Vehicle body assembly and engineering vehicle

A car body and component technology, which is applied to vehicle parts, gas intake with power unit, power unit, etc., can solve the problems of enlarging the outline of the car body and encroaching on the outer space of the outline of the car body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

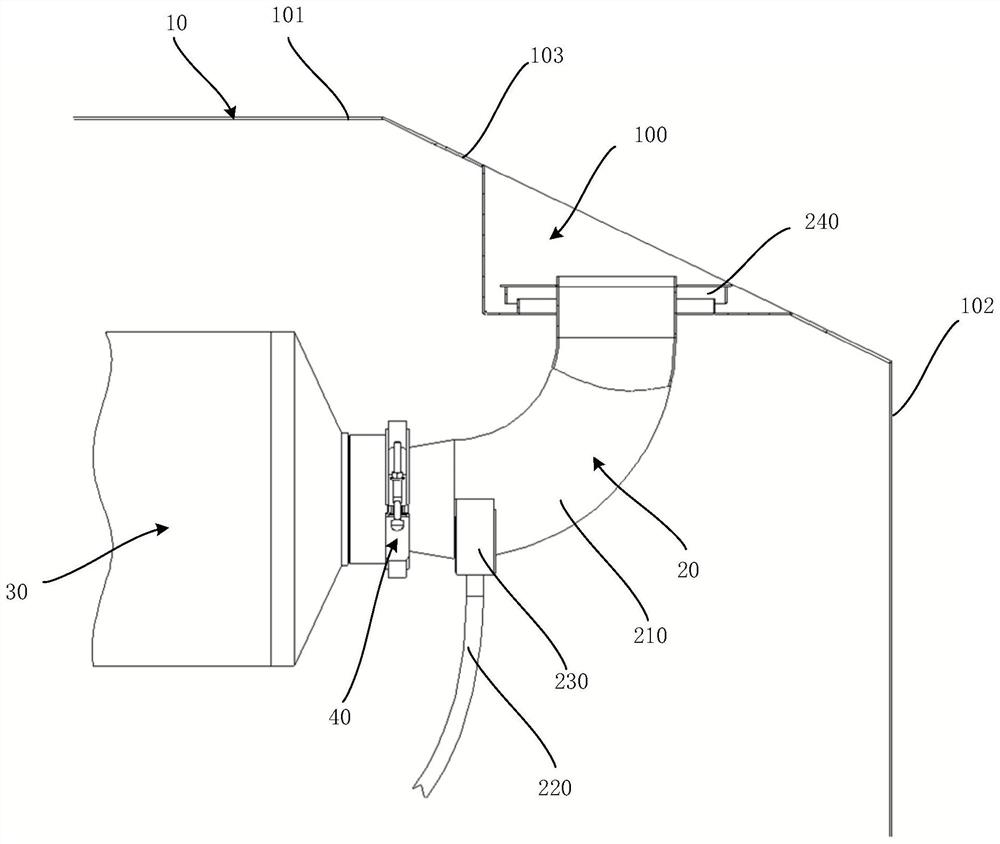

[0036] figure 1 Shown in is the structural diagram of the vehicle body assembly that an embodiment of the present application provides; Please refer to figure 1 .

[0037] This embodiment provides a vehicle body assembly, including:

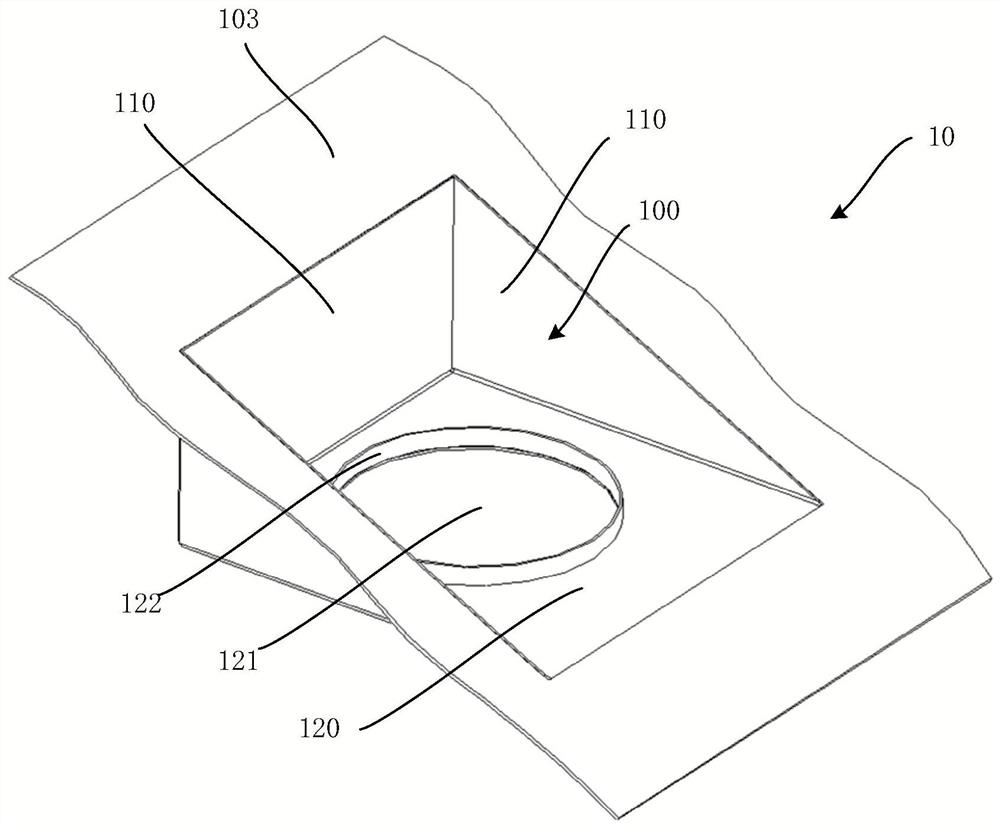

[0038] The vehicle body 10, the surface of the vehicle body 10 is provided with a mounting portion 100 sunken toward the interior of the vehicle body 10;

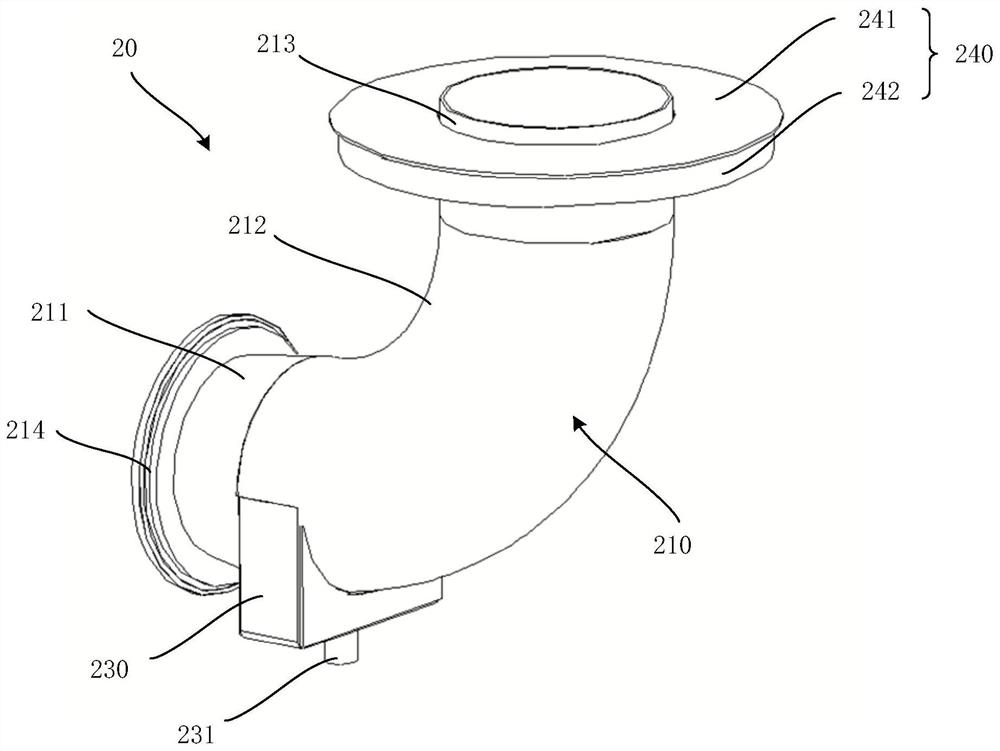

[0039] The exhaust device 20 is used to connect the engine 30 of the vehicle with the external environment, and the air outlet of the exhaust device 20 is disposed in the installation part 100 .

[0040] Specifically, in this embodiment, the installation part 100 can be arranged on the top surface, the side surface or any other plane of the vehicle body 10, as long as the normal exhaust requirements can be met, which is not limited in this embodiment. The shape of the mounting part 100 can also be set according to needs, for example, it can be in the shape of a column, a prism, or the like....

Embodiment 2

[0061] This embodiment provides an engineering vehicle, including an engine and the vehicle body assembly described in Embodiment 1 above, and the engine communicates with the external environment through the exhaust device of the vehicle body assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com