Construction method of large-span roof steel truss structure

A construction method and steel truss technology, which is applied in the direction of building structure, construction, and building material processing, can solve the problems of small jacking height, poor efficiency and stability, and the inability to efficiently and safely complete the jacking of super-high roof steel trusses. , to achieve the effect of high lifting height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

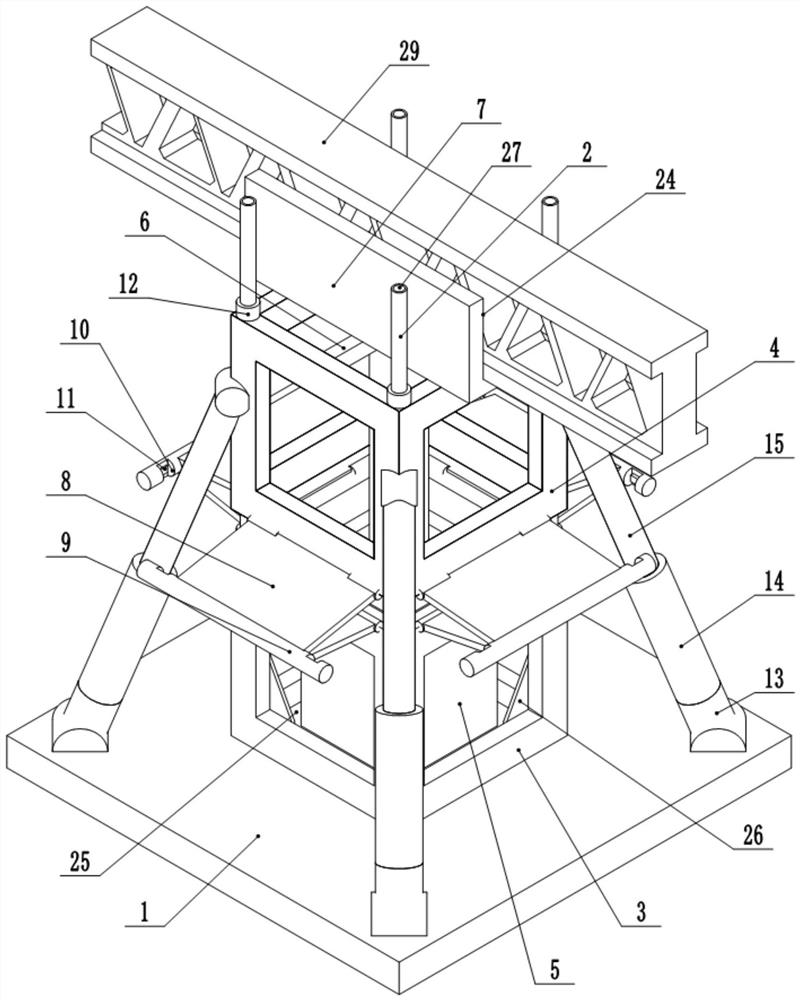

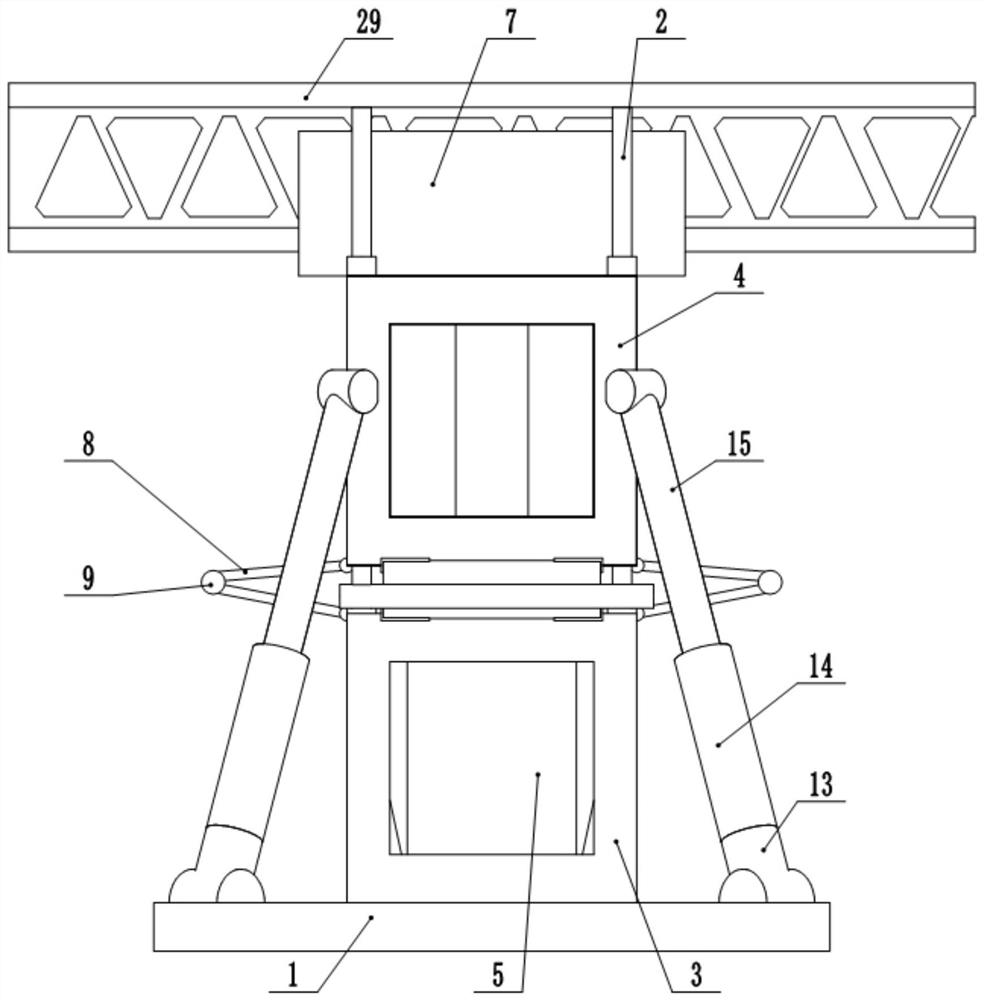

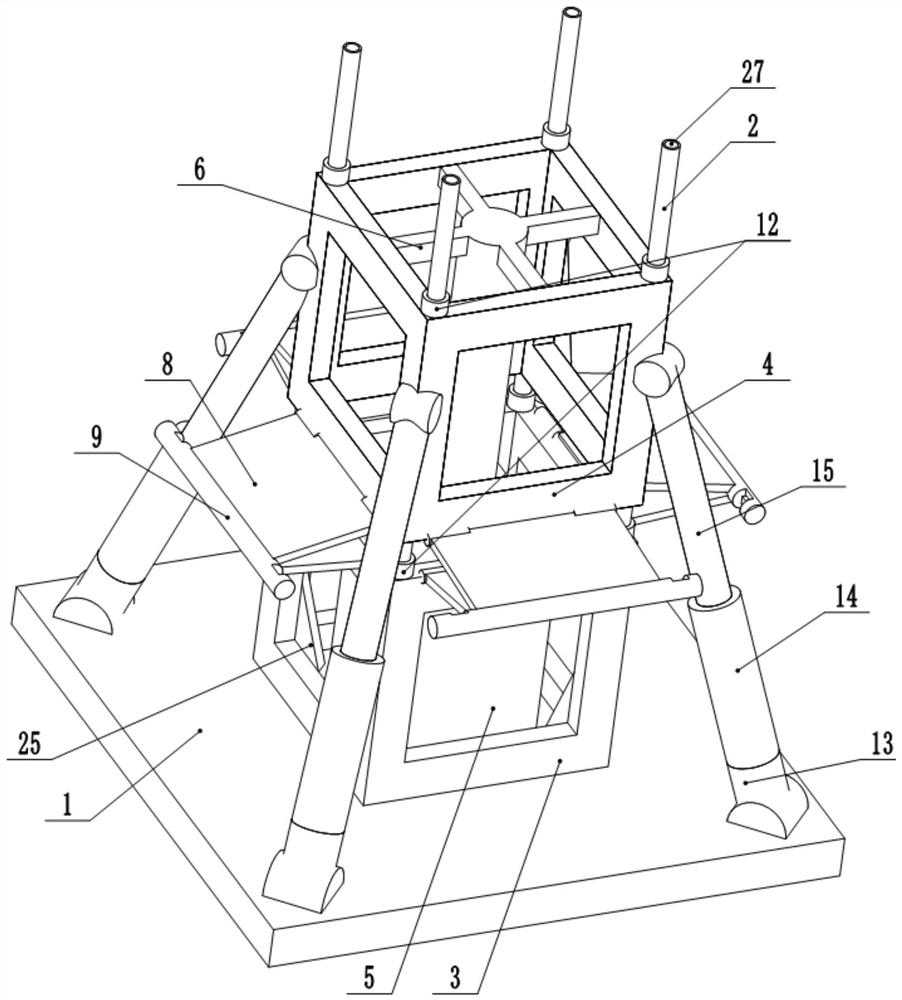

[0047] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 5 , Figure 7 and Figure 8 Shown:

[0048] A construction method for a long-span roof steel truss structure, comprising the following steps:

[0049] 1) Installation of the jacking device: place the jacking device at the installation position, and fix the base 1 on the ground; install the steel truss 29 in the installation groove 24 of the support base 7, and fix the steel truss 29 on the support base 7 superior;

[0050] 2), jacking operation: energize the second electromagnet 12 on the lower support frame 3, utilize the second electromagnet 12 on the lower support frame 3 to fix the lower support frame 3 and the support column 2; start the hydraulic cylinder 5 to The support base 7 and the steel truss 29 are lifted together, and the hydraulic cylinder 5 also pushes the upper support frame 4 to move upward; when the stroke distance of the hydraulic cylinder 5 reaches the maximum, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com