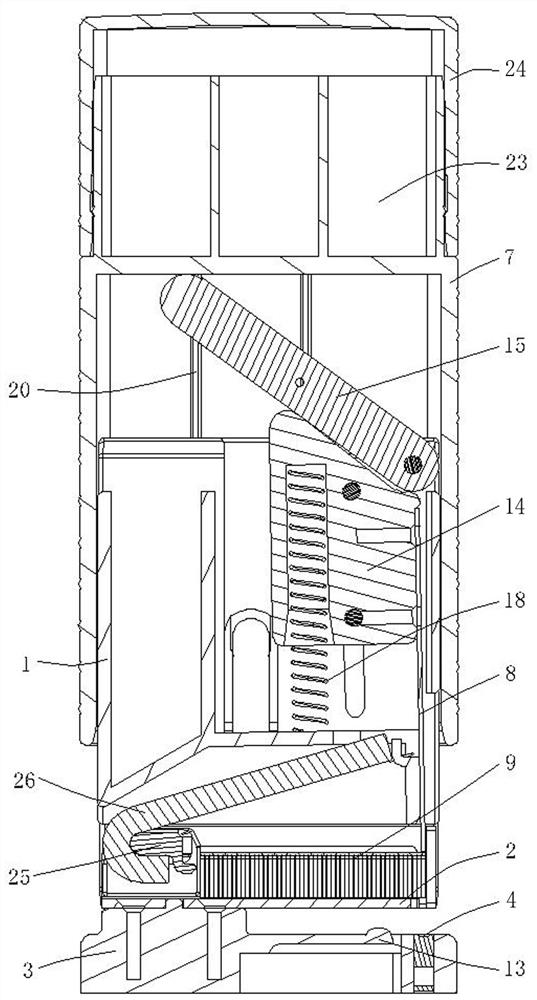

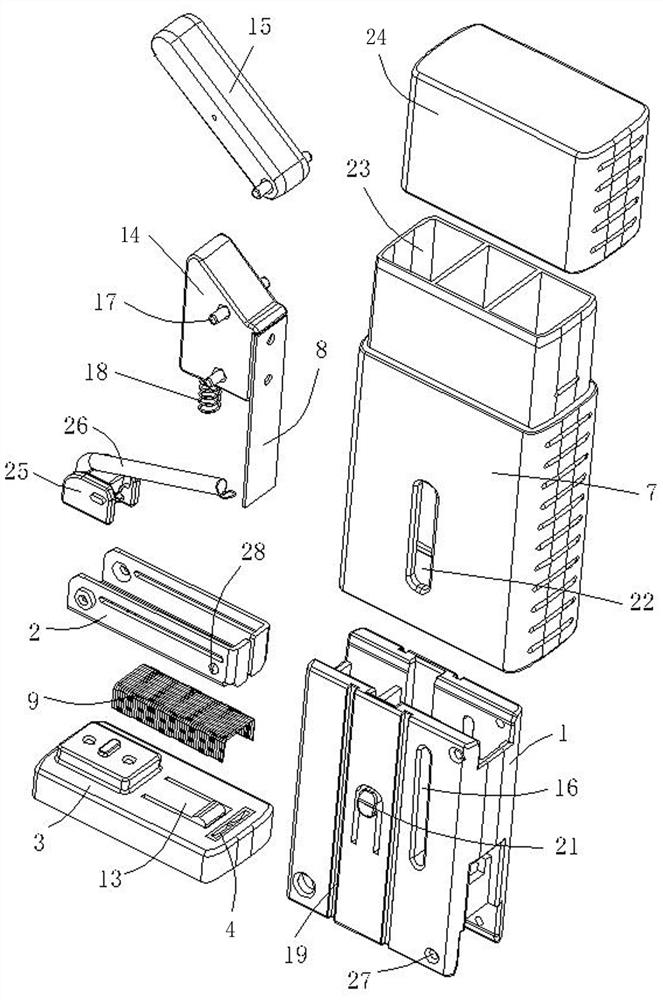

[0032] refer to Figure 1~Figure 10 , a binding device, including a main body 1, and a needle box 2 installed on the main body, a base 3 is provided below the needle box, and a bending groove 4 is provided on the base, and the bending groove 4 is used for The staples are bent;

[0033] The needle box 2 has a needle slot 5 for placing staples, and the end of the needle slot is provided with a drop hole 6 that is opposite to the bending slot and can pass through a single staple. 2 is provided with a needle pusher that can move the binding needle along the needle groove to the direction of the lower needle hole 6;

[0034] The main body 1 is slidably provided with a driver 7, and the main body is also movably provided with a needle pressing top plate 8 opposite to the needle drop hole. When the driver 7 is pressed, the driver will 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com