Single-person operation tool for J-shaped wire clamp

A single-person operation and wire clip technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of difficulty, time-consuming, high physical strength requirements, and achieve the effect of neat and beautiful installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

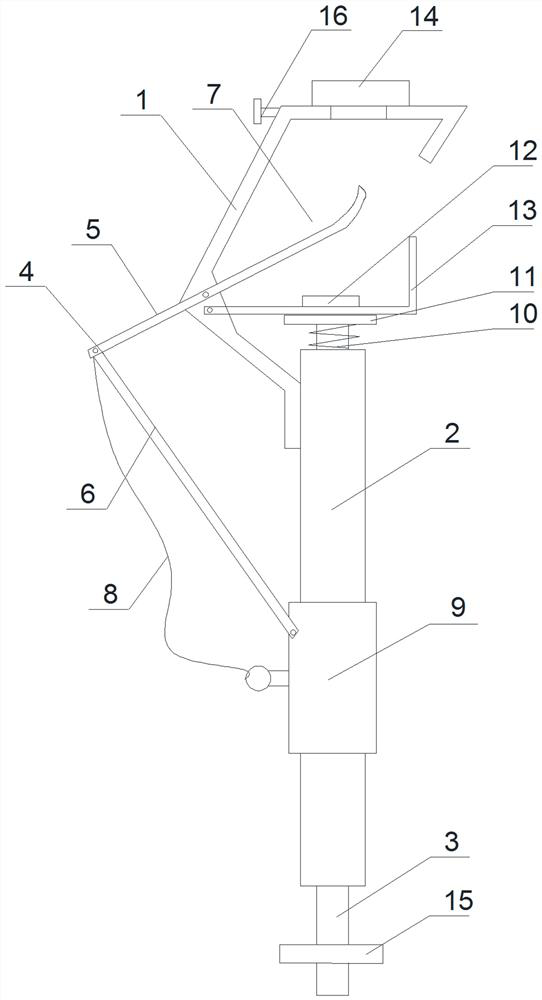

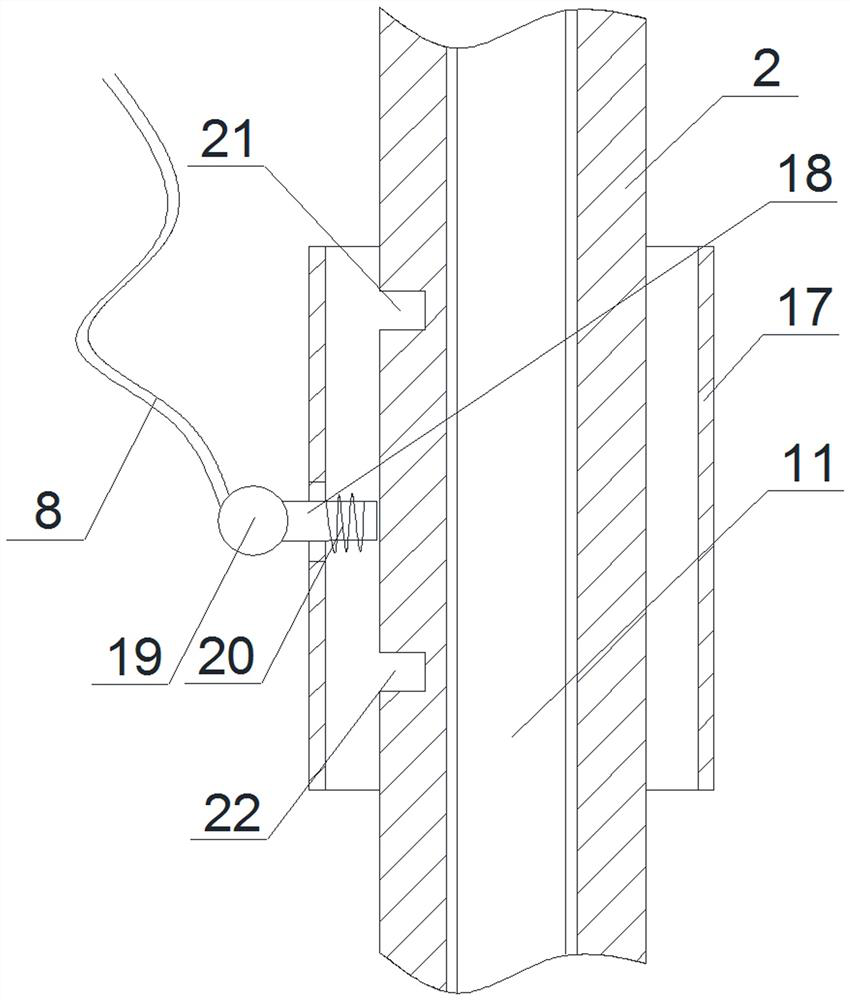

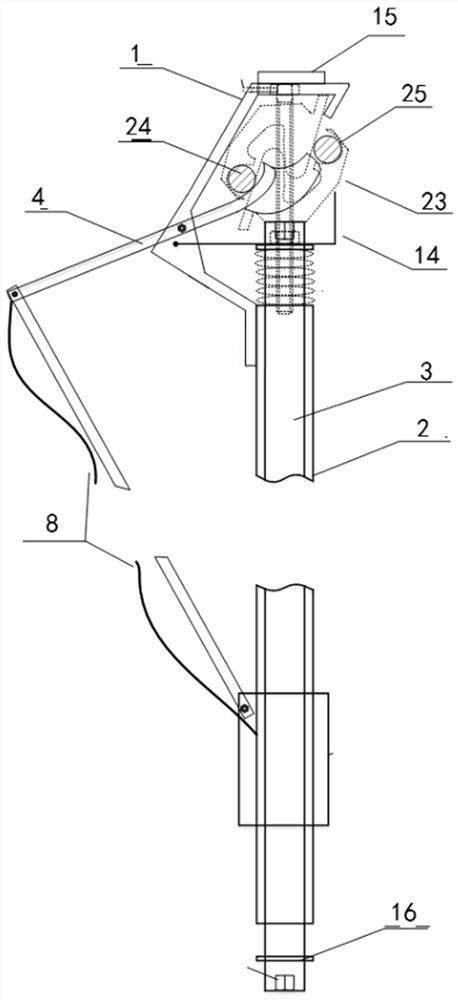

[0021] Such as figure 1 As shown, a single-person operation tool for a J-shaped wire clamp includes a wire clamp fixing frame 1 for fixing a J-type wire clamp, an insulating outer rod 2 fixedly connected to the bottom of the wire clamp fixing frame 1, and an insulating outer rod 2 sleeved on an insulating The insulating inner rod 3 inside the outer rod 2 and moving relative to the insulating outer rod 2, the bolt fastening device fixedly connected to the top of the insulating inner rod 3 by welding, and the lead wire that is movably connected with the wire clamp holder 1 and used to fix the lead wire Fixing mechanism 4, a locking mechanism 9 that is sleeved on the insulating outer rod 2 and used to lock the lead wire fixing mechanism 4, and a limit frame 13 that is movably connected with the clamp fixing mechanism 4 and located above the bolt fastening mechanism, is locked Mechanism 9 can be connected with lead wire fixing mechanism 4 by unlocking rope, can make operating pers...

Embodiment 2

[0027] Such as figure 1 As shown, a single-person operation tool for a J-shaped wire clamp includes a wire clamp fixing frame 1 for fixing a J-type wire clamp, an insulating outer rod 2 fixedly connected to the bottom of the wire clamp fixing frame 1, and an insulating outer rod 2 sleeved on an insulating The insulating inner rod 3 inside the outer rod 2 and moving relative to the insulating outer rod 2, the bolt fastening device fixedly connected to the top of the insulating inner rod 3 by welding, and the lead wire that is movably connected with the wire clamp holder 1 and used to fix the lead wire Fixing mechanism 4, a locking mechanism 9 that is sleeved on the insulating outer rod 2 and used to lock the lead wire fixing mechanism 4, and a limit frame 13 that is movably connected with the clamp fixing mechanism 4 and located above the bolt fastening mechanism, is locked Mechanism 9 can be connected with lead wire fixing mechanism 4 by unlocking rope, can make operating pers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com