Method and system for needle tip alignment degree detection based on deep learning

A technology of deep learning and detection method, which is applied in the field of image processing, can solve the problems of poor detection accuracy of needle tip alignment and achieve good robustness and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

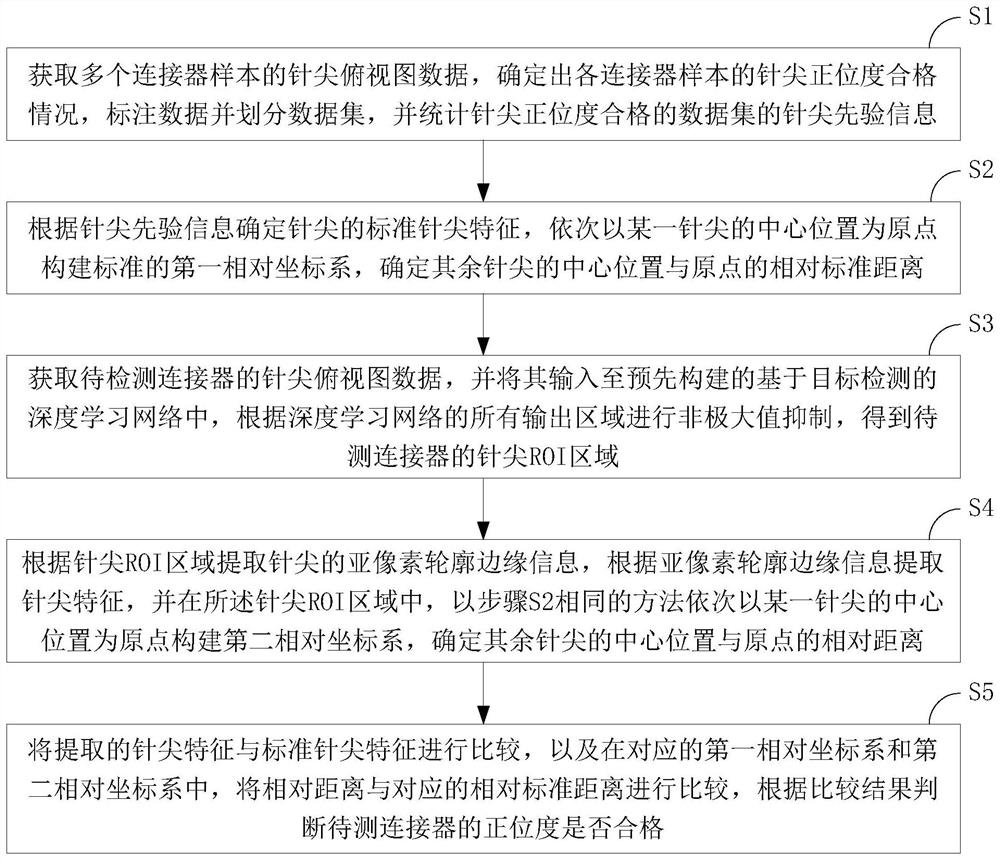

[0048] The deep learning-based needle tip alignment detection method described in the embodiment of the present invention is as follows: figure 1 shown, including the following steps:

[0049] Step S1 , acquiring the needle tip top view data of the plurality of connector samples, determining the qualified condition of the needle tip alignment of each connector sample according to the needle tip top view data, labeling the data and dividing the data set according to the qualified condition of the needle tip alignment, and collecting statistics The prior information of the needle tip of the data set with qualified needle tip alignment;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com