Forging die

A technology of molds and mold bases, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., which can solve the problems of inconvenient quick pick-up, inability to eject forgings, inability to separate forgings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

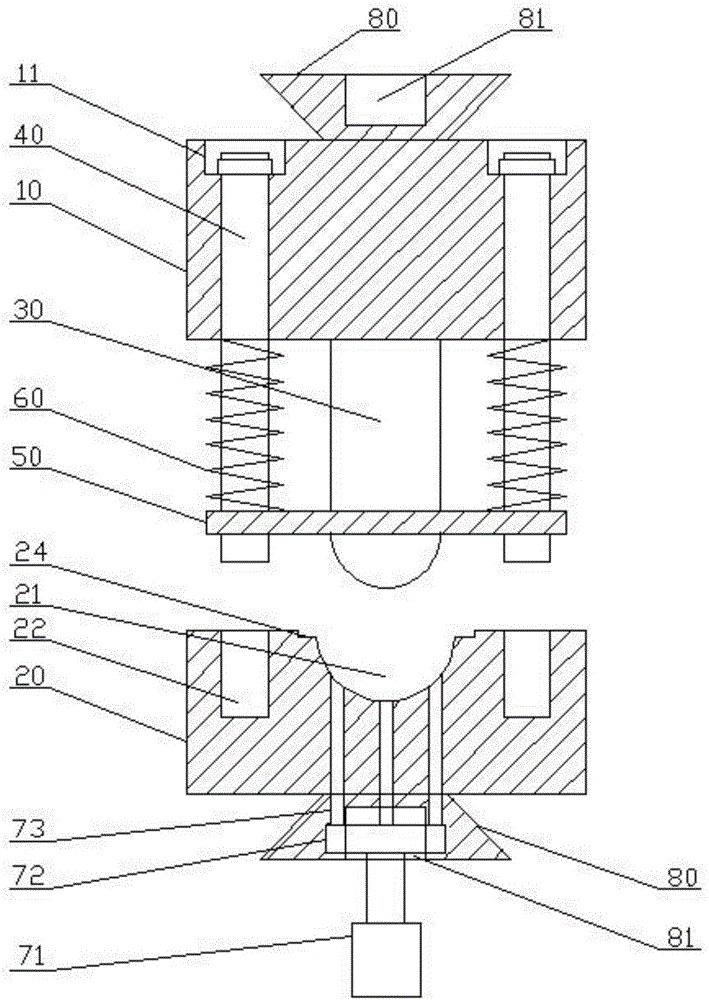

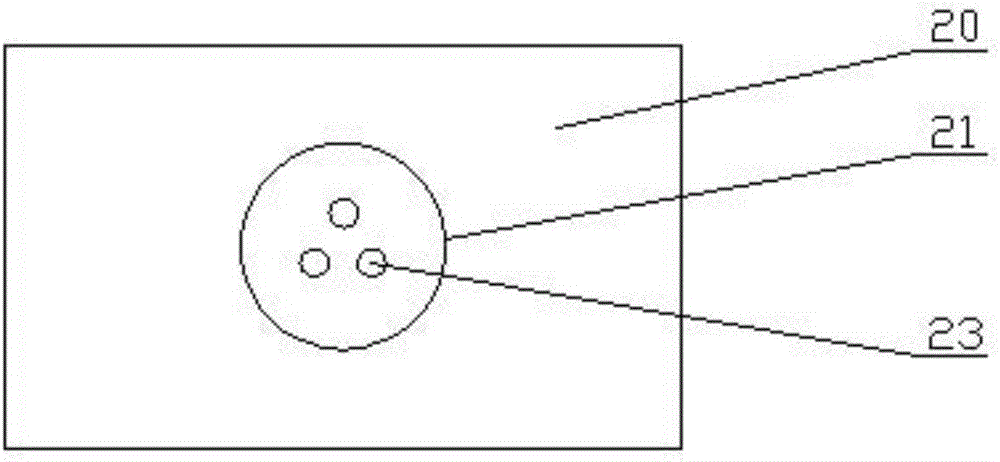

[0017] see figure 1 and figure 2 , a kind of forging mold described in a preferred embodiment of the present invention comprises an upper mold base 10 and a lower mold base 20, and the upper mold base 10 and the lower mold base 20 are provided with a tenon 80 that is quickly connected to the forging press, and the tenon 80 is provided with fixing hole 81, and upper mold base 10 is vertically connected with the punch 30 toward lower mold base 20, and lower mold base 20 is provided with the punching groove 21 that matches with punch 30; Both sides of the punch 30 are provided with guide posts 40, and the lower die base 20 is provided with guide grooves 22 corresponding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com