A kind of boron carbide bullet-proof board with multi-bomb and multi-curved surface and preparation method thereof

A bulletproof insert, boron carbide technology, applied in chemical instruments and methods, protective equipment, protective equipment and other directions, can solve the problems of large dent deformation, poor anti-polyelasticity, poor product stability, etc. The bullet has more kinetic energy, strong anti-multi-elasticity, and good hardness consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] An anti-multi-bomb multi-curved boron carbide bulletproof insert, the anti-multi-bounce and multi-curved boron carbide bulletproof insert comprises a crack arrest layer, a ceramic layer, a transition layer, a PE layer and a reducing concave layer;

[0064] The crack arresting layer is aramid fabric with an areal density of 195-200g / m 2 ;

[0065] The ceramic layer is a pressureless sintered boron carbide ceramic plate, which is prepared by powder nanotechnology and formula optimization, and has a thickness of 6mm;

[0066] The transition layer is a titanium plate with a thickness of 0.5mm;

[0067] The PE layer is a combination of PEUD cloth and film tape, and the areal density is: 9.0-10.5kg / m 2 ;

[0068] The sag-reducing layer is selected from nanoporous PPA, with a thickness of 3-5mm;

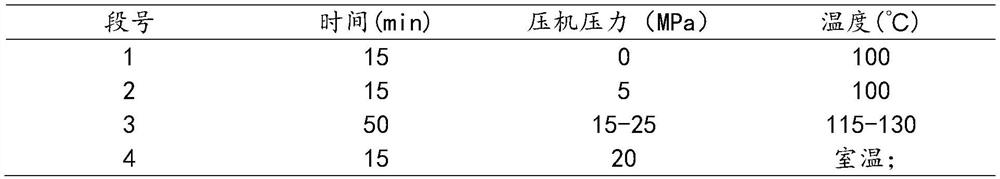

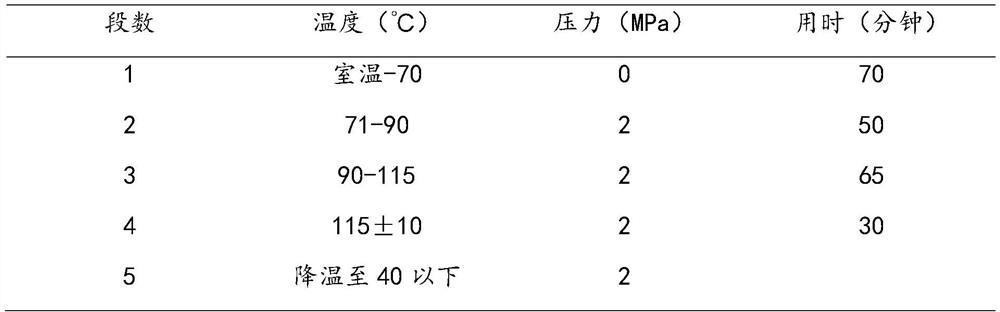

[0069] The preparation method of the described PE layer: at normal temperature, the film tape (area density 5-10kg / m 2 ) and PEUD cloth (area density 2-5kg / m 2 ) were put into...

Embodiment 2

[0091] An anti-multi-bomb multi-curved boron carbide bulletproof insert, the anti-multi-bounce and multi-curved boron carbide bulletproof insert comprises a crack arrest layer, a ceramic layer, a transition layer, a PE layer and a reducing concave layer;

[0092] The crack arresting layer is aramid fabric with an areal density of 195-200g / m 2 ;

[0093] The described ceramic layer is a pressureless sintered boron carbide ceramic plate, which is prepared by using powder nanotechnology and formula optimization, with a thickness of 6 mm; the pressureless sintered boron carbide ceramic is made of the following raw materials ( Brand BC18): 100 parts of 0.8um boron carbide, sintering aids (5 parts of carbon nanotubes, 3 parts of 0.3um yttrium trioxide; 5 parts of 0.5um titanium carbide), binder (5 parts of polyvinyl alcohol, hydroxypropyl 5 parts of methyl cellulose), dispersant (0.2 part of KH560, 0.3 part of PEG4000), plasticizer (0.05 part of DEP);

[0094] The preparation met...

Embodiment 3

[0104] An anti-multi-bullet multi-curved boron carbide bulletproof insert, the anti-multi-bounce and multi-curved boron carbide bulletproof insert includes a crack arrest layer, a ceramic layer, a transition layer, a PE layer and a dent reduction layer arranged in sequence from the ballistic panel to the back plate Floor;

[0105] The crack arresting layer is aramid fabric with an areal density of 210-230g / m 2 ;

[0106] The described ceramic layer is the whole plate of pressureless sintered boron carbide ceramics, which is prepared by powder nanotechnology and formula optimization, and the thickness is 10mm; the described pressureless sintered boron carbide ceramics are made of the following raw materials ( Grade BC20): 100 parts of 1.0um boron carbide, sintering aids (5 parts of silicon carbide whiskers, 10 parts of 0.5um silicon carbide; 3 parts of 0.3um yttrium trioxide, 1 part of 1.0um titanium carbide, 0.5um titanium boride) 1 part), binder (2 parts of phenolic resin, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com