A plant-wide monitoring system and monitoring method for loop performance evaluation

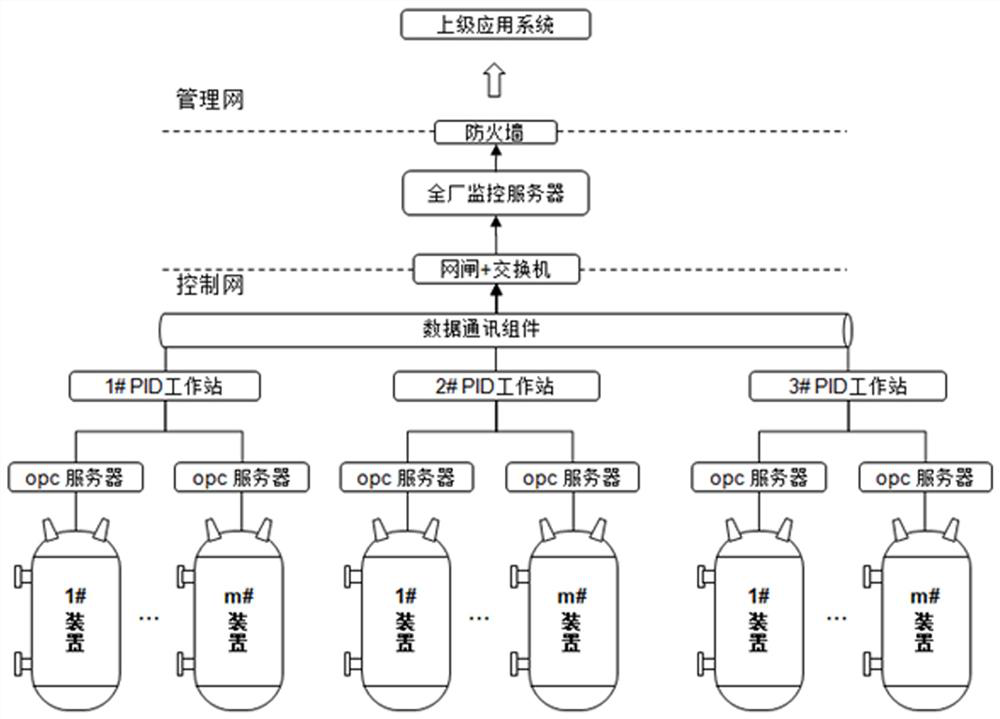

A monitoring system and loop performance technology, applied in general control system, test/monitoring control system, comprehensive factory control, etc., can solve the inconvenience of real-time monitoring and management of managers, does not support centralized monitoring of multiple sets of devices, evaluation object stay, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

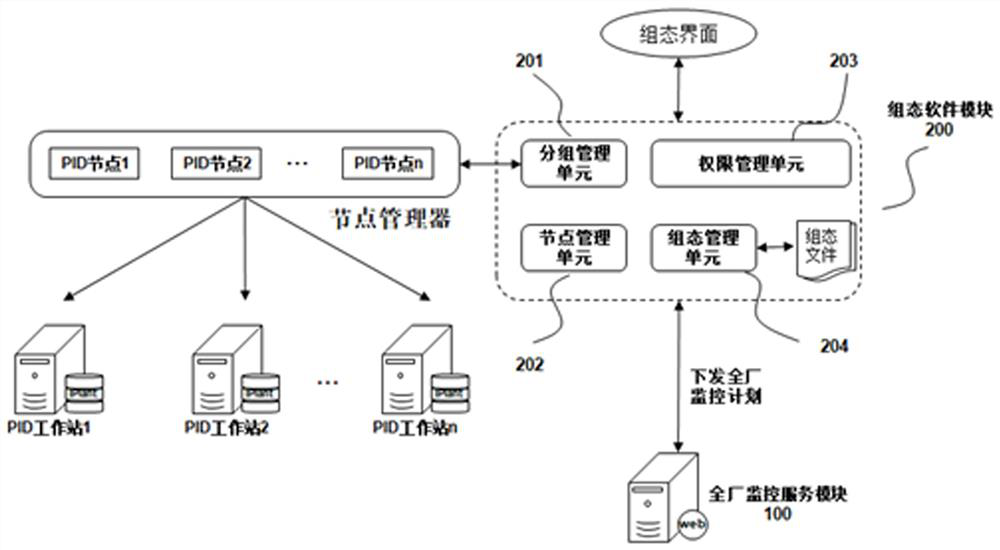

[0036] figure 2 It is a schematic diagram of the business flow of the configuration software module in the embodiment of the present invention. The specific implementation is as follows:

[0037] 1) Group management and node configuration: According to the operation guide of the configuration software module, start the group management work, through the PID performance evaluation node manager, according to the hierarchical relationship of each branch factory or operation department of the whole plant, create a corresponding PID performance evaluation workstation The virtual PID node of figure 2 The shown PID node 1, PID node 2...PID node n; then, configure the IP address and port number of the PID performance evaluation service of the branch factory for each virtual PID node, and link the newly created virtual PID node with the specific branch factory operation Bind the access connection address of the PID performance evaluation workstation in the department and generate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com