Focusing mechanism

A lens and cavity technology, applied in the field of optics, can solve the problems of high manufacturing cost and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

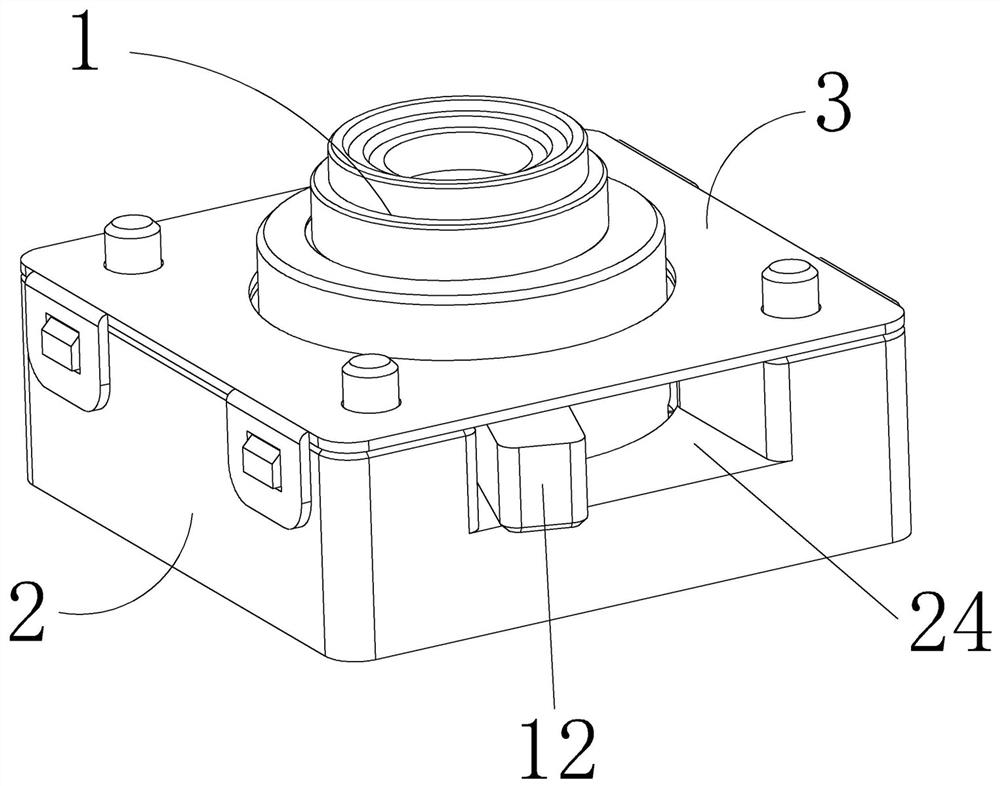

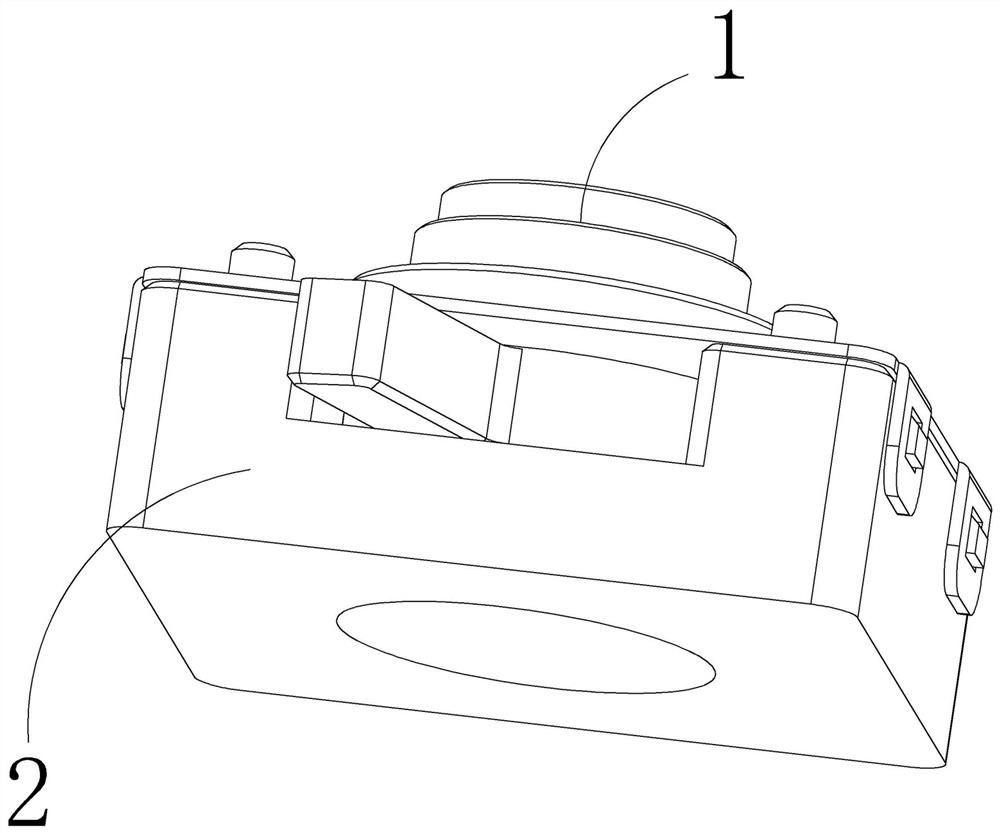

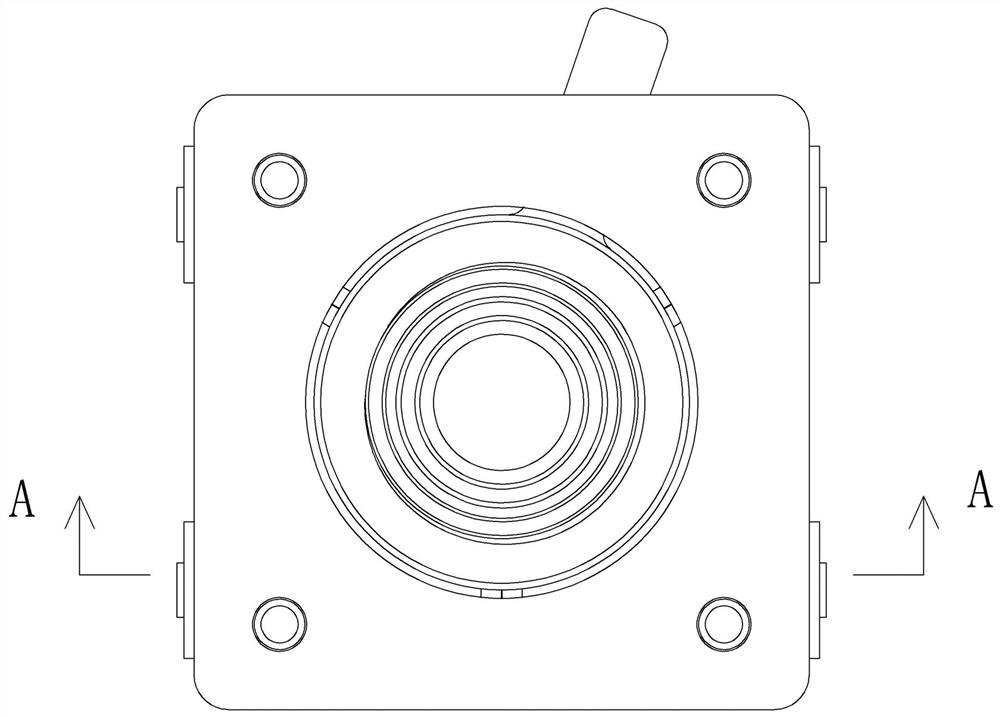

[0036] see Figure 1 to Figure 4 , in this embodiment, a focusing mechanism is proposed, including a lens 1 and a mount 2 .

[0037] Such as Figure 5 to Figure 7 As shown, the support 2 has a receiving cavity 21 . Wherein, the lens 1 is rotatably and slidably disposed in the accommodating cavity 21 .

[0038] In order to facilitate the installation of the lens 1 , the accommodating cavity 21 is shaped like a cylinder, and the accommodating cavity 21 runs through the top surface of the support 2 . Wherein, the inner diameter of the accommodation cavity 21 is larger than the maximum outer diameter of the lens 1 .

[0039] Since the focusing mechanism needs to be used in conjunction with projection lamps, cameras and other equipment, considering the propagation of light, the support 2 is provided with a light-transmitting hole 22 coaxial with the accommodating cavity 21, wherein the light-transmitting hole 22 runs through the support 2 The bottom surface is in communication ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com