Simulation bomb launcher

A technology of a launcher and a simulated bomb, which is applied to weapon accessories, weapon types, weapons without explosives, etc., can solve the problems of hoop adjustment, the base cannot be folded, and it is inconvenient to move, so as to facilitate clamping and reduce flying injuries. risk, the effect of easy folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

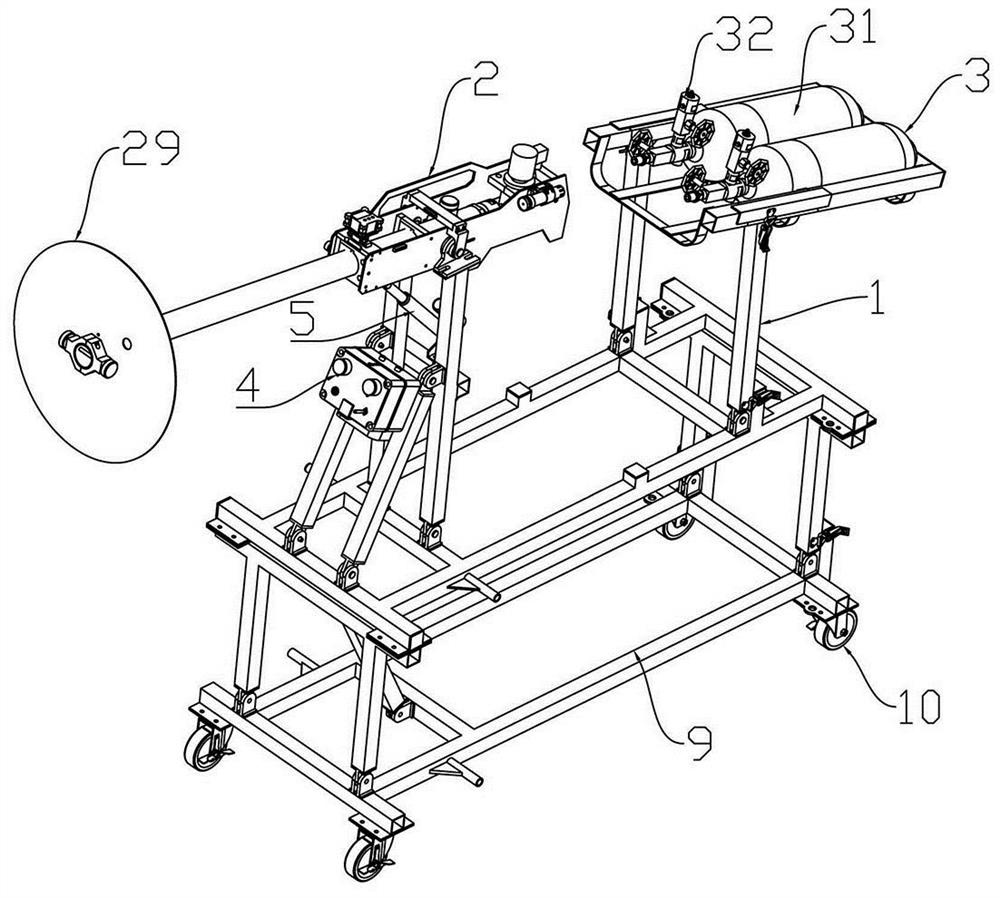

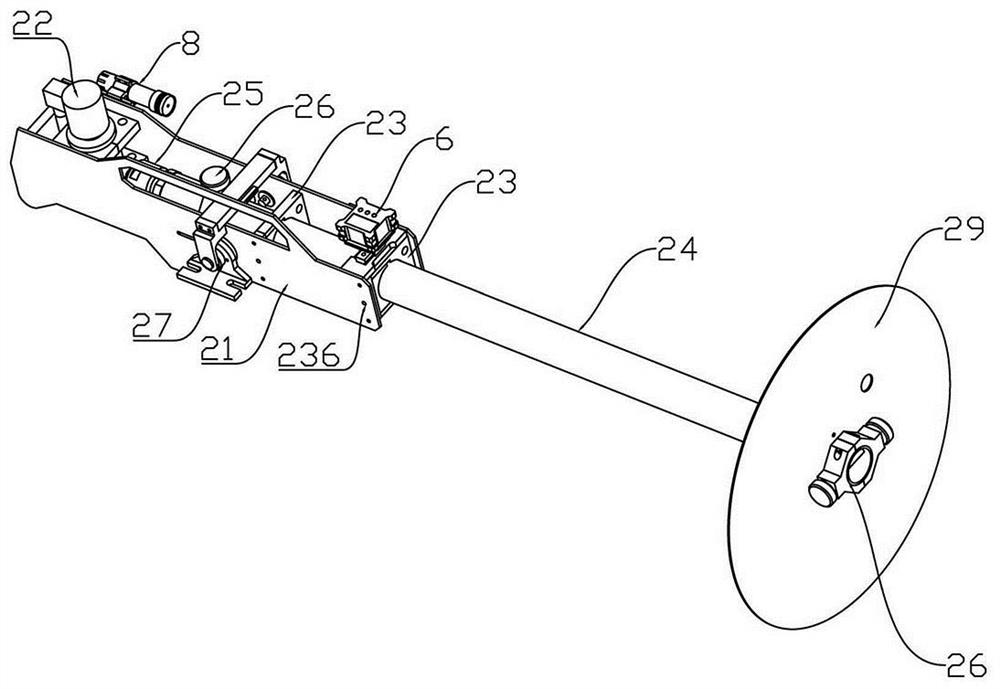

[0065] See attached figure 1 , 3 , the launch tube bracket 21, the solenoid valve 22, the launch tube fastening mechanism 23, the launch tube 24 that matches the simulated bomb (the end of the launch tube 24 away from the launch tube bracket 21 has a pin hole), the air inlet joint 25, the bearing seat 27. After assembling the digital display angle meter 6, the level meter 7, the laser distance meter 8, the gas storage device 3, the support device 1, the controller 4, and the height-increasing device 9, the fastening bolts are connected in the thread adjustment through hole 236 and pushed up. Tighten the second clamping plate 232, thereby fixing the launch tube 24. The baffle plate 29 is sleeved on the inside of the pin hole of the launch tube 24, the simulated projectile is penetrated in the launch tube 24 and the pin hole of the simulated projectile coincides with the pin hole of the launch tube 24, and in the pin hole of the launch tube 24 The first structural form of the ...

Embodiment 2

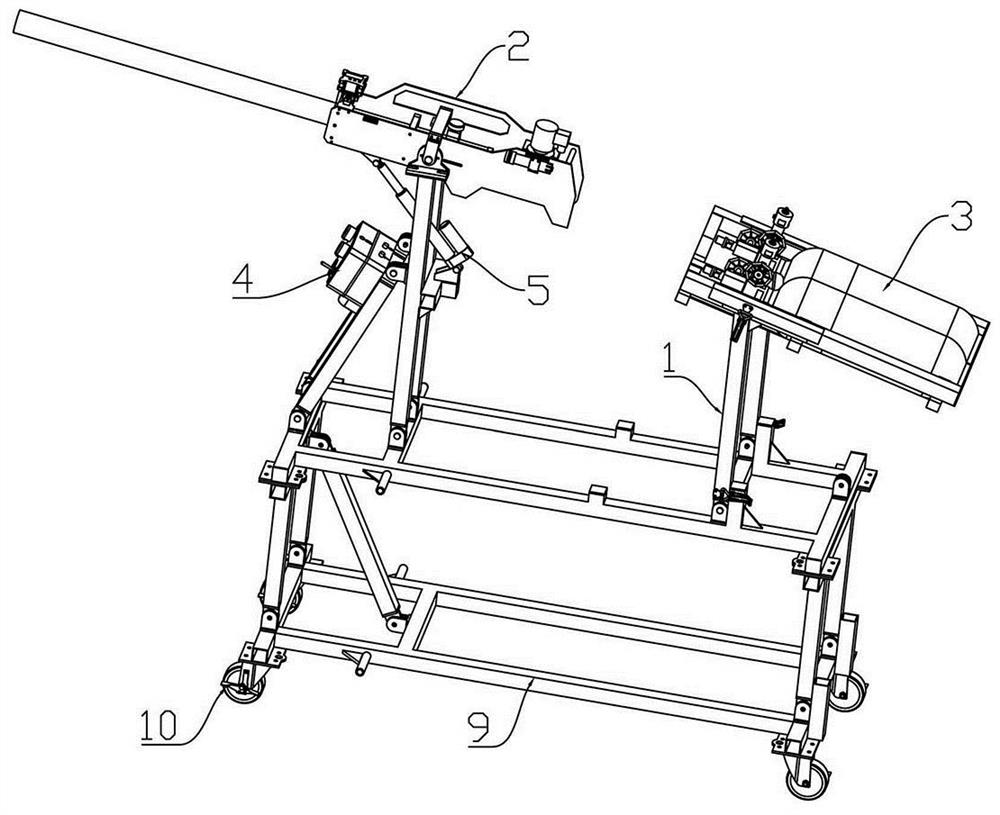

[0067] See attached figure 2 , 5 , the launch tube bracket 21, the solenoid valve 22, the launch tube fastening mechanism 23, the launch tube 24 matching the simulated bomb (the end of the launch tube 24 close to the air inlet joint 25 has a pin hole), the air intake joint 25, the bearing seat 27. After assembling the digital display angle meter 6, the level meter 7, the laser distance meter 8, the gas cylinder group 31, the support device 1, the controller 4, and the height-increasing device 9, fix the inner jacket 28 at intervals on the outer circumference of the launch tube 24 , the spacing distance of each inner jacket 28 is the same as the distance between each launch tube fastening mechanism 23, and the inner jacket 28 on the launch tube 24 is respectively embedded in the first clamping plate 231 and the first clamping plate 231 in the launch tube fastening mechanism 23. In the clamping groove 235 of the second clamping plate 232 , fastening bolts are connected in the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap