Evaluation method of grain structure uniformity, selection method of forging forming process

A technology of uniform organization and evaluation methods, which is applied in the direction of instruments, analytical materials, measuring devices, etc., to achieve accurate evaluation results

Active Publication Date: 2022-05-24

YANSHAN UNIV

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Furthermore, the purpose of the present invention is to solve the problem of evaluating the uniformity of the grain structure of aluminum alloy forgings, thereby establishing an evaluation function for the uniformity of grain structure of aluminum alloy forgings, thereby guiding the selection of the forming process and obtaining the best process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0035] The present invention will be described in further detail below with reference to the accompanying drawings and with examples of 7050 aluminum alloy forgings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

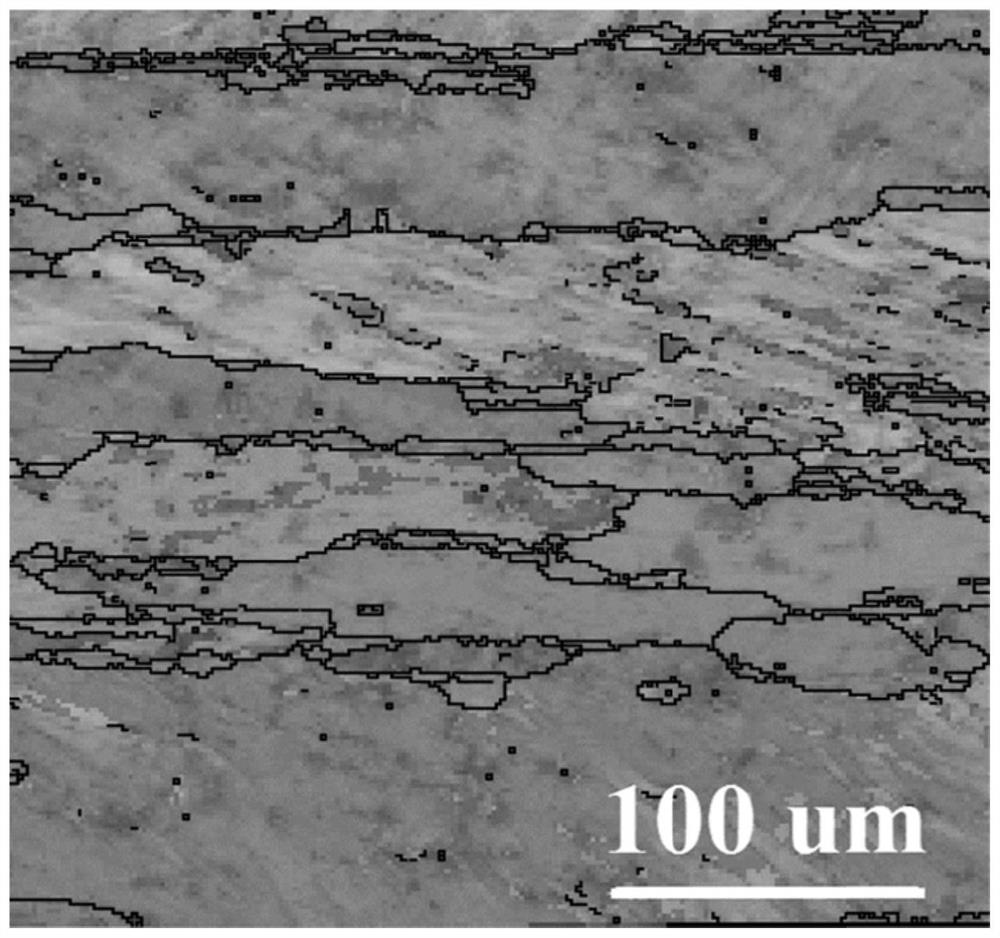

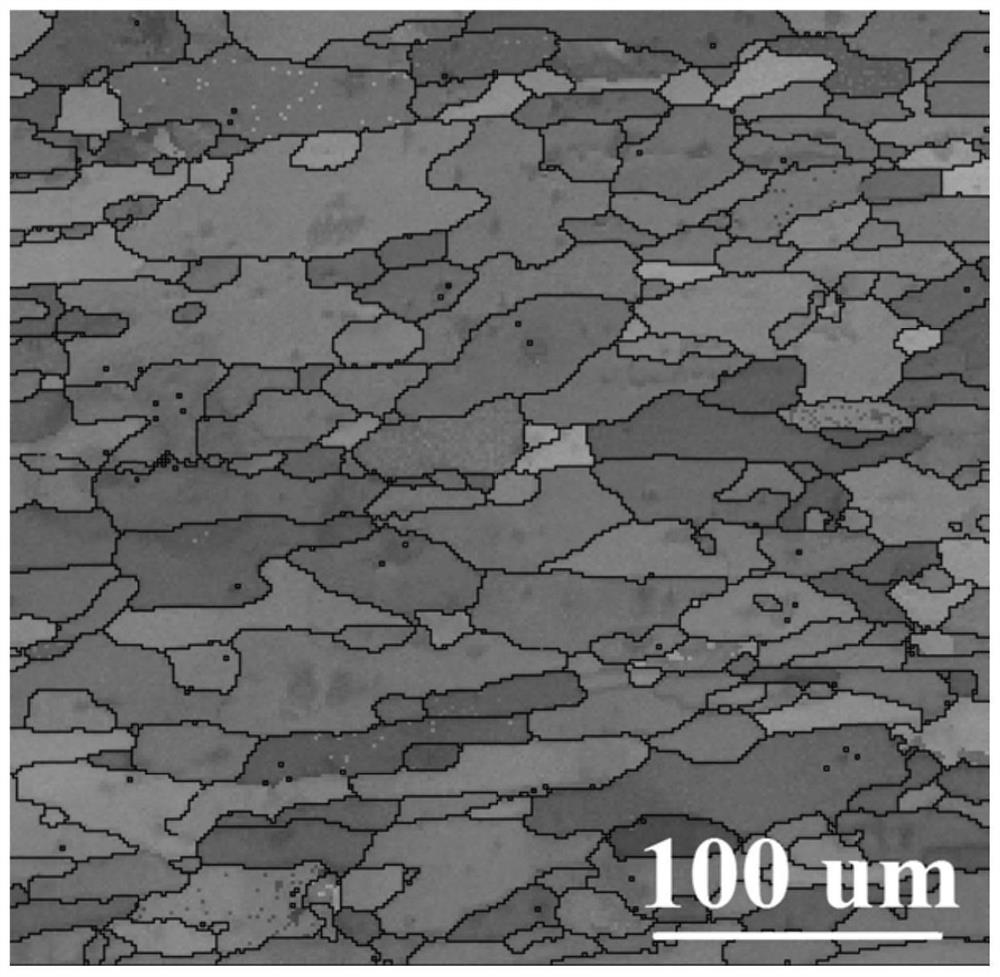

The invention provides a method for evaluating the uniformity of the grain structure of an aluminum alloy forging, which comprises a grain preservation step, a grain static recrystallization step, a metallographic structure surface photographing step, a grain size grade statistics step, and a forging grain structure Uniformity evaluation steps. Through the method of the invention, it becomes possible to evaluate the grain structure uniformity of aluminum alloy forgings easily and accurately.

Description

technical field [0001] The invention relates to the field of evaluation of grain structure uniformity of aluminum alloy forgings, and is a method for evaluating the overall grain structure uniformity of aluminum alloy forgings. Background technique [0002] Although the domestic large passenger aircraft C919 successfully made its maiden flight in 2017, aero-engines, aircraft control systems, landing gear systems, and large lightweight and high-strength aerostructures are several key factors that restrict domestic large passenger aircraft from going abroad. Among them, 7XXX aluminum alloy has the advantages of high strength and toughness, good plastic workability and heat treatment strengthening, and has become one of the main materials for large-scale lightweight and high-strength aerospace structural parts. [0003] 7050 aluminum alloy is very common to be formed by forging in order to meet the shape requirements of aviation construction. There are various modern forging f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G06V20/69C22F1/04G01N21/84

CPCG01N21/84C22F1/04G06V20/698

Inventor 胡建良王欢吴秀江金淼

Owner YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com