A pre-clamping device for clip-type anchors for frp

A pre-clamping and clip-type technology, which is applied in the erection/assembly of bridges, the processing of building materials, bridges, etc., can solve the problems that it is difficult to ensure that the pre-clamping force is accurate and the pre-clamping degree is in place, so as to improve the application advantages , strong versatility, and the effect of reducing local stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

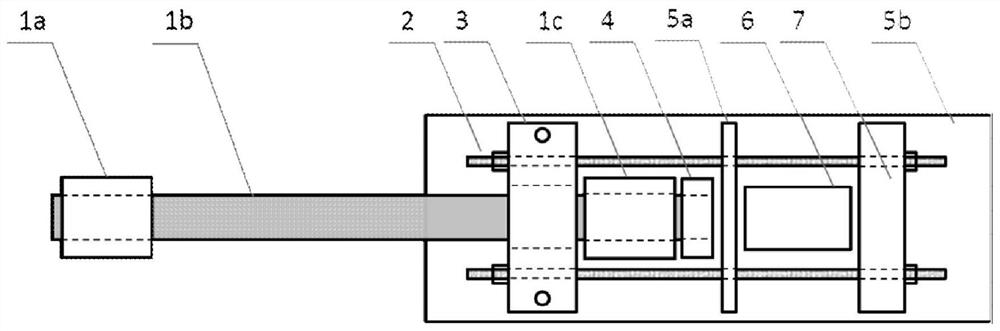

[0047] like figure 1 and figure 2 As shown in the figure, a clip-type anchorage pre-clamping device applied to FRP plates, the entire pre-clamping device, except the FRP plate to be clamped, is mainly composed of a force-transmitting screw and a matching nut 2, a sliding force-transmitting block 3, and a gasket. It is composed of key components such as block 4, structural foundation or base 5a, jack 6 with digital stopwatch, and reaction force block 7.

[0048] The two force-transmitting screws 2 pass through the connecting through holes on the sliding force-transmitting block 3, the structural foundation or base 5a and the reaction force block 7 in parallel in turn, and the two ends are fastened with nuts. The anchor head 1c to be clamped is built into the sliding block. Between the force transmission block 3, the structural foundation or base 5a, a jack 6 with a digital computer is built in between the structural foundation or base 5a and the reaction force block 7, formin...

Embodiment 2

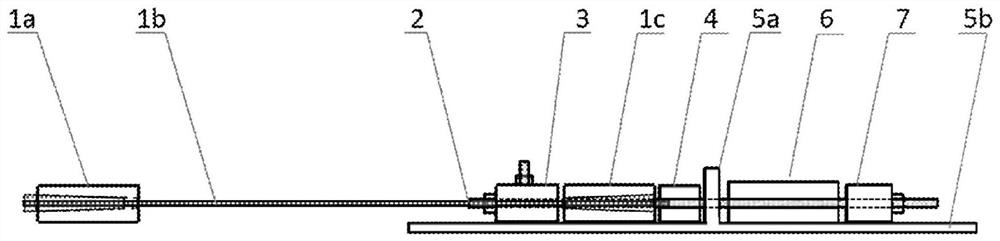

[0053] like image 3 and Figure 4 As shown in the figure, a clip-type anchorage pre-clamping device applied to FRP reinforcement, the entire pre-clamping device is mainly composed of a force-transmitting screw, a matching nut 2, and a sliding force-transmitting block 3 except the FRP reinforcement to be clamped. , cushion block 4, jack 6 with digital stopwatch and reaction force block 7 and other key components, eliminating the need for structural foundation or base part, mainly used in temporary or construction sites where pre-clamping accuracy is not high.

[0054] The two force-transmitting screws 2 pass through the connecting through holes on the sliding force-transmitting block 3 and the reaction force block 7 in parallel in sequence, and the two ends are fastened with nuts. The anchor head 1c to be clamped is built into the sliding force-transmitting block 3 and the cushion block 4, a jack 6 with a digital stopwatch is built in between the cushion block 4 and the react...

Embodiment 3

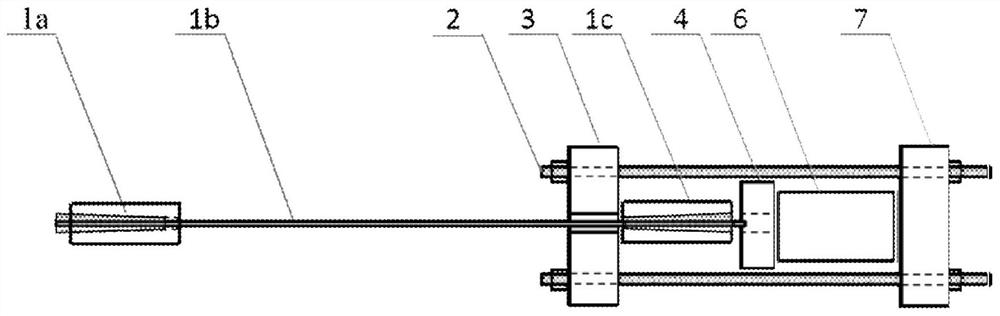

[0059] like Figure 5 and Image 6 As shown in the figure, a clip-type hinged anchorage pre-clamping device applied to FRP plates, the entire pre-clamping device except the FRP plate to be clamped, mainly consists of a force-transmitting screw, a matching nut 2, a sliding force-transmitting block 3. It is composed of key components such as the cushion block 4, the temporary cement base 5a, the jack 6 with the digital computer and the reaction block 7; the temporary cement base 5a is temporarily fastened on the flat cement base 8 by two long bolts ; The inner edge of the sliding force transmission block 3 is a concave arc surface, which forms a hinge structure with the outer convex arc surface of the inner edge of the hinge anchor head during the pre-clamping process.

[0060] The two force-transmitting screws 2 pass through the connecting through holes on the sliding force-transmitting block 3, the temporary cement base 5a and the reaction force block 7 in parallel in turn, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com