Adjusting clamping block structure for automobile tool

A technology for tooling and automobiles, which is applied in the direction of workpiece clamping devices, workbenches, manufacturing tools, etc. It can solve the problems that the direction cannot be changed at will, the clamping block cannot clamp the object, and the clamping block angle is not equal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

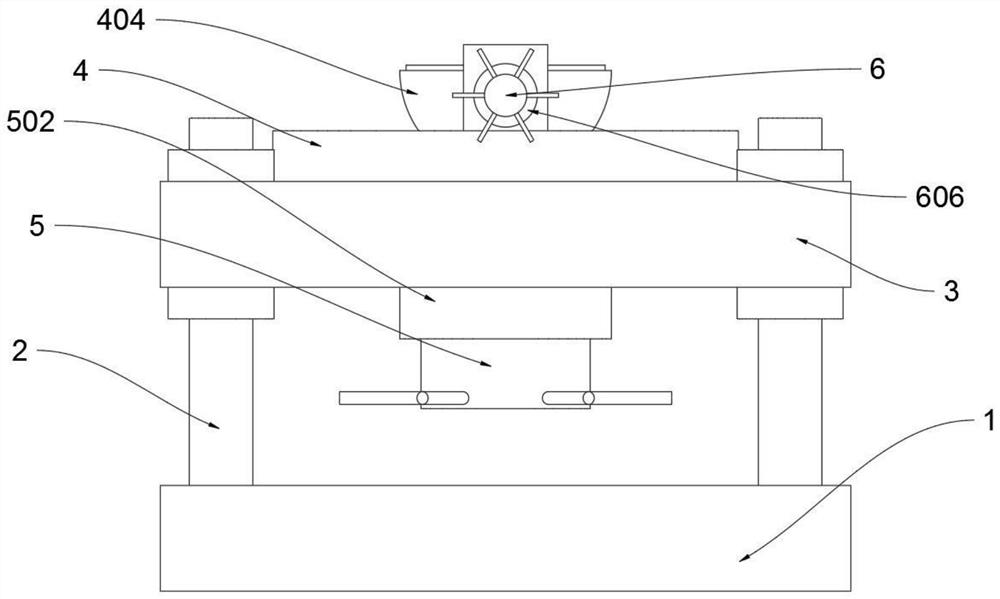

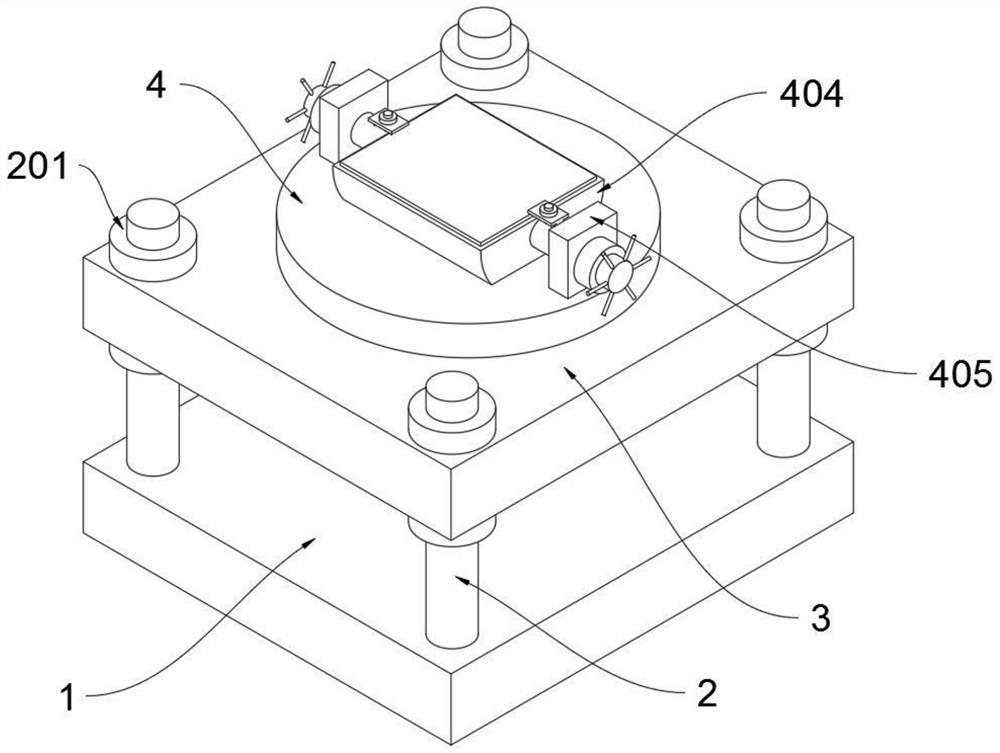

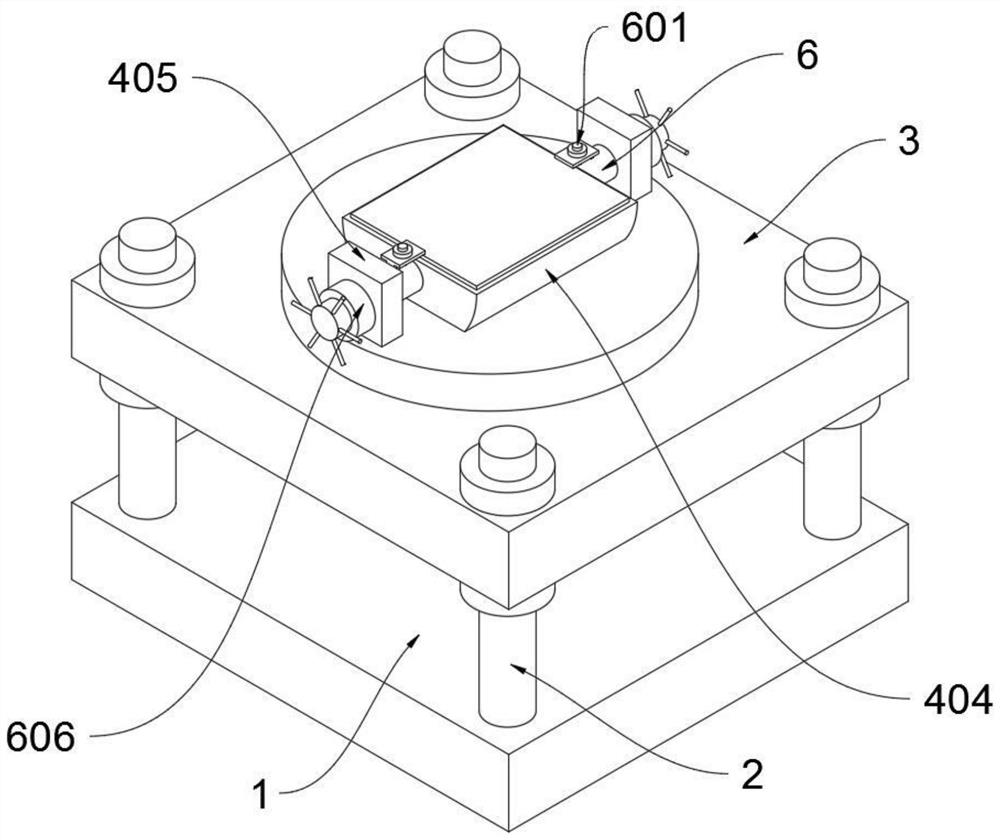

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The invention provides an adjusting clip block structure for automobile tooling, which includes a fixed plate 1; left and right mutually symmetrical thread columns 2 are fixedly installed at the front and rear ends of the top of the fixed plate 1; Symmetrical groove; the threaded column 2 includes a bearing ring 201, the upper and lower ends of the four threaded columns 2 are equipped with a circular bearing ring 201, the bottom of the upper end bearing ring 201 is closely attached to the top of the lifting plate 3, and the lower end carries The top of the ring 201 is closely attached to the bottom of the lifting plate 3, and the carrying ring 201 is loosened, and the lifting plate 3 can move up and down to adjust the height, and then the lifting plate 3 is fixed with the carrying ring 201. The lifting plate 3 includes a bearing groove 301 and Rotary groove 302, a ring-shaped bearing groove 301 is opened in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com