Wear-resisting plate suitable for bulk cargo cabin lining

A technology of wear-resistant plates and cabins, applied in the field of wear-resistant plates, can solve the problems of large steel plates, high replacement costs, troublesome maintenance, etc., and achieve the effects of reducing hull load, reducing maintenance and replacement costs, protection and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

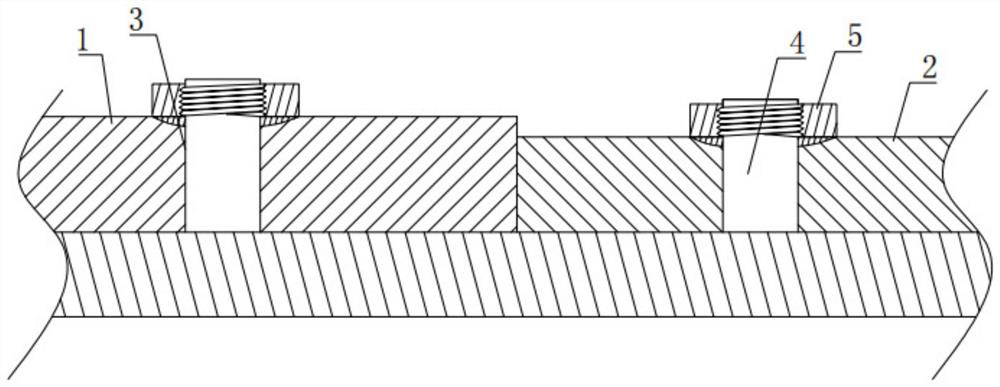

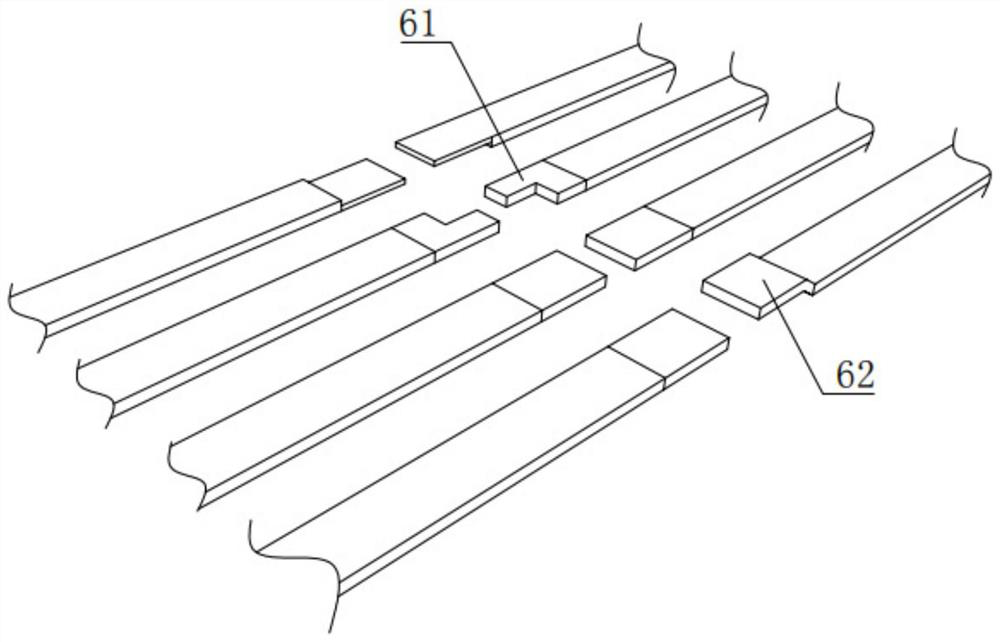

[0022] A wear plate suitable for the lining of bulk cargo ships, such as figure 1 As shown, it includes a wear-resistant thick plate 1 and a wear-resistant thin plate 2 arranged on the steel plate in the cabin. The thickness of the wear-resistant thick plate 1 is twelve millimeters and is located in the cabin directly affected by the impact, and the wear-resistant thin plate 2 is ten millimeters. And it is located in the indirect impact part of the cabin, and each wear-resistant thick plate 1 and wear-resistant thin plate 2 are engaged with each other to form a whole that completely covers the steel plate in the cabin;

[0023] Such as figure 1 As shown, the thickness of the wear-resistant plate is required to be 10mm and 12mm, which not only retains the impact resistance strength requirements of the protective layer, but also reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com